ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Greasing the Driveshaft Bearing(Under brake rotor)

This job is one of those maintenance things that should be done seasonally, or at least every other season. Normally I did my apex bearing grease every fall, and it always looked bad. Rust built up inside and grease was dried out.

Now on the Winder, after season one and approx 1450 miles, the bearing actually looked great. Grease was not dried out and no rust that I could see whatsoever. This may be due to the design. There is a cover/seal under the tunnel, and a good space between that seal and where the bearing sits on the driveshaft. So this surely must be helping to keep snow/moisture away from bearing seal.

It has been reported that these bearings may end up spinning on the shaft. We have seen this several times, and then the bearing eats into the driveshaft and now the shaft it junk. So greasing the bearing once every season will go a long way to keeping it spinning freely. If it gets rusty that is when it will want to spin on shaft. I also dimpled the seat where bearing sits on shaft, using a carbide stud, since a normal steel punch wont be hard enough, It worked well!

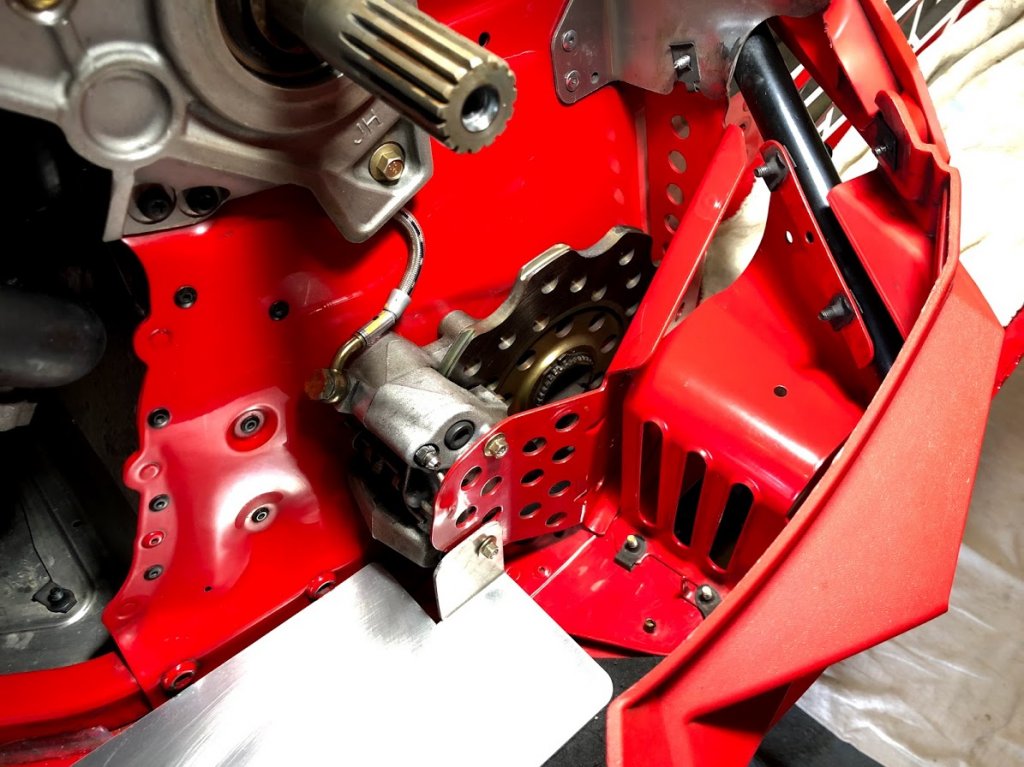

To do this job, skid needs to come out......This takes pressure off the shaft. There are 3 bolts that go from under the tunnel into the caliper/bracket. The caliper/bracket houses the bearing. So we need to slide the brake rotor AND caliper(altogether) off the driveshaft all at once, then once off the shaft, we can remove the rotor from Caliper, and that will expose the bearing.

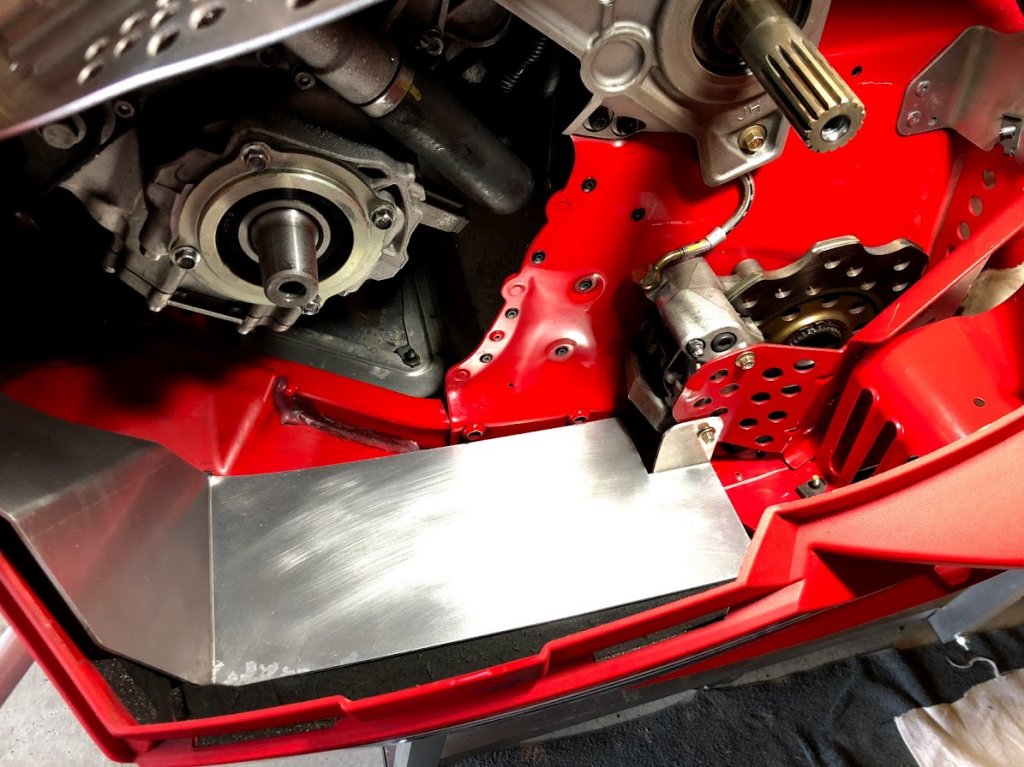

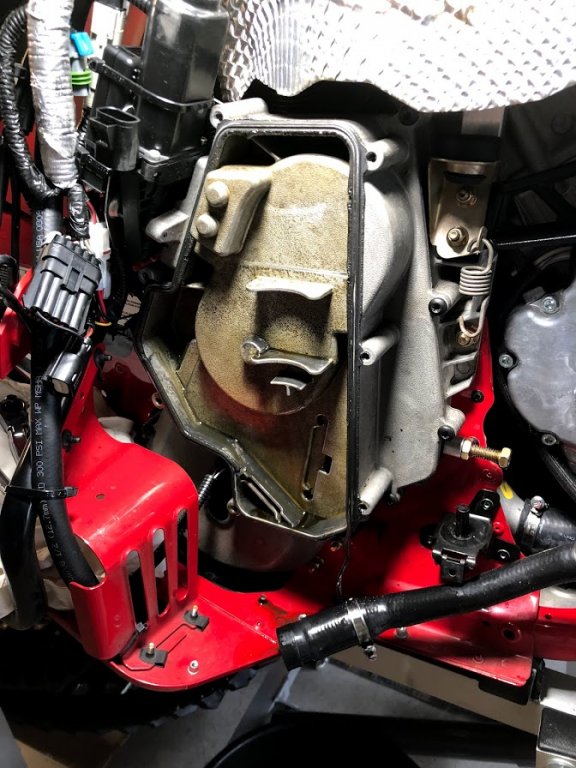

Once skid is out, start by removing the footwell and brake rotor covers on left side....Its easier access if you remove the secondary clutch.

I have several videos going along as I did this job today....Here is the first one.

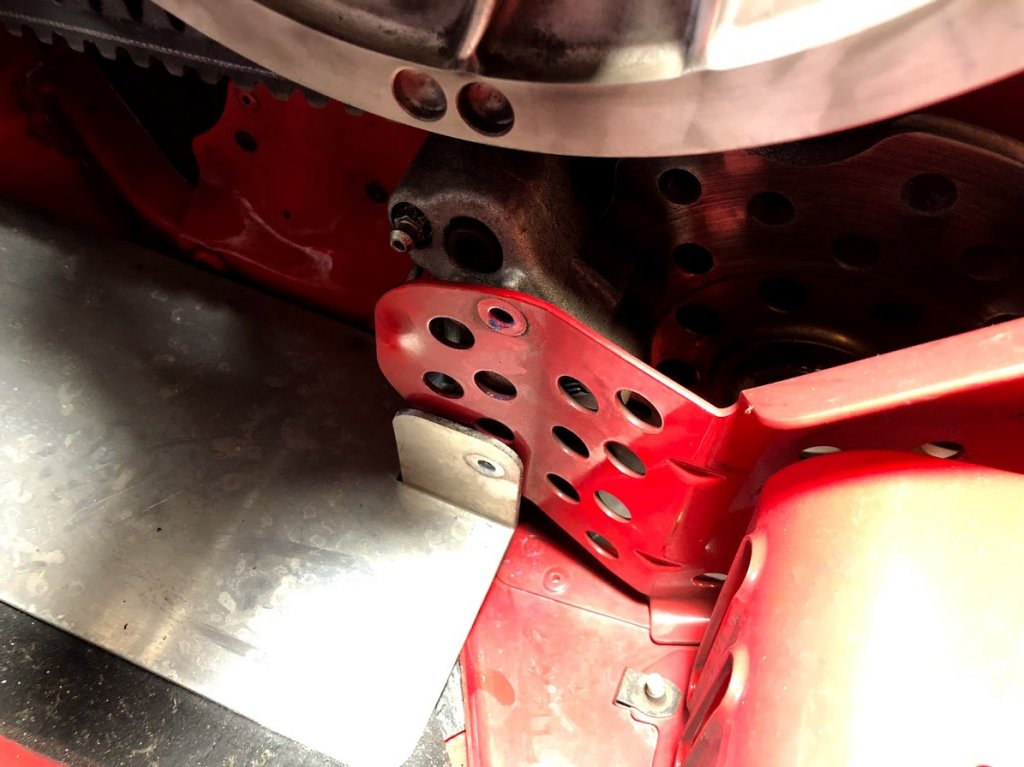

The Barn of parts bellypan protector needs to be removed too.....

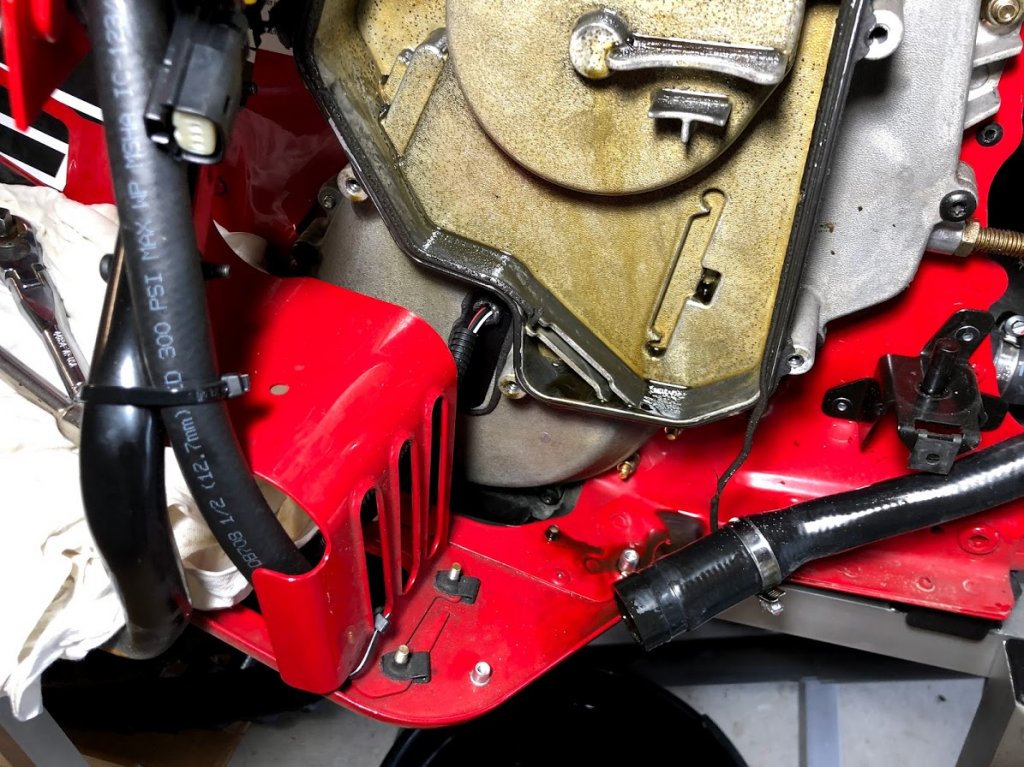

3 bolts from under tunnel, need to be loosened off

10mm socket

This job is one of those maintenance things that should be done seasonally, or at least every other season. Normally I did my apex bearing grease every fall, and it always looked bad. Rust built up inside and grease was dried out.

Now on the Winder, after season one and approx 1450 miles, the bearing actually looked great. Grease was not dried out and no rust that I could see whatsoever. This may be due to the design. There is a cover/seal under the tunnel, and a good space between that seal and where the bearing sits on the driveshaft. So this surely must be helping to keep snow/moisture away from bearing seal.

It has been reported that these bearings may end up spinning on the shaft. We have seen this several times, and then the bearing eats into the driveshaft and now the shaft it junk. So greasing the bearing once every season will go a long way to keeping it spinning freely. If it gets rusty that is when it will want to spin on shaft. I also dimpled the seat where bearing sits on shaft, using a carbide stud, since a normal steel punch wont be hard enough, It worked well!

To do this job, skid needs to come out......This takes pressure off the shaft. There are 3 bolts that go from under the tunnel into the caliper/bracket. The caliper/bracket houses the bearing. So we need to slide the brake rotor AND caliper(altogether) off the driveshaft all at once, then once off the shaft, we can remove the rotor from Caliper, and that will expose the bearing.

Once skid is out, start by removing the footwell and brake rotor covers on left side....Its easier access if you remove the secondary clutch.

I have several videos going along as I did this job today....Here is the first one.

The Barn of parts bellypan protector needs to be removed too.....

3 bolts from under tunnel, need to be loosened off

10mm socket

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Greasing the driveshaft bearing cont.

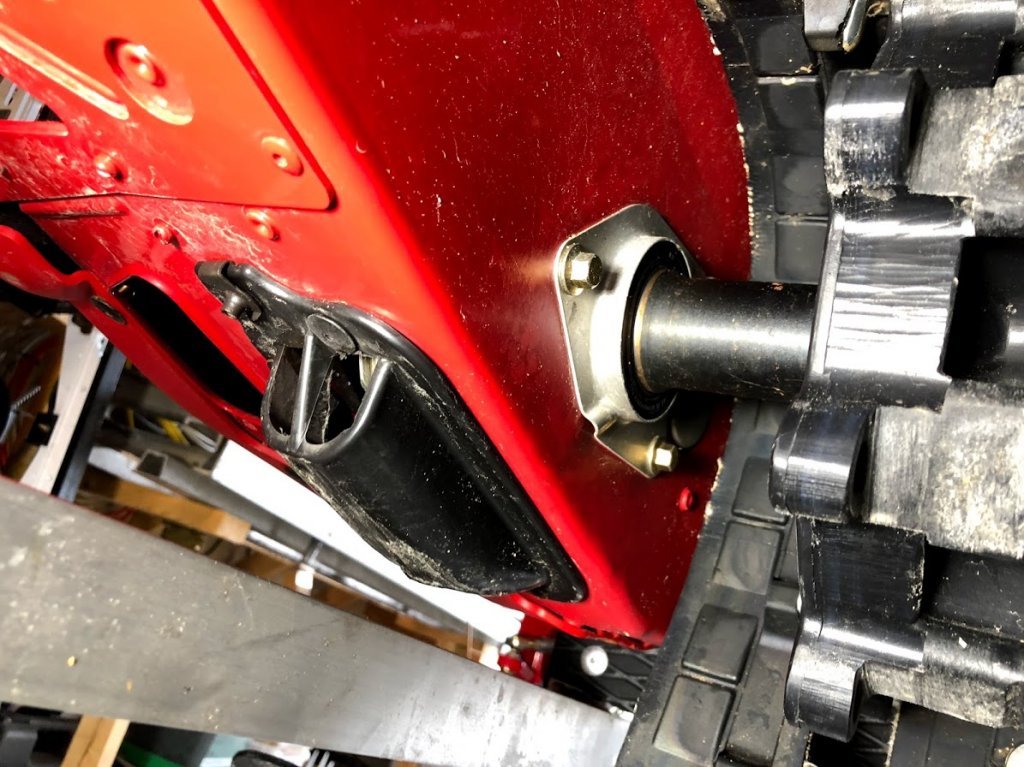

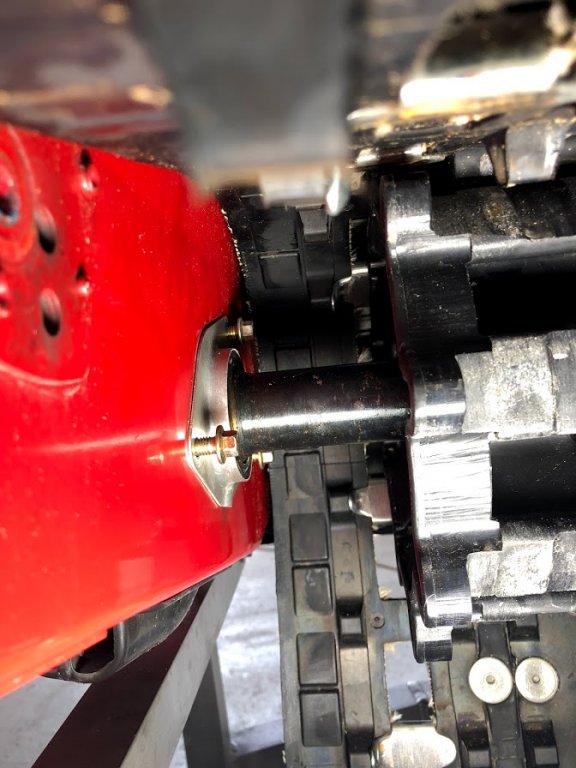

With the 3 Bolts from under tunnel loosened off, remove the circlip from shaft.

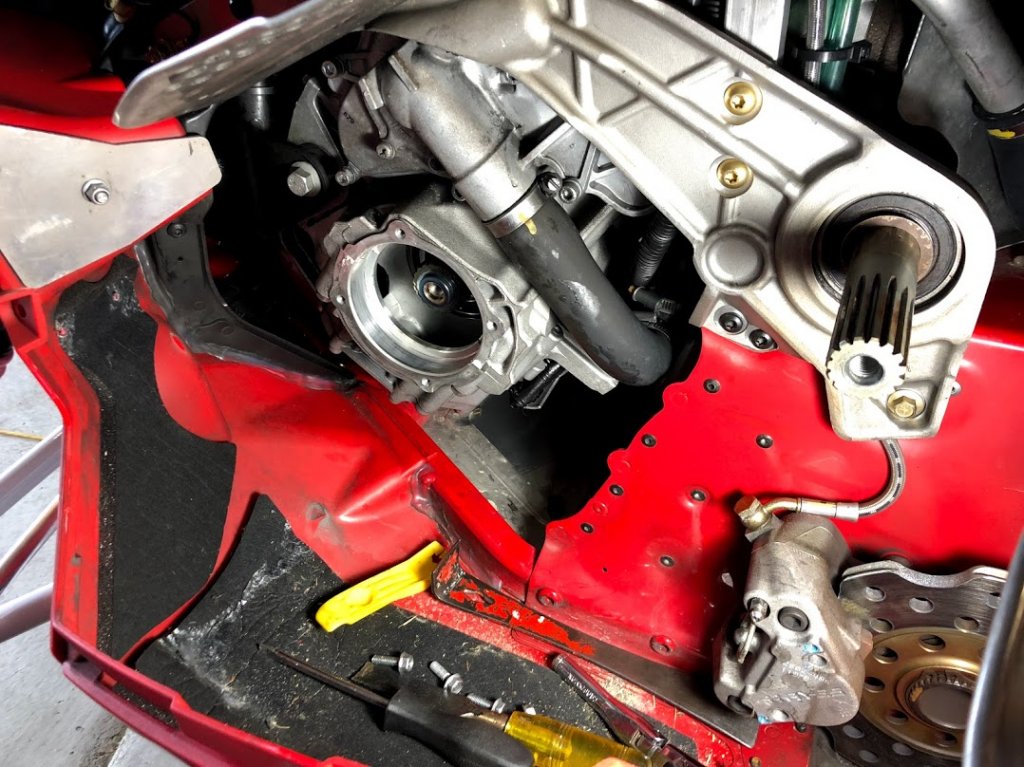

Now remove 3 bolts entirely, and start to wiggle the caliper and rotor(altogether) off the end of the splined driveshaft. You may need to cut a zip tie on brake line up near top of fuel tank under hood,left side.

Angle it off the end(tight brake line).....while lifting up on driveshaft, and it will come off at an angle....I reinstalled 2 bolts back thru from tunnel thru the inside tunnel plate into tunnel, to help support the shaft while caliper/bracket is removed.

Video...

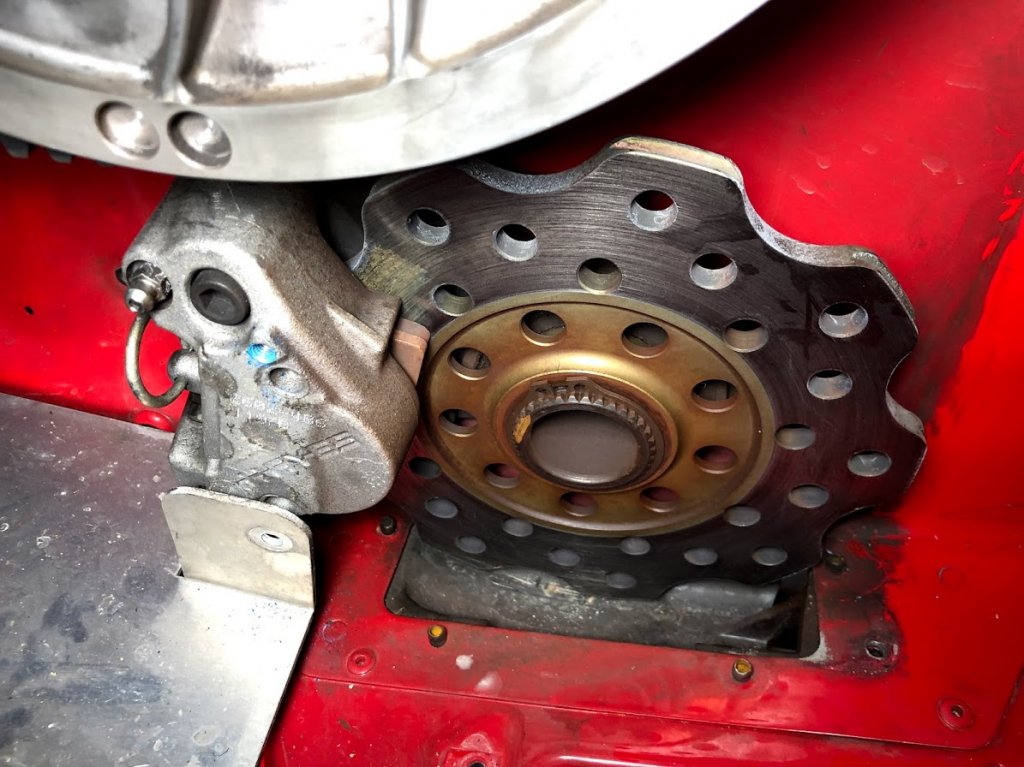

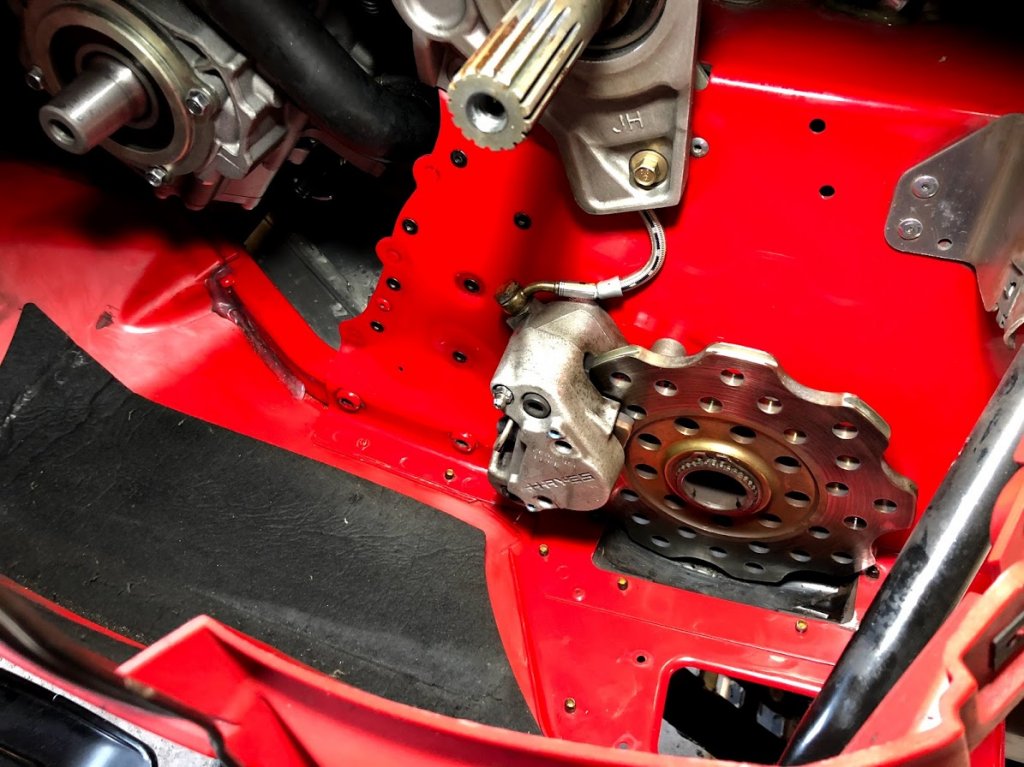

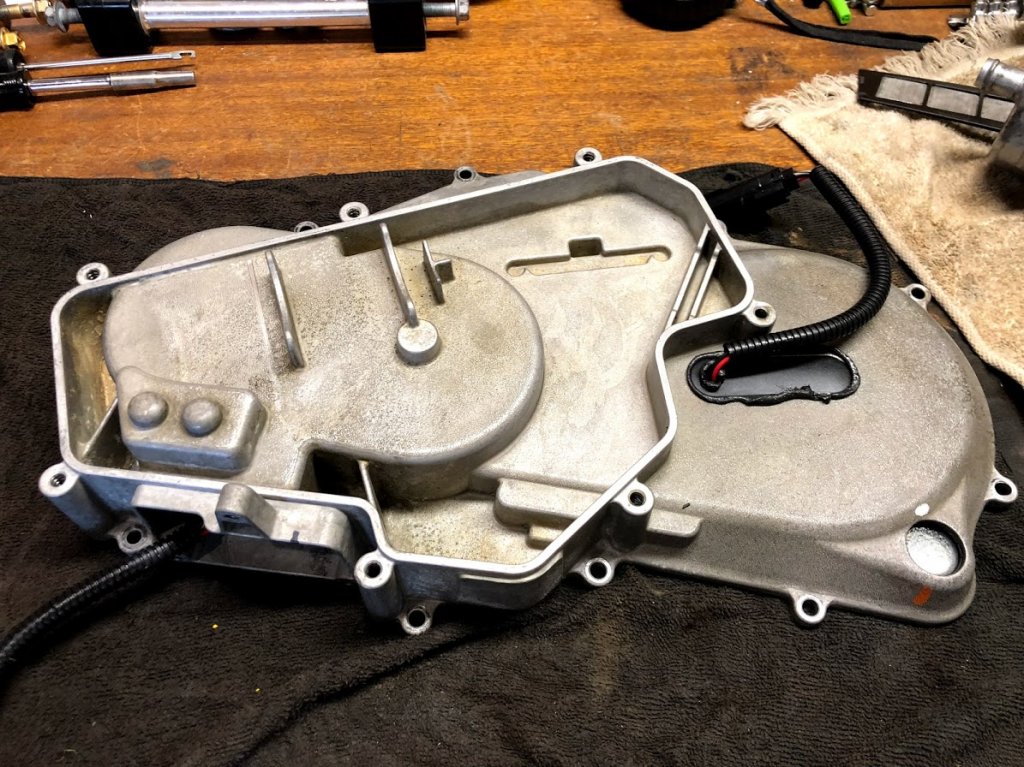

Exposed shaft with caliper removed

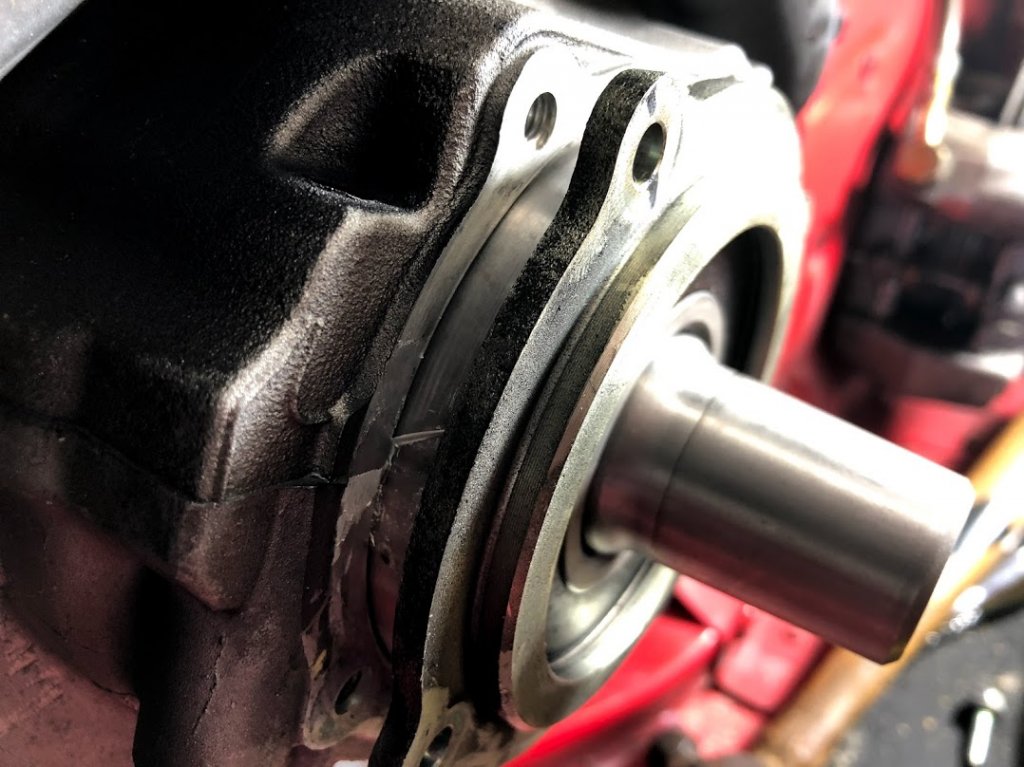

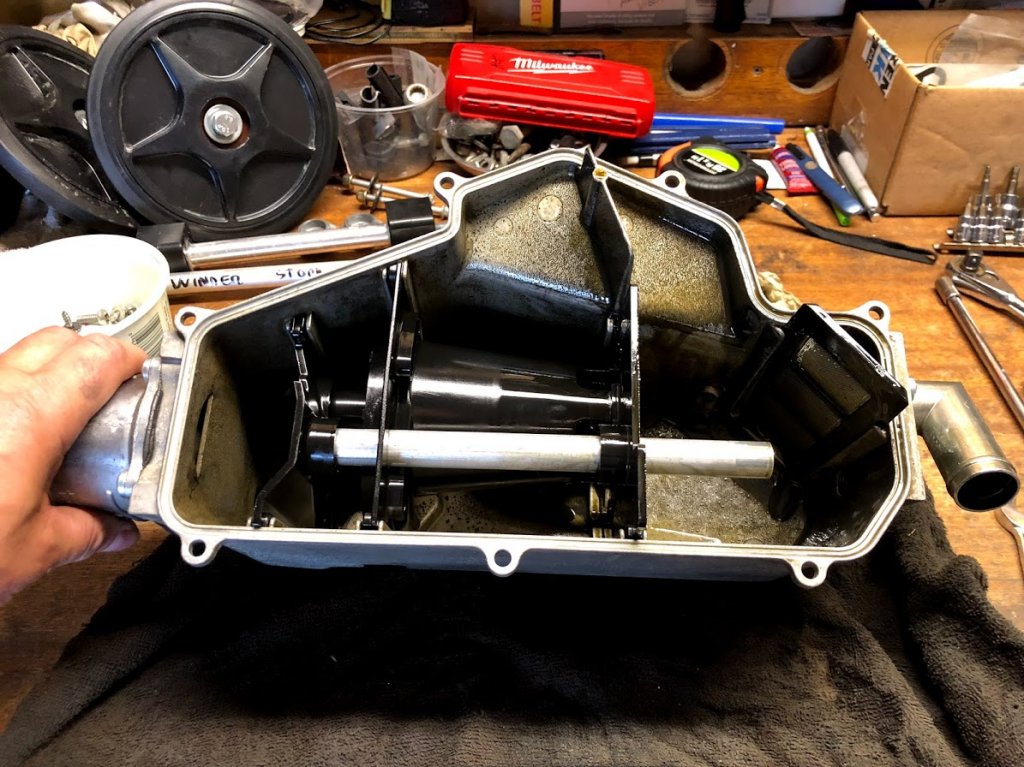

Once off the shaft, slide rotor out of the brake pads, and out from caliper.....Exposing bearing.

Notice the 2 bolts from tunnel plate through tunnel, temporarily helping to hold up shaft. Letting it hang can be stressful on the chaincase side bearing ect.

VIDEO:

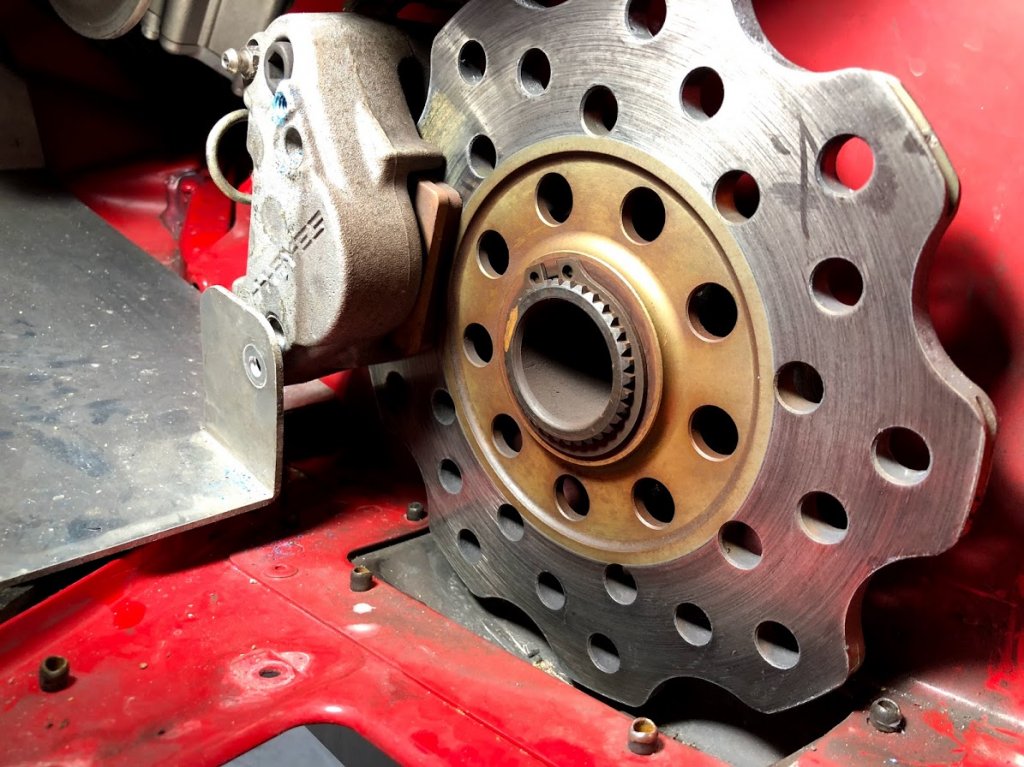

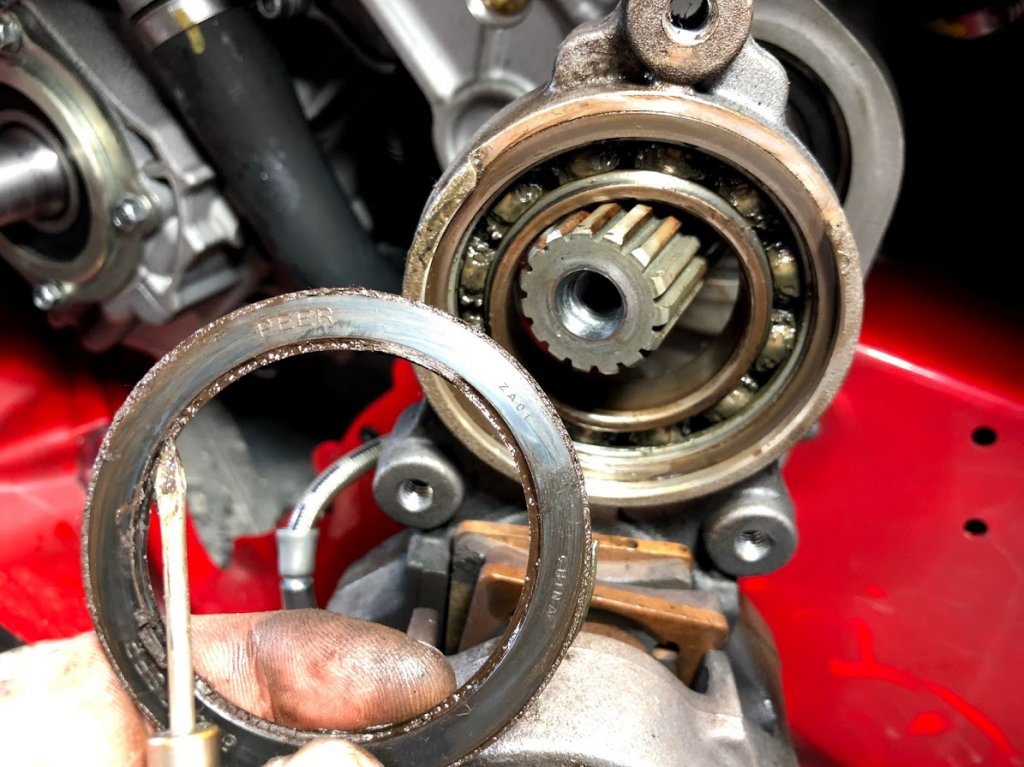

Backside of bearing seated in caliper bracket.

I set the bearing onto the Jackshaft to work on it.....Used a tiny flat screwdriver to pop off bearing cap.

comes off easily....

Now clean/spray out the bearing to clean it out(wd40 works)

VIDEO:

Used a Gold digger carbide stud, to "dimple" the shaft where bearing seats. To help give it bite to prevent race from spinning on shaft, