SnoWarrior

Lifetime Member

- Joined

- Jan 13, 2005

- Messages

- 438

- Location

- Long Island, NY

- Country

- USA

- Snowmobile

- 2024 Sidewinder L-TX LE

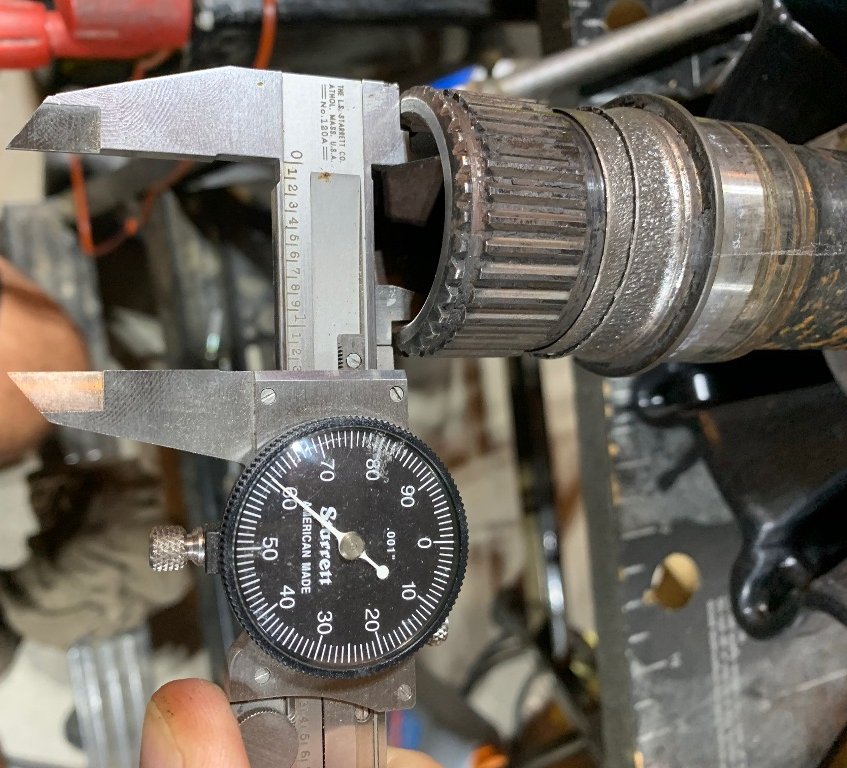

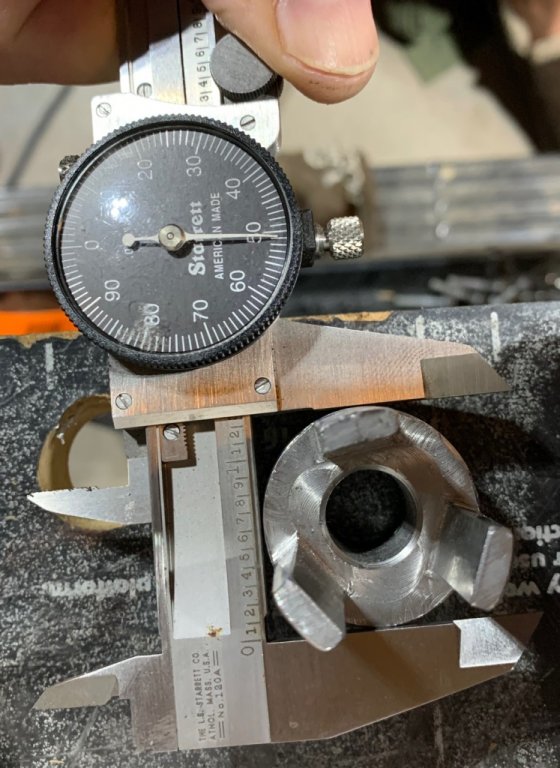

Ok, old driveshaft and bearing were toast after last season. Received a new driveshaft and bearing about 3 weeks ago from my dealer. Got it installed and went to put the BOP driveshaft saver in…..ohh noo Mr. Bill! NO FIT

The new driveshaft has a smaller inside diameter than the one that I removed. (2018)

Normally, I would blame this on Steve, but I have 0% OCD, so I can’t.

(I hope he will let me ride in Maine this year. I think Canada is going to be a bust.)

Anyway, I called my dealer; he said he never had one he could not install.

Then I called Travis, pretty much the same answer. This Cat DNA is a pain in my ***.

So, if you get a new driveshaft, make sure you measure it before you order the driveshaft saver. Travis said he might have to take some and have them cut down. If anyone has a relatively new shaft, maybe check it, and see if it has a smaller diameter. (Maybe I just got a “freak” shaft).

I will take My shaft saver to a machine shop and have it modified. Looks like I need to remove about .023 of material.

New Shaft – 1.237

Old shaft – 1.260

BOP Saver – 1.250

The new driveshaft has a smaller inside diameter than the one that I removed. (2018)

Normally, I would blame this on Steve, but I have 0% OCD, so I can’t.

(I hope he will let me ride in Maine this year. I think Canada is going to be a bust.)

Anyway, I called my dealer; he said he never had one he could not install.

Then I called Travis, pretty much the same answer. This Cat DNA is a pain in my ***.

