Boston RX1

TY 4 Stroke Master

I have a quick question that i hope someone can answer. I know you are recommending the 6.9's but I have a chance to pickup a brand new pair of 5.7's, free. I am about 10% off trail. How much different are the two skis as far as trail performance?

RAMSOMAIR

TY 4 Stroke God

grab them!

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

First Oil Change - Yamaha recommends 500 miles

PART 1- Draining the engine block:

I was lucky to get on 550 miles on her before this big meltdown. So I decided to do the first oil change. This is an early change at 500 miles(recommended) that is only for a new engine. Typically going forward, I change all my 4s sleds once per season(FALL I prefer) with filter. Yamaha says the filter only needs to be changed every 12,500 miles but I find that abit ridiculous. Makes much more sense to do them both when there IMO.

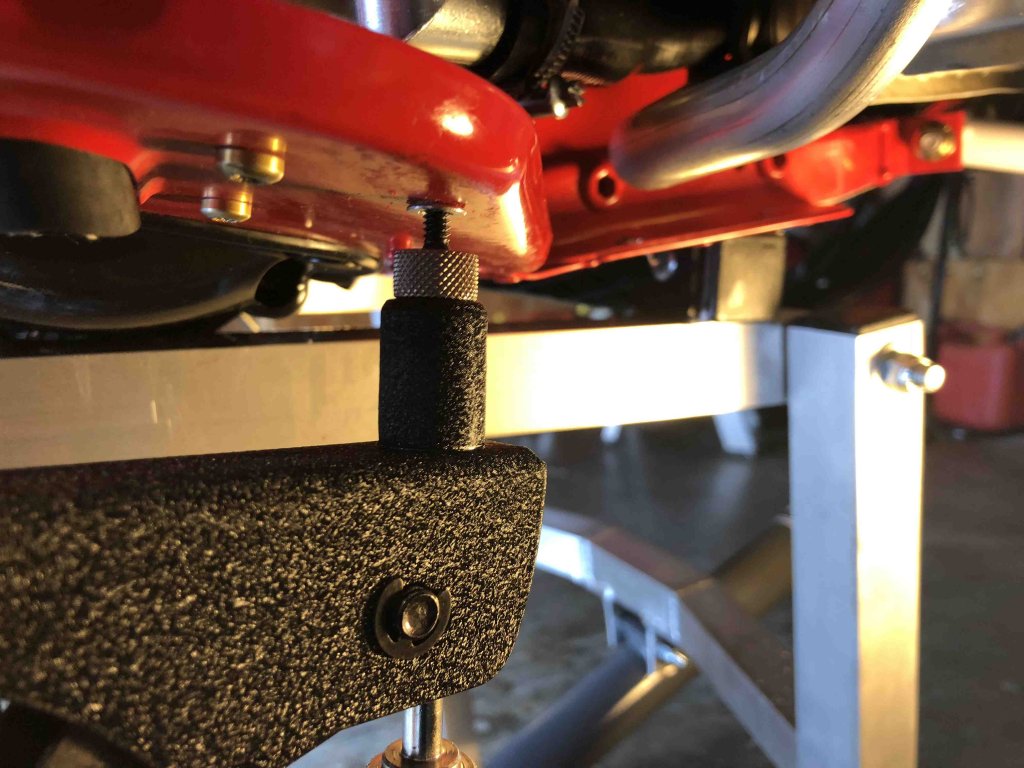

First steps are all under the sled. Warm engine to operating temp, remove bottom plate, remove allen bolt drain plug and allow to drain.(TIP: loosen long allen bolt first, allowing oil to seep some, have pan ready below. Then remove entirely to drain fully)

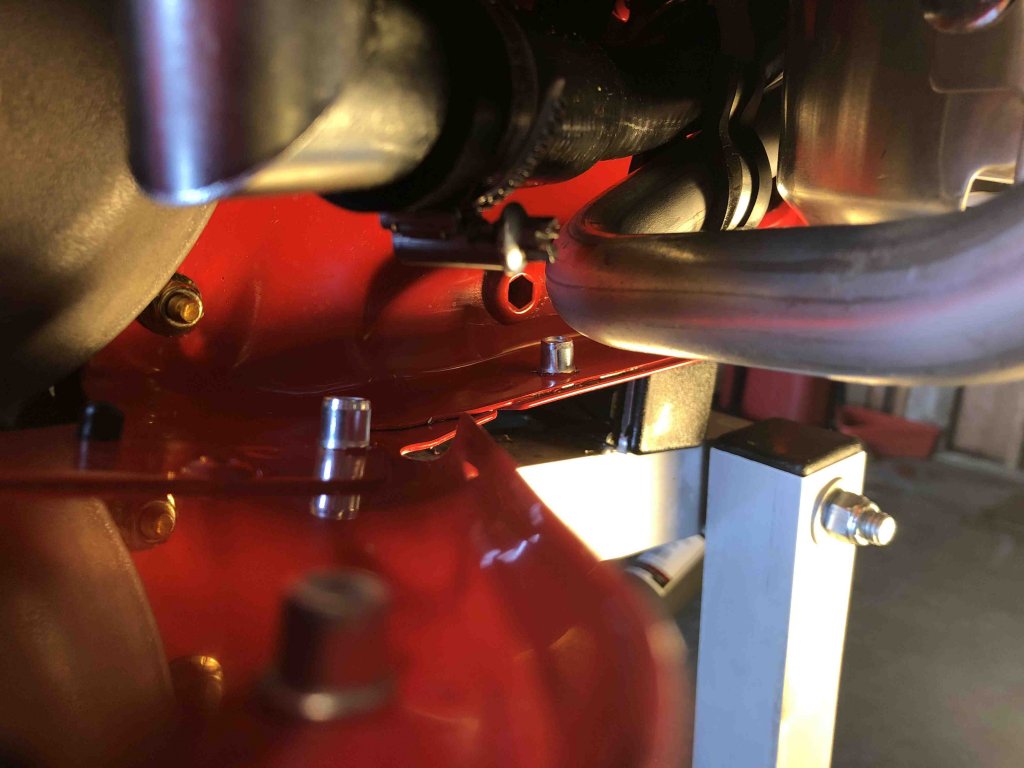

Loosen filter, allow oil to seep some before removing filter entirely.

IMPORTANT: Check to be sure O ring/Gasket on filter has come off engine block.

After block is drained completely, reinstall drain Allen bolt(I reused the stock compression washer with no issue) and then install new filter. Lube the O ring on new filter with a coating of oil. Reinstall bottom plate.

Remove bottom plate

T30 Torx socket to remove bottom plate

Wonderful access to drain plug & Filter

Allen socket on engine drain plug bolt

Crack loose filter, let it seep for abit before removing entirely

K&N oil filters come with a nice welded on 17mm NUT-Couldn't be any easier!

99% of the time, the rubber O ring/gasket from stock oil filter will STICK to engine block, be sure to remove it!

Video of K&N easy filter install....

PART 1- Draining the engine block:

I was lucky to get on 550 miles on her before this big meltdown. So I decided to do the first oil change. This is an early change at 500 miles(recommended) that is only for a new engine. Typically going forward, I change all my 4s sleds once per season(FALL I prefer) with filter. Yamaha says the filter only needs to be changed every 12,500 miles but I find that abit ridiculous. Makes much more sense to do them both when there IMO.

First steps are all under the sled. Warm engine to operating temp, remove bottom plate, remove allen bolt drain plug and allow to drain.(TIP: loosen long allen bolt first, allowing oil to seep some, have pan ready below. Then remove entirely to drain fully)

Loosen filter, allow oil to seep some before removing filter entirely.

IMPORTANT: Check to be sure O ring/Gasket on filter has come off engine block.

After block is drained completely, reinstall drain Allen bolt(I reused the stock compression washer with no issue) and then install new filter. Lube the O ring on new filter with a coating of oil. Reinstall bottom plate.

Remove bottom plate

T30 Torx socket to remove bottom plate

Wonderful access to drain plug & Filter

Allen socket on engine drain plug bolt

Crack loose filter, let it seep for abit before removing entirely

K&N oil filters come with a nice welded on 17mm NUT-Couldn't be any easier!

99% of the time, the rubber O ring/gasket from stock oil filter will STICK to engine block, be sure to remove it!

Video of K&N easy filter install....

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Removing the lower right side Panel

Now that the oil is out of block, we can move over to the oil tank on right side of sled. Typically you will need to make a funnel, remove the footwell bracket(right toe) and drain oil tank into a funnel and out the footwell hole into a drain pan. This is well documented in the owners manual.

I wanted to do a lot more. I wanted to do my chain lube/tension which is always a smart time to do this. So IMO ALL engine oil changes should include a chain lube change/tensioning.

Since I wanted to do some additional work to sled, I wanted more/better access to do a much more thorough job of changing the oil, among other things. I decided I would remove the lower right panel(plastics) which is riveted to the frame with nine 3/16" rivets.

With this panel removed you gain an incredible amount of access to ALL on the right side of these sleds, something I highly recommend. You can use "Rivnuts"/"Nutserts" to allow for easy removal of this panel in the future.

Detailed Video overview of side panel removal

I used a cheapo Harbor Freight rivnut kit, which sorta worked OK but Id recommend something better. These are alum rivnuts in kit( I would use SS rivnuts if I did it again) I went with 10-24 for 3, where the alum is thinnest near right foot, and then had to bump up to next size for the remaining 6, using 1/4-20 rivnuts and then got SS 1/4-20 x 3/4" long bolts.

Now that the oil is out of block, we can move over to the oil tank on right side of sled. Typically you will need to make a funnel, remove the footwell bracket(right toe) and drain oil tank into a funnel and out the footwell hole into a drain pan. This is well documented in the owners manual.

I wanted to do a lot more. I wanted to do my chain lube/tension which is always a smart time to do this. So IMO ALL engine oil changes should include a chain lube change/tensioning.

Since I wanted to do some additional work to sled, I wanted more/better access to do a much more thorough job of changing the oil, among other things. I decided I would remove the lower right panel(plastics) which is riveted to the frame with nine 3/16" rivets.

With this panel removed you gain an incredible amount of access to ALL on the right side of these sleds, something I highly recommend. You can use "Rivnuts"/"Nutserts" to allow for easy removal of this panel in the future.

Detailed Video overview of side panel removal

I used a cheapo Harbor Freight rivnut kit, which sorta worked OK but Id recommend something better. These are alum rivnuts in kit( I would use SS rivnuts if I did it again) I went with 10-24 for 3, where the alum is thinnest near right foot, and then had to bump up to next size for the remaining 6, using 1/4-20 rivnuts and then got SS 1/4-20 x 3/4" long bolts.

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

First Oil Change - Oil Tank

Part 2: Draining the Oil tank:

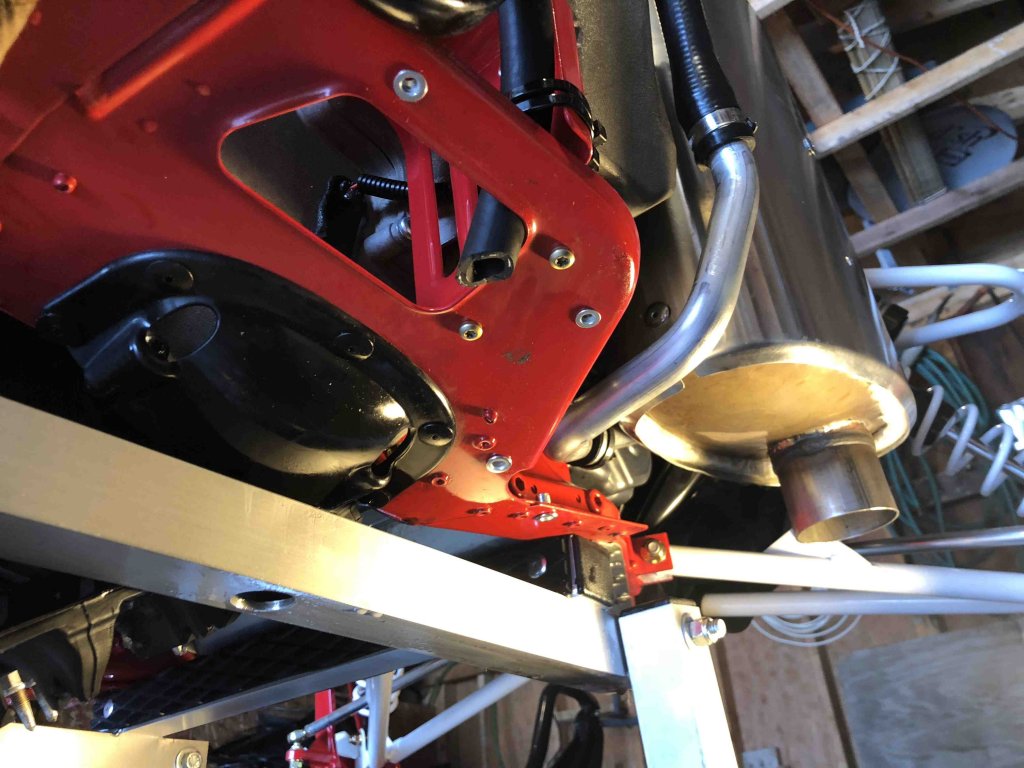

Now that engine block is drained and buttoned up, we can move to the oil tank. With my lower side panel removed, Its very easy to remove the main drain bolt on bottom of oil tank. No funnel needed.

I reused my o-ring which stayed right onto the drain plug.

Once most of tank is drained from the bottom tank plug, I decided I would get ALL the oil out. There are two hoses/tubes right there, that will hold oil in them even after draining block and tank. With lower side panel removed, its simple to now drain these two hoses. This will allow for a 100% complete oil draining of the sled, and IMO should be done.

Drain these hoses/tubes below - See Videos

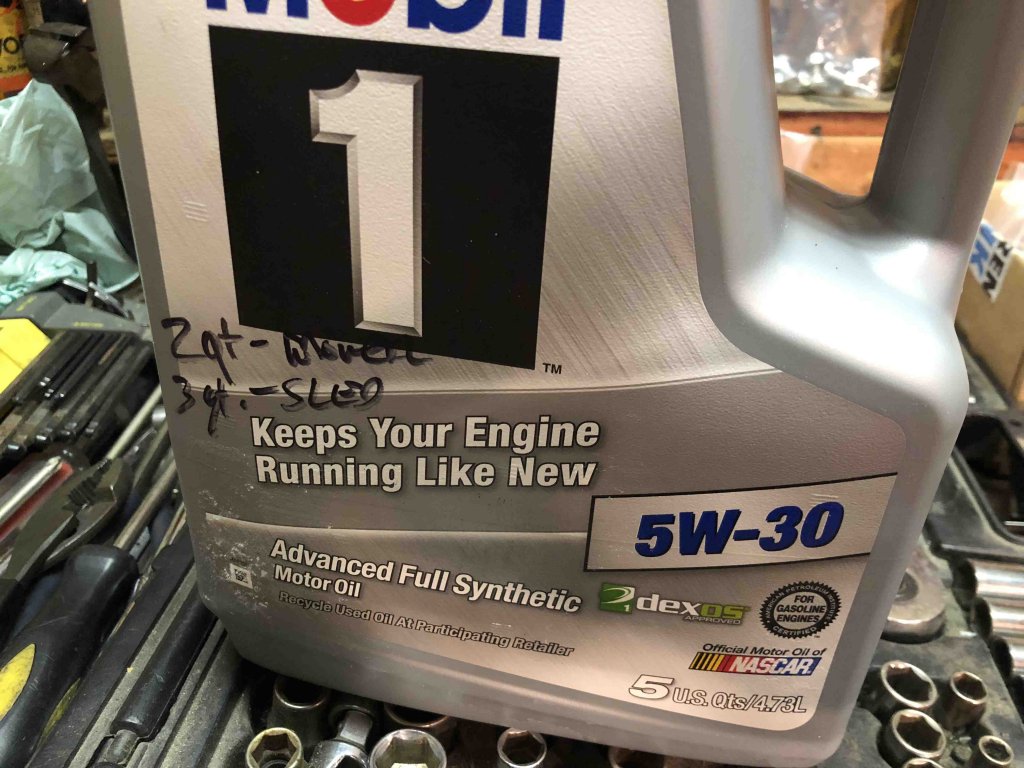

Once all oil is drained from tank and hoses/tubes....reinstall the plug and hoses/tubes. And pour in 3Qts full synthetic mobil 1 5w30(IMO). Start engine(be sure you have everything back together before starting engine) and watch oil light to be sure it goes out within 10 seconds. If all is good with light, check level on tank gauge. With mine it was VERY LOW(stopped engine quickly) as I was able to remove much more oil then if I had not removed tubes/hoses. So i added more oil right away, getting it closer to BOTTOM level line. Then I re-started engine and allowed a full warm up(Oil level will RAISE as engine temp comes up). After fully warm I topped off oil level to the TOP level line(WARM ENGINE)

Part 2: Draining the Oil tank:

Now that engine block is drained and buttoned up, we can move to the oil tank. With my lower side panel removed, Its very easy to remove the main drain bolt on bottom of oil tank. No funnel needed.

I reused my o-ring which stayed right onto the drain plug.

Once most of tank is drained from the bottom tank plug, I decided I would get ALL the oil out. There are two hoses/tubes right there, that will hold oil in them even after draining block and tank. With lower side panel removed, its simple to now drain these two hoses. This will allow for a 100% complete oil draining of the sled, and IMO should be done.

Drain these hoses/tubes below - See Videos

Once all oil is drained from tank and hoses/tubes....reinstall the plug and hoses/tubes. And pour in 3Qts full synthetic mobil 1 5w30(IMO). Start engine(be sure you have everything back together before starting engine) and watch oil light to be sure it goes out within 10 seconds. If all is good with light, check level on tank gauge. With mine it was VERY LOW(stopped engine quickly) as I was able to remove much more oil then if I had not removed tubes/hoses. So i added more oil right away, getting it closer to BOTTOM level line. Then I re-started engine and allowed a full warm up(Oil level will RAISE as engine temp comes up). After fully warm I topped off oil level to the TOP level line(WARM ENGINE)

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

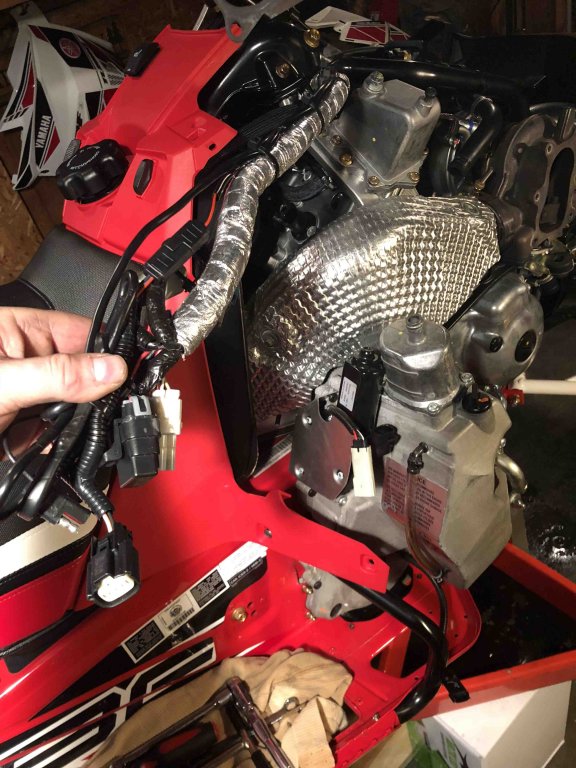

Chaincase

Part 1: Prepare to open up the case

While its not required to drain oil tank when working on chaincase, it sure makes it alot easier. IMO it makes sense to do these two maintenance items at same time. Engine Oil & Chain lube/tensioning.

With oil tank empty, I start by removing the vent hose on top of tank, and unplugging things at bottom of main wire harness(wrapped with heat foil tape) to Speedo sensor,Reverse motor ect. Basically unplug everything down there, and move the entire wire harness up and out of the way.

Alternatively you can open chaincase without draining engine oil if need be, so you would have to take care not to let oil leak out of top vent, and would swing oil tank outward and over without unhooking lowest tube/hose. Much less room to work on things though obviously.

Next step would be to remove the 3 torx screws holding on the shift actuator and its heat shield(also known as the reverse motor)....remove the reverse motor.

Part 1: Prepare to open up the case

While its not required to drain oil tank when working on chaincase, it sure makes it alot easier. IMO it makes sense to do these two maintenance items at same time. Engine Oil & Chain lube/tensioning.

With oil tank empty, I start by removing the vent hose on top of tank, and unplugging things at bottom of main wire harness(wrapped with heat foil tape) to Speedo sensor,Reverse motor ect. Basically unplug everything down there, and move the entire wire harness up and out of the way.

Alternatively you can open chaincase without draining engine oil if need be, so you would have to take care not to let oil leak out of top vent, and would swing oil tank outward and over without unhooking lowest tube/hose. Much less room to work on things though obviously.

Next step would be to remove the 3 torx screws holding on the shift actuator and its heat shield(also known as the reverse motor)....remove the reverse motor.

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Chaincase

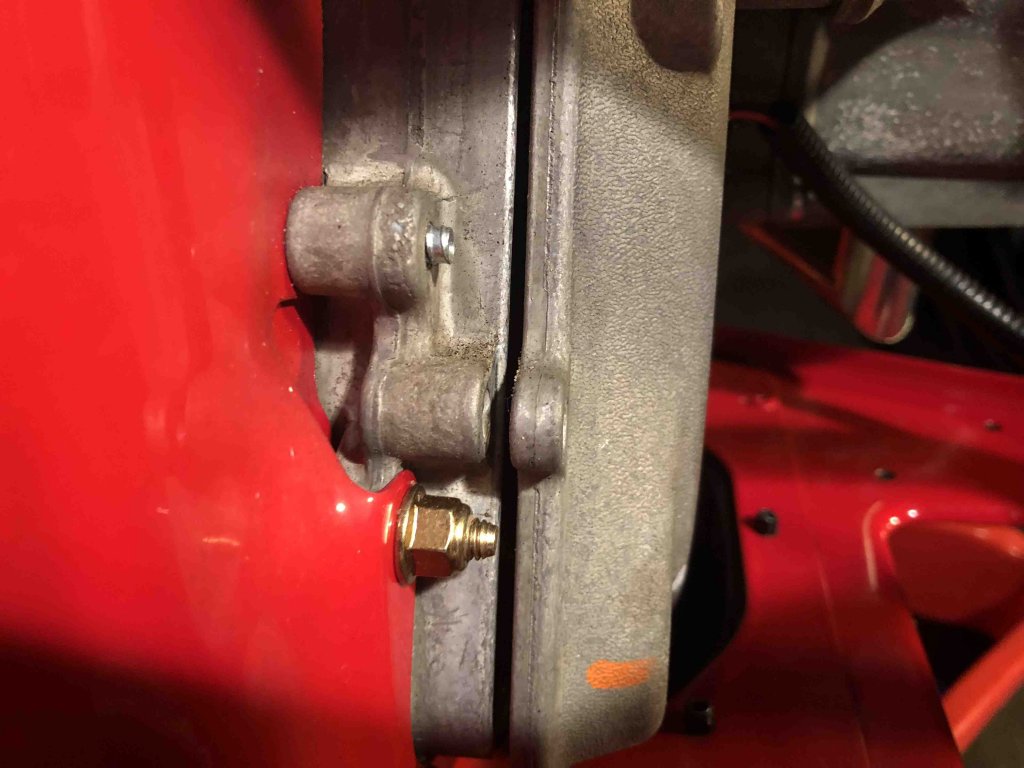

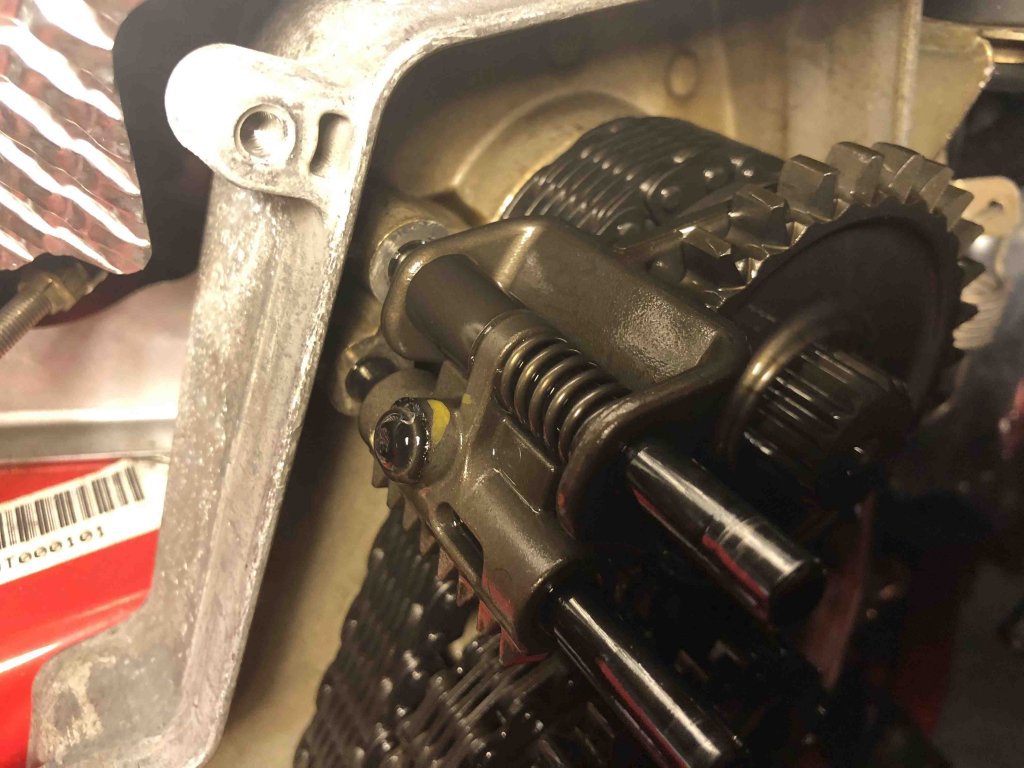

Part 2: Cracking opening the case - external reverse parts removed

With the shift actuator removed(reverse motor) we are ready to crack the case to allow lube to seep out. Using a t30 torx socket and extension, I was able to get squarely on all the black colored chaincase bolts. Be sure you are NOT LOOSENING THE OIL TANK BOLTS.

There is ONE t30 Black bolt that is hard to get onto squarely, and may strip. So this one(near frame over right foot) I used a universal attachment on my 3/8 drive to get on it without worry of stripping.

Crack them open a touch, and allow oil to seep out...pan underneath to catch oil.

While oil is seeping out bottom, we can now remove the remaining parts of the reverse setup. We remove the "extension" first, then the "detent block", and spring. Make note of its orientation, taking pics helps

Part 2: Cracking opening the case - external reverse parts removed

With the shift actuator removed(reverse motor) we are ready to crack the case to allow lube to seep out. Using a t30 torx socket and extension, I was able to get squarely on all the black colored chaincase bolts. Be sure you are NOT LOOSENING THE OIL TANK BOLTS.

There is ONE t30 Black bolt that is hard to get onto squarely, and may strip. So this one(near frame over right foot) I used a universal attachment on my 3/8 drive to get on it without worry of stripping.

Crack them open a touch, and allow oil to seep out...pan underneath to catch oil.

While oil is seeping out bottom, we can now remove the remaining parts of the reverse setup. We remove the "extension" first, then the "detent block", and spring. Make note of its orientation, taking pics helps

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

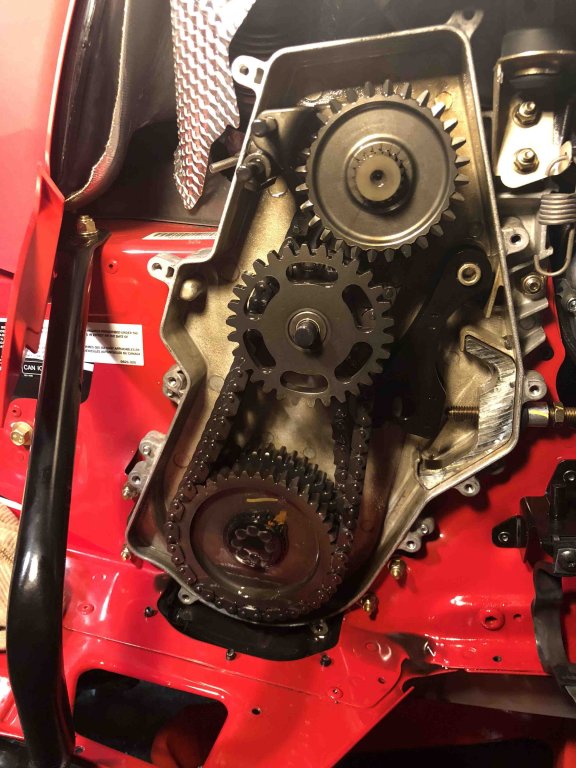

Chaincase

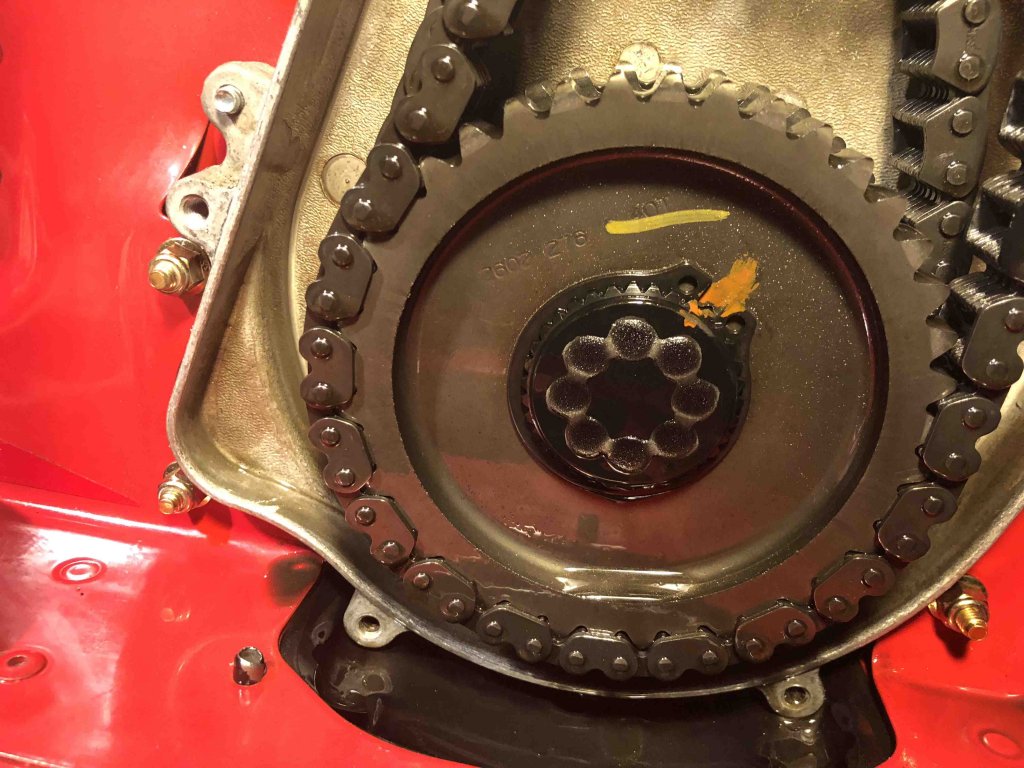

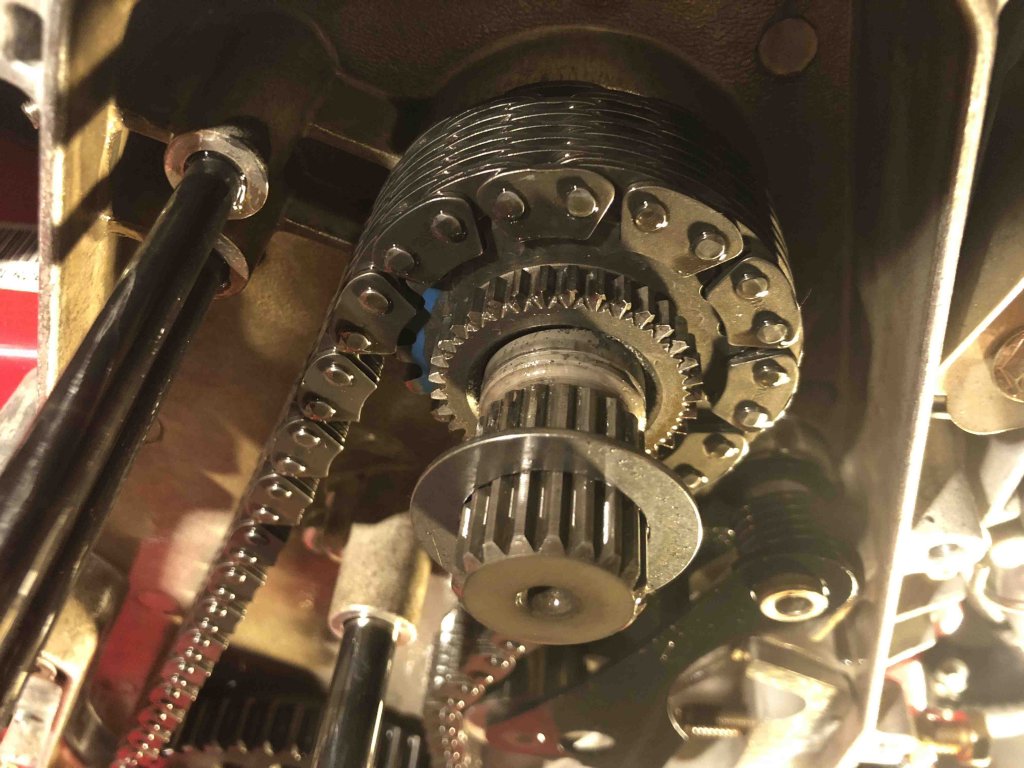

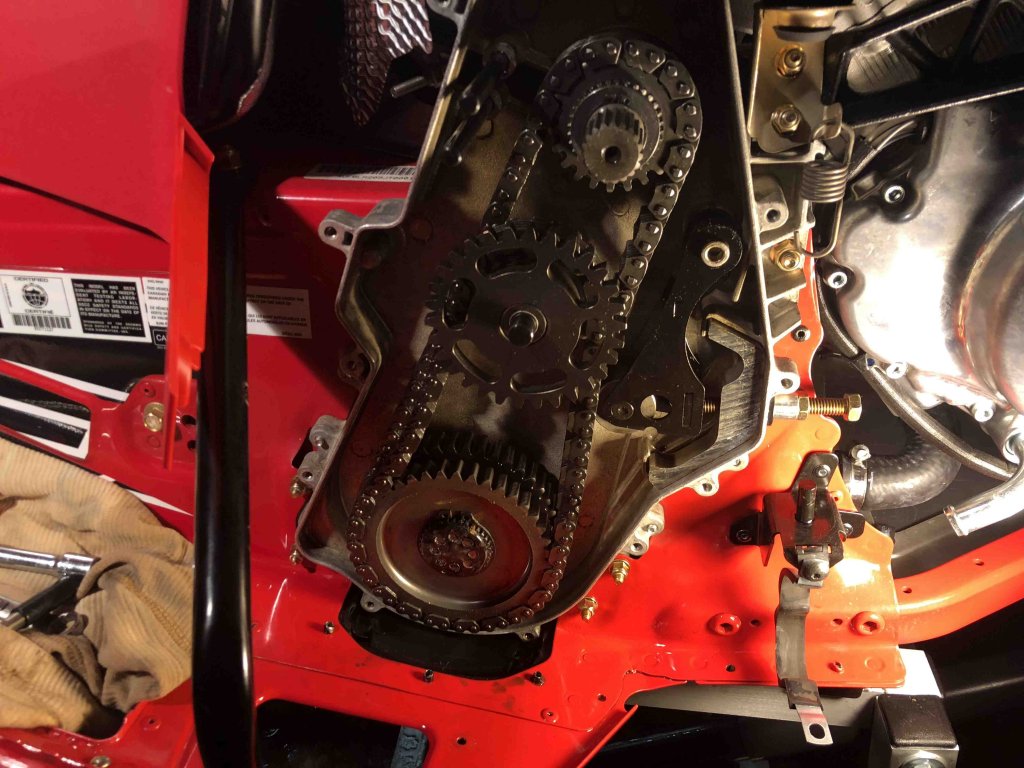

Part 3: Case opened

Cover should now pull straight off.

IMPORTANT: First thing to look for is one thrust washer that for me stuck to the cover, Its place is on the post outside of the center gear(not top or bottom). See Pic 3 below.

NOTE: Thrust washer as it stayed stuck to cover

Gasket/seal seems to be fine....

Notice the space between end of tensioner bolt & tensioner, 1.5 turns out.

Bottom drive shaft on the end, has a nice strong magnet here...Good work.

Removing the sliding gear and fork from top, this slides right off of the two posts.

Part 3: Case opened

Cover should now pull straight off.

IMPORTANT: First thing to look for is one thrust washer that for me stuck to the cover, Its place is on the post outside of the center gear(not top or bottom). See Pic 3 below.

NOTE: Thrust washer as it stayed stuck to cover

Gasket/seal seems to be fine....

Notice the space between end of tensioner bolt & tensioner, 1.5 turns out.

Bottom drive shaft on the end, has a nice strong magnet here...Good work.

Removing the sliding gear and fork from top, this slides right off of the two posts.

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Chaincase

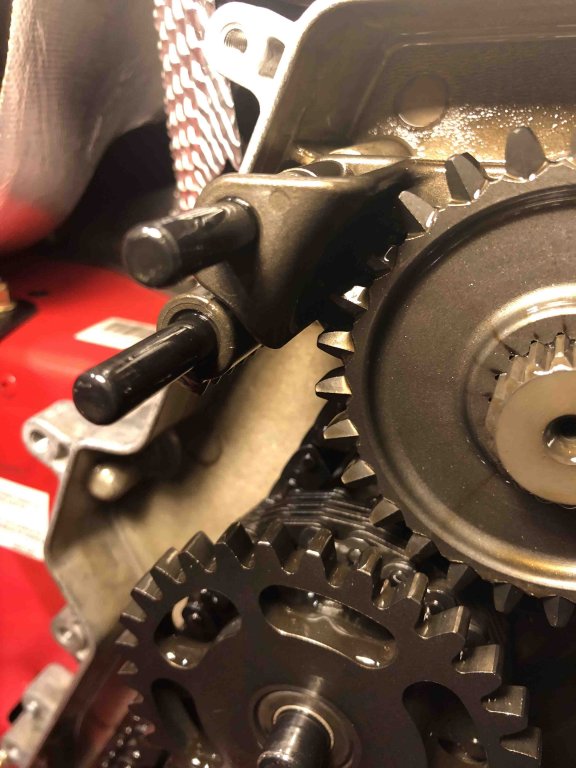

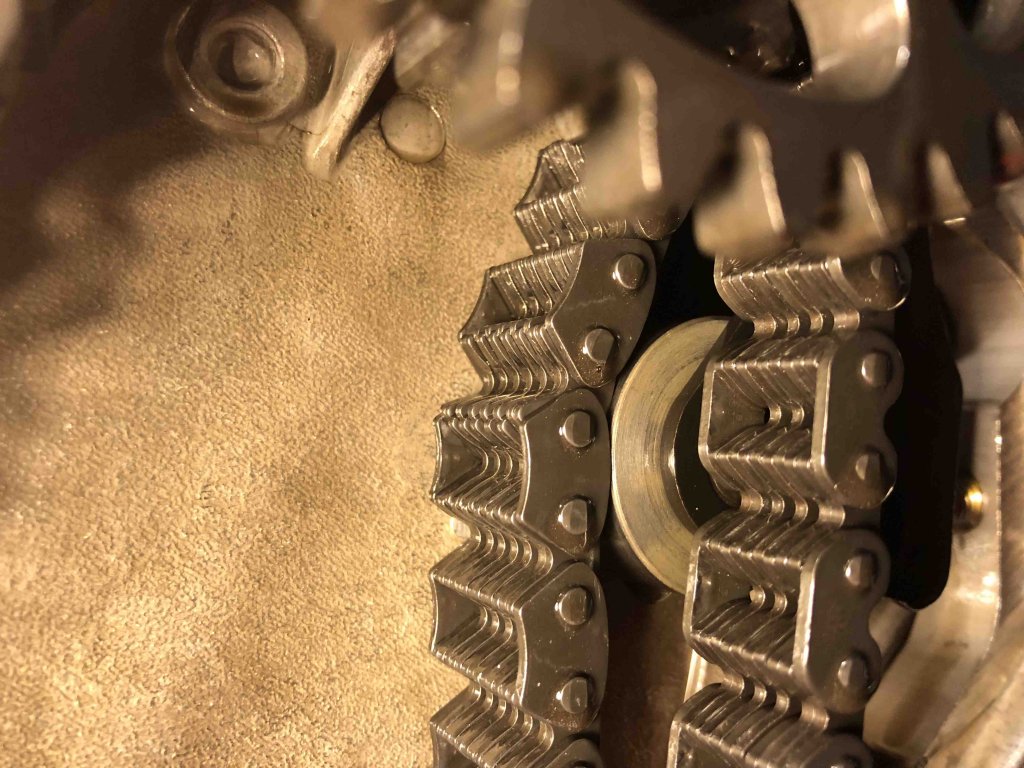

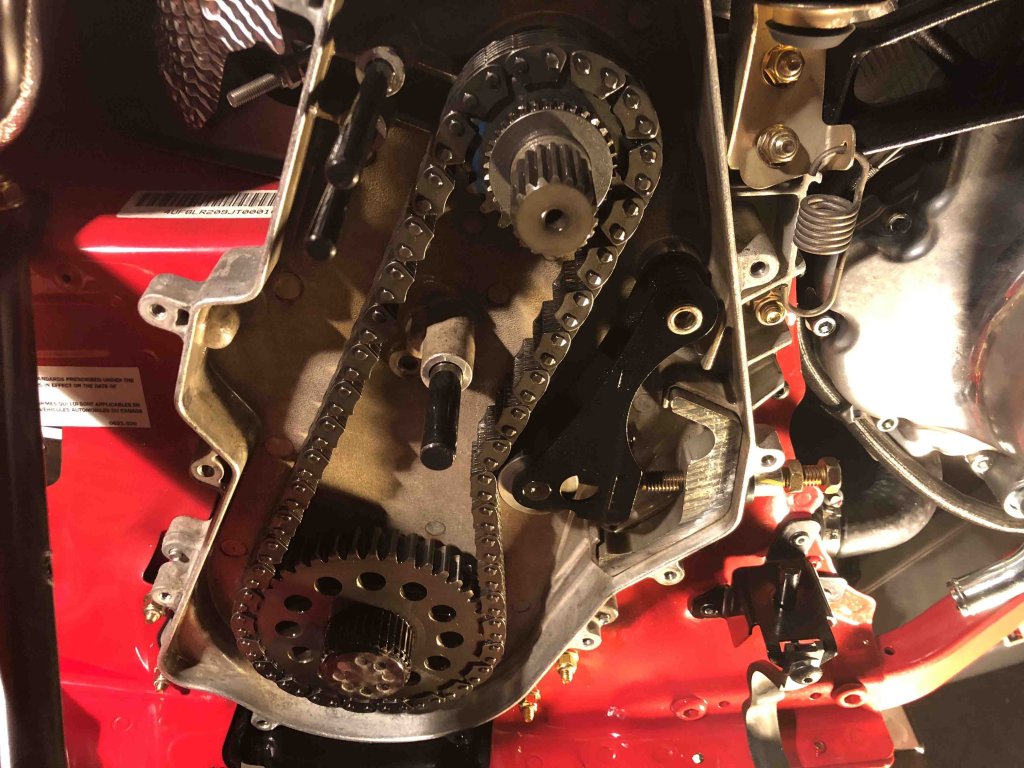

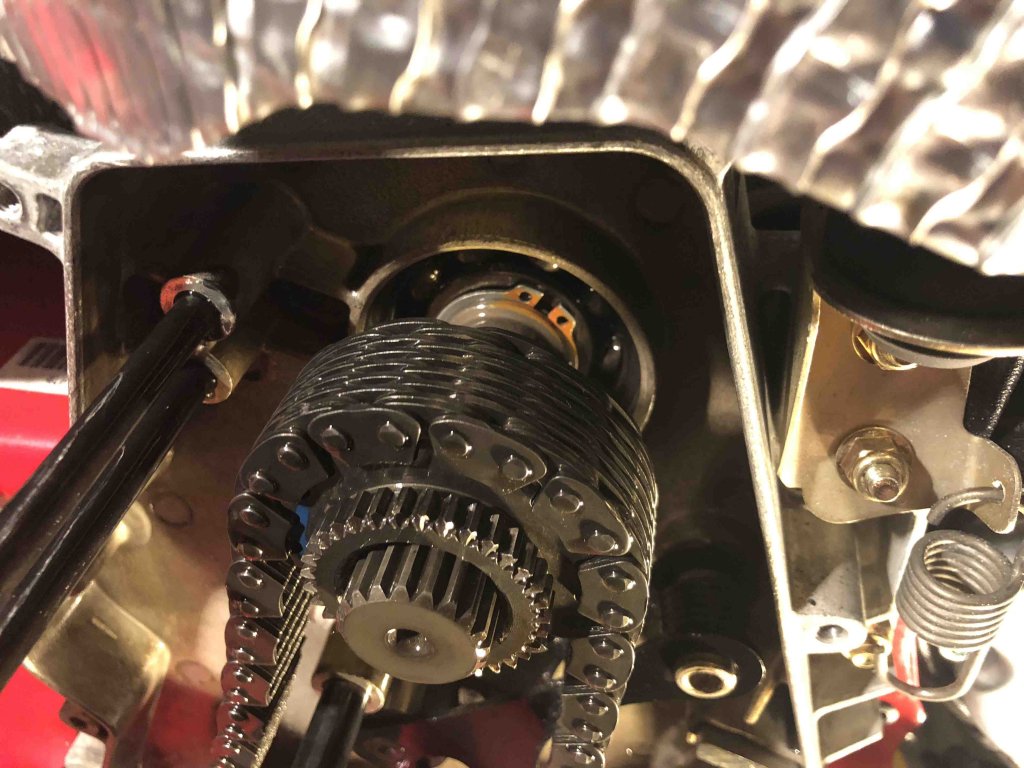

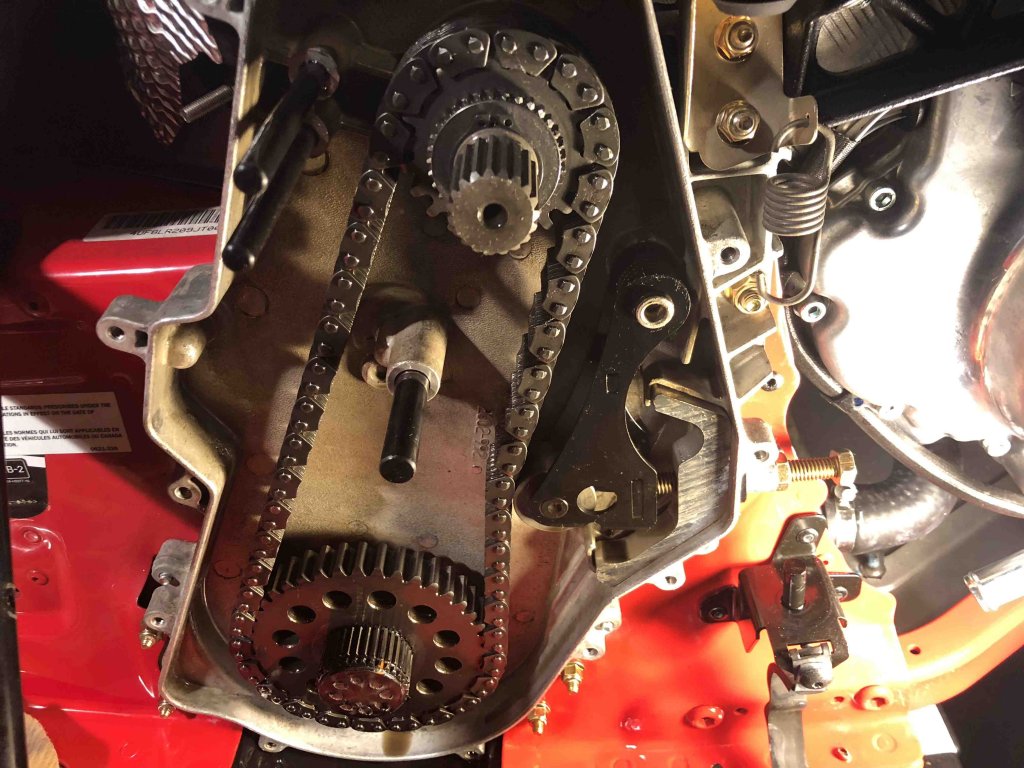

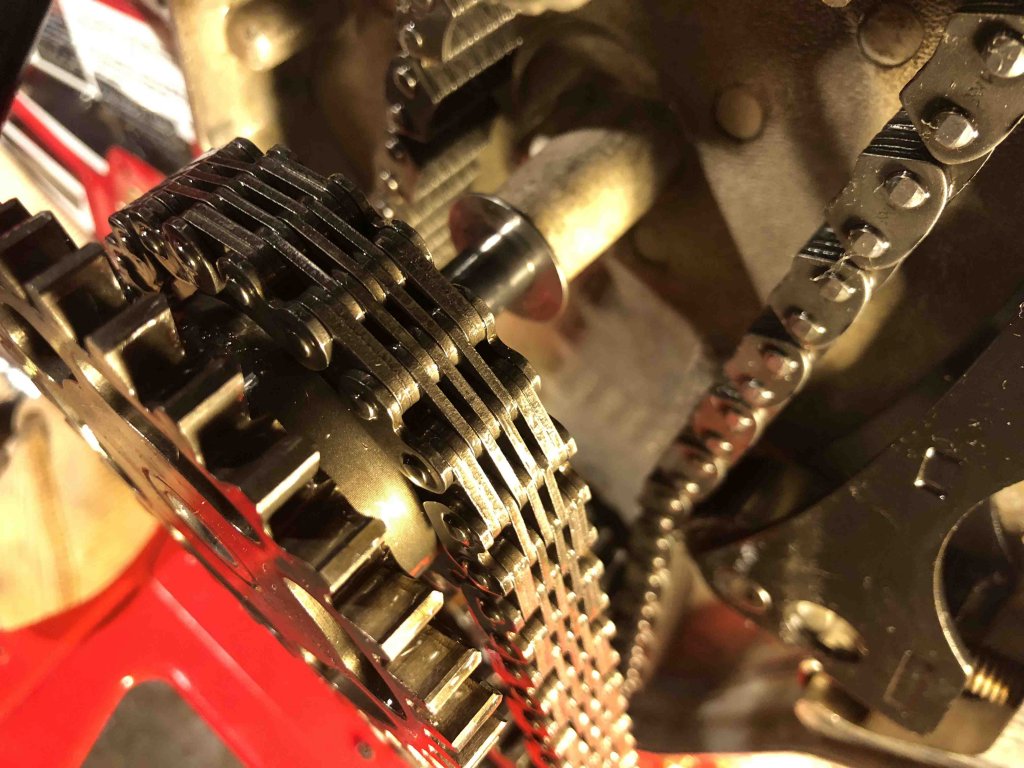

Part 4: Gears

Installing my 22 top gear, you must remove everything to do this.

Remove the bottom large circlip on drive axle. Then you can slide off the smaller reverse chain and reverse gears, set them aside all as it comes off. NOTE: There is a smaller thrust washer on backside of the center reverse gear post. Mine came off with the gear, so be sure you get that placement correct when going back together. There are two small thrust washers on each side of the center reverse gear(in front and behind)

Now you can remove the circlip on the top gear. There is a thrust washer on both sides(front and back) of the top drive gear.(stock is 21 tooth, im going up to 22 tooth)

Now you can slide off the entire drive chain and top/bottom gears altogether. Replace the 21 with 22. Be sure the thrust washer goes on backside of top gear when sliding it all back on with new 22 gear.

Remove large bottom drive axle circlip, then pull off reverse chain and gears.

After removing the reverse chain & gears(and smaller thrust washers -one in front of top reverse gear(center post) and one behind top reverse gear(center post), now we can remove the top gear circlip.

Notice the 'dogleg' is much greater with stock 21 gear then pic below with 22.

Stock top gear on 18 models have a hole drilled in them, but not through bushing.

Open seal on upper jackshaft bearing

Showing the two circlips on jackshaft, outward one holds place of top gear, thrust washer rides against this circlip

Showing the INNER thrust washer behind top gear

Open seal on lower main drive axle bearing

Slide on the main chain and gears altogther. Notice much less 'dogleg' in chain when using a 22 top gear.

Now install the reverse chain and gears, notice small thrust washer behind top reverse gear(center post). And don't forget the other thrust washer which stuck to the cover originally, this is same size and goes outside of the top reverse gear on this same post.(between gear and cover)

Install the large circlip, mine went on easy, but I have heard where you may need to pull tunnel together with ratchet strap to get circlip back into groove.

All gears back together, ready for cover. NOTE: In this pic i DO NOT show the small thrust washer that should be on top reverse gear(center post) between gear and cover, I obviously installed it but it is not in this pic. Also,this is a good time to do your chain tension, as you can do this by eye. I tried it to spec, and it was quite loose(1.5 turns out) so I went with 1 turn out which still looked abit loose, but I realize YAM wants some play here so it can mesh into reverse with less worry.

Closing up the chaincase

Cover goes back on, torque the black torx bolts to 12ft lbs, go easy on these as you dont want to strip anything. I started at 8 ft lbs which is all the DOO calls for. Be sure to clean off thread before installing them. Add good synthetic chain lube. Manual calls for 355ml or 12 oz.(UPDATE TO 16oz IMO--KLOTZ w/Graphite) and watch until you see it in center of sight glass,(TOP OF SIGHT GLASS WITH 16oz) filling it slowly not all at once as it comes up very slowly on sight glass. You will use a funnel to pour it into the hole where the reverse motor extension goes into backside of case.

Install the reverse motor extension as shown in pics above with detent facing down. TIP: When you first insert the extension, using the motor, try to rotate the extension CC(left) as much as possible, at this point you want the detent facing down. Then you can install the detent block and spring. Now check again, to be sure you cannot turn it CC anymore, and it sits in detent block at bottom correctly.(This is all in your manual).

Now install the motor(shift actuator) into the extension, and as shown in an earlier video, you want to be putting pressure toward the left(CC) when installing the 3 torx screws. The idea here is to always be sure the pressure is going CC, which slides that sliding fork left, and keeps it into FORWARD gear, and helps it to not slip into neutral.

Re-install all the wiring plugins, and do a few tests shifting it to be sure all is working properly.

Dan

Part 4: Gears

Installing my 22 top gear, you must remove everything to do this.

Remove the bottom large circlip on drive axle. Then you can slide off the smaller reverse chain and reverse gears, set them aside all as it comes off. NOTE: There is a smaller thrust washer on backside of the center reverse gear post. Mine came off with the gear, so be sure you get that placement correct when going back together. There are two small thrust washers on each side of the center reverse gear(in front and behind)

Now you can remove the circlip on the top gear. There is a thrust washer on both sides(front and back) of the top drive gear.(stock is 21 tooth, im going up to 22 tooth)

Now you can slide off the entire drive chain and top/bottom gears altogether. Replace the 21 with 22. Be sure the thrust washer goes on backside of top gear when sliding it all back on with new 22 gear.

Remove large bottom drive axle circlip, then pull off reverse chain and gears.

After removing the reverse chain & gears(and smaller thrust washers -one in front of top reverse gear(center post) and one behind top reverse gear(center post), now we can remove the top gear circlip.

Notice the 'dogleg' is much greater with stock 21 gear then pic below with 22.

Stock top gear on 18 models have a hole drilled in them, but not through bushing.

Open seal on upper jackshaft bearing

Showing the two circlips on jackshaft, outward one holds place of top gear, thrust washer rides against this circlip

Showing the INNER thrust washer behind top gear

Open seal on lower main drive axle bearing

Slide on the main chain and gears altogther. Notice much less 'dogleg' in chain when using a 22 top gear.

Now install the reverse chain and gears, notice small thrust washer behind top reverse gear(center post). And don't forget the other thrust washer which stuck to the cover originally, this is same size and goes outside of the top reverse gear on this same post.(between gear and cover)

Install the large circlip, mine went on easy, but I have heard where you may need to pull tunnel together with ratchet strap to get circlip back into groove.

All gears back together, ready for cover. NOTE: In this pic i DO NOT show the small thrust washer that should be on top reverse gear(center post) between gear and cover, I obviously installed it but it is not in this pic. Also,this is a good time to do your chain tension, as you can do this by eye. I tried it to spec, and it was quite loose(1.5 turns out) so I went with 1 turn out which still looked abit loose, but I realize YAM wants some play here so it can mesh into reverse with less worry.

Closing up the chaincase

Cover goes back on, torque the black torx bolts to 12ft lbs, go easy on these as you dont want to strip anything. I started at 8 ft lbs which is all the DOO calls for. Be sure to clean off thread before installing them. Add good synthetic chain lube. Manual calls for 355ml or 12 oz.(UPDATE TO 16oz IMO--KLOTZ w/Graphite) and watch until you see it in center of sight glass,(TOP OF SIGHT GLASS WITH 16oz) filling it slowly not all at once as it comes up very slowly on sight glass. You will use a funnel to pour it into the hole where the reverse motor extension goes into backside of case.

Install the reverse motor extension as shown in pics above with detent facing down. TIP: When you first insert the extension, using the motor, try to rotate the extension CC(left) as much as possible, at this point you want the detent facing down. Then you can install the detent block and spring. Now check again, to be sure you cannot turn it CC anymore, and it sits in detent block at bottom correctly.(This is all in your manual).

Now install the motor(shift actuator) into the extension, and as shown in an earlier video, you want to be putting pressure toward the left(CC) when installing the 3 torx screws. The idea here is to always be sure the pressure is going CC, which slides that sliding fork left, and keeps it into FORWARD gear, and helps it to not slip into neutral.

Re-install all the wiring plugins, and do a few tests shifting it to be sure all is working properly.

Dan

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Rollover Valve Removal

With the ultra cold temps early this winter, we saw some issues with the rollover valve freezing up, and in turn could cause too much pressure in the OIL tank. And eventually we saw plenty of sleds(more 17s then 18s) with seeping oil tanks. The oil tank is sealed to the chaincase cover with silicone, and so apparently once too much pressure builds the silicone seal cannot hold it back and it starts to push oil. Not good.

A secondary thing many of us dont like, is even when the rollover valve works as designed, it blows the oil vapors back into the intake tract, which in turn ends up in your charge tubes. Not good either IMO.

A simple/easy solution to both of these problems is deleting it altogether. This is not something everyone should do. If your sled is rolled over, oil MAY be lost, and who knows what else can go wrong, so this should be done with extreme care/caution. Nuff said about that.

Just a few pics and a short vid.....should explain it all.

Dan

Be sure to use fuel line(NOT HEATER HOSE) as it will sweat oil eventually thru heater hose.

With the ultra cold temps early this winter, we saw some issues with the rollover valve freezing up, and in turn could cause too much pressure in the OIL tank. And eventually we saw plenty of sleds(more 17s then 18s) with seeping oil tanks. The oil tank is sealed to the chaincase cover with silicone, and so apparently once too much pressure builds the silicone seal cannot hold it back and it starts to push oil. Not good.

A secondary thing many of us dont like, is even when the rollover valve works as designed, it blows the oil vapors back into the intake tract, which in turn ends up in your charge tubes. Not good either IMO.

A simple/easy solution to both of these problems is deleting it altogether. This is not something everyone should do. If your sled is rolled over, oil MAY be lost, and who knows what else can go wrong, so this should be done with extreme care/caution. Nuff said about that.

Just a few pics and a short vid.....should explain it all.

Dan

Be sure to use fuel line(NOT HEATER HOSE) as it will sweat oil eventually thru heater hose.

Last edited:

Blueaway

Lifetime Member

- Joined

- Nov 16, 2016

- Messages

- 111

- Reaction score

- 35

- Points

- 483

- Location

- Alliston

- Country

- Canada

- Snowmobile

- 2023 srx

Thank you very much for that Dan.. You sure know these sleds .

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Aiming Headlight

I wanted my headlight abit higher, the adjuster is much better then my old 12 cat was. Using a small 4mm socket and extension you can adjust it. Its located just inside the hood, above the shelf.

Turn it CC to raise headlight, and Clockwise to lower headlight.

Dan

I wanted my headlight abit higher, the adjuster is much better then my old 12 cat was. Using a small 4mm socket and extension you can adjust it. Its located just inside the hood, above the shelf.

Turn it CC to raise headlight, and Clockwise to lower headlight.

Dan

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,610

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

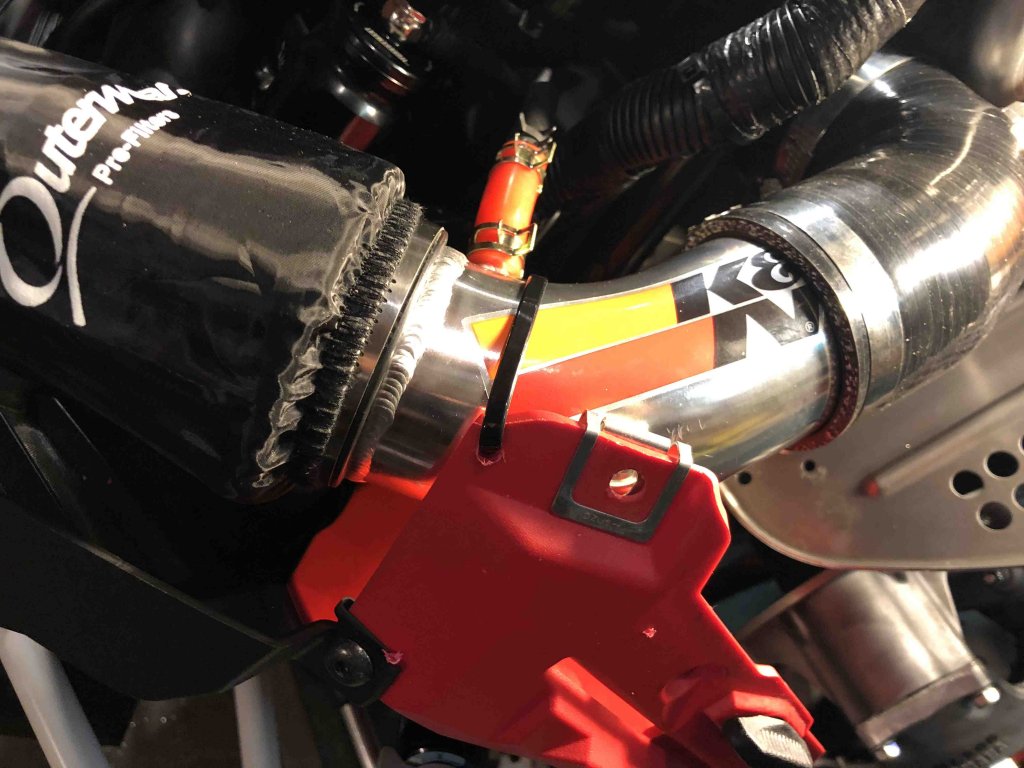

Cold Air Intake Installed(CAI)- Finished(Part 3)

Its time for all the goodies!

Since I got on my 550 stock miles, I got to do my oil change, and since I had to remove muffler to get into chaincase, it all made sense to do the 22 top gear, muffler, and TUNE, which meant it was time for my own CAI to go on.

I mocked up my design back on the fall, which is earlier on in this thread(All quick jump links are on post #1). I decided to get a screw on nipple for the rear vent hose that comes over from valve cover, it worked out very nicely.

This design has a massive amount of airflow UNDER the CAI, to blow directly on clutches and belt. This more then anything is quite impressive, to have such direct flow will surely take alot of temp off the clutches. The design with a slight bend in tube in addition to the silicone elbow, allows for twisting the CAI into place very high.

A modest sized k&n air filter also allows for more air flow through the stock screen/vent, and down to the clutches/belt.

The next thing I did was to zip tie the final placement, to the side panel. This will stop it from any movement when pounding through the junk. I have not seen other kits have any type of help holding it up, but I wanted to be sure this stays put and does not wear anywhere. I also installed my Outerwears filter sock.

Upon firing it up.....I was blown away how INSTANT the throttle feels compared to before, just on the stand. Im dying to take this baby for a ride now!

-K&N Part# SN-2570

-Outerwears filter sock - #20-1469

Dan

LINK for barbed Vent inserts: https://www.viperperformance.co.uk/...103_self-seal-take-offfor-silicone-hoses.html

Its time for all the goodies!

Since I got on my 550 stock miles, I got to do my oil change, and since I had to remove muffler to get into chaincase, it all made sense to do the 22 top gear, muffler, and TUNE, which meant it was time for my own CAI to go on.

I mocked up my design back on the fall, which is earlier on in this thread(All quick jump links are on post #1). I decided to get a screw on nipple for the rear vent hose that comes over from valve cover, it worked out very nicely.

This design has a massive amount of airflow UNDER the CAI, to blow directly on clutches and belt. This more then anything is quite impressive, to have such direct flow will surely take alot of temp off the clutches. The design with a slight bend in tube in addition to the silicone elbow, allows for twisting the CAI into place very high.

A modest sized k&n air filter also allows for more air flow through the stock screen/vent, and down to the clutches/belt.

The next thing I did was to zip tie the final placement, to the side panel. This will stop it from any movement when pounding through the junk. I have not seen other kits have any type of help holding it up, but I wanted to be sure this stays put and does not wear anywhere. I also installed my Outerwears filter sock.

Upon firing it up.....I was blown away how INSTANT the throttle feels compared to before, just on the stand. Im dying to take this baby for a ride now!

-K&N Part# SN-2570

-Outerwears filter sock - #20-1469

Dan

LINK for barbed Vent inserts: https://www.viperperformance.co.uk/...103_self-seal-take-offfor-silicone-hoses.html

Last edited:

Soldier'spapa

Lifetime Member

- Joined

- Mar 21, 2006

- Messages

- 729

- Reaction score

- 118

- Points

- 908

- Location

- Naperville, IL

- Country

- USA

- Snowmobile

- 2018 Sidewinder Ltx LE 50th Anniversary

First Oil Change - Oil Tank

Part 2: Draining the Oil tank:

Now that engine block is drained and buttoned up, we can move to the oil tank. With my lower side panel removed, Its very easy to remove the main drain bolt on bottom of oil tank. No funnel needed.

View attachment 135944

View attachment 135945

View attachment 135951

View attachment 135952

I reused my o-ring which stayed right onto the drain plug.

View attachment 135946

Once most of tank is drained from the bottom tank plug, I decided I would get ALL the oil out. There are two hoses/tubes right there, that will hold oil in them even after draining block and tank. With lower side panel removed, its simple to now drain these two hoses. This will allow for a 100% complete oil draining of the sled, and IMO should be done.

Drain these hoses/tubes below - See Videos

View attachment 135947

Once all oil is drained from tank and hoses/tubes....reinstall the plug and hoses/tubes. And pour in 3Qts full synthetic mobil 1 5w30(IMO). Start engine(be sure you have everything back together before starting engine) and watch oil light to be sure it goes out within 10 seconds. If all is good with light, check level on tank gauge. With mine it was VERY LOW(stopped engine quickly) as I was able to remove much more oil then if I had not removed tubes/hoses. So i added more oil right away, getting it closer to BOTTOM level line. Then I re-started engine and allowed a full warm up(Oil level will RAISE as engine temp comes up). After fully warm I topped off oil level to the TOP level line(WARM ENGINE)

View attachment 135948

View attachment 135949[/QUOTE

Dan, Fantastic work documenting these procedures for us all to reference! I appreciate it very much!

Quick question for you... is there a screen on the oil tank elbow that needs to be cleaned at first oil change? My Apex and Phazer had one that caught shavings during engine break in.

allyammies

VIP Member

Nice Dan used your Apex build thread many times will be using this too. Thanks for a great thread.

Similar threads

- Replies

- 42

- Views

- 15K

- Replies

- 7

- Views

- 33K

- Replies

- 74

- Views

- 13K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.