So, if you get a new driveshaft, make sure you measure it before you order the driveshaft saver. Travis said he might have to take some and have them cut down. If anyone has a relatively new shaft, maybe check it, and see if it has a smaller diameter. (Maybe I just got a “freak” shaft).

I will take My shaft saver to a machine shop and have it modified. Looks like I need to remove about .023 of material.

New Shaft – 1.237

Old shaft – 1.260

BOP Saver – 1.250

TPAY243

Lifetime Member

- Joined

- Apr 14, 2013

- Messages

- 834

- Age

- 57

- Location

- Northern Wis

- Country

- USA

- Snowmobile

- 2020 Yamaha Sidewinder LTX SE

Maybe it's a up dated shaft, what kind of fit does the bearing have on the O.D.

SnoWarrior

Lifetime Member

- Joined

- Jan 13, 2005

- Messages

- 438

- Location

- Long Island, NY

- Country

- USA

- Snowmobile

- 2024 Sidewinder L-TX LE

Maybe it's a up dated shaft, what kind of fit does the bearing have on the O.D.

Bearing fit snug on the shaft. Dealer is inquiring if there were any changes to the shaft.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Someone at corporate must have seen how awsome it works and had the shaft dimensions changed.

No breakdowns, no new sled sales

No breakdowns, no new sled sales

TPAY243

Lifetime Member

- Joined

- Apr 14, 2013

- Messages

- 834

- Age

- 57

- Location

- Northern Wis

- Country

- USA

- Snowmobile

- 2020 Yamaha Sidewinder LTX SE

Ya no doubt Clutch Master

Mine I got end of March after being back ordered all winter the bop still fits but tight. Bearing is still sloppy fit.

eightpilot

Expert

- Joined

- Mar 17, 2009

- Messages

- 437

- Location

- Mosinee WI

- Country

- USA

- Snowmobile

- 2021 Thundercat

- LOCATION

- Mosinee WI

Got 5k boosted miles out of my first shaft... If i get 5K out of the replacement I'll be happy.... Put a few dimples in it before tapping on the bearing...

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,182

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

Maybe cat updated the part

If they can’t hit the numbers on O.D. No reason to believe they can on the I.D.Maybe cat updated the part

RAMSOMAIR

TY 4 Stroke God

True story, its likely just another one that got through the awesome QC process.

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,182

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

If they can’t hit the numbers on O.D. No reason to believe they can on the I.D.

good point. That being said. Yamaha and textron aren’t stupid, so one would assume they have switched suppliers with the amount of warranty claims there were on driveshafts. Then again, when you assume things.....

yamamarc

TY 4 Stroke God

- Joined

- Sep 29, 2013

- Messages

- 3,051

- Location

- Massey Ontario

- Country

- Canada

- Snowmobile

- 2019 zr9000 Ltd

I have a new driveshaft coming for a customer hopefully this week!!

I'll report back once I get it and measure it.

The customer's original driveshaft had the bearing spin on the shaft also!!

He told me to keep the worn shaft so I am going to have it spray welded and machined as a spare if someone needs one during the season ill have one on hand!! I will be doing a shaft exchange for there worn one plus the cost of the spray welding/machining

I'll report back once I get it and measure it.

The customer's original driveshaft had the bearing spin on the shaft also!!

He told me to keep the worn shaft so I am going to have it spray welded and machined as a spare if someone needs one during the season ill have one on hand!! I will be doing a shaft exchange for there worn one plus the cost of the spray welding/machining

Last edited:

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,508

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

IMO, the million dollar question is, were the shafts machined (no matter who the supplier was/is) to Cat print?! For me, it would be hard to believe this whole problem (shaft spinning inside bearing) has been caused by the supplier not machining shafts to specification (ie blueprint). Therefore, as I am holding fast to believing, this problem is a DESIGN problem and I place the blame and responsibility squarely on the shoulders of Arctic Cat engineering.good point. That being said. Yamaha and textron aren’t stupid, so one would assume they have switched suppliers with the amount of warranty claims there were on driveshafts. Then again, when you assume things.....

It will be interesting to learn if now the shaft has a smaller ID via design change, or is it a shaft that was not machined to print?

The mess continues.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

IMO, the million dollar question is, were the shafts machined (no matter who the supplier was/is) to Cat print?! For me, it would be hard to believe this whole problem (shaft spinning inside bearing) has been caused by the supplier not machining shafts to specification (ie blueprint). Therefore, as I am holding fast to believing, this problem is a DESIGN problem and I place the blame and responsibility squarely on the shoulders of Arctic Cat engineering.

It will be interesting to learn if now the shaft has a smaller ID via design change, or is it a shaft that was not machined to print?

The mess continues.

Exactly!

More than likely the inside diameter has a fairly large production tolerance and is just a fluke IMO. Unfortunately yes....the mess continues

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,756

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

Well clearly they have changed suppliers or the design of the part. Thanks for posting to make us aware.

The thickness of the original shaft was pretty flimsy.

Nice of AC to post or make their customers aware of a part upgrade........

MS

The thickness of the original shaft was pretty flimsy.

Nice of AC to post or make their customers aware of a part upgrade........

MS

Similar threads

- Replies

- 6

- Views

- 3K

- Replies

- 36

- Views

- 6K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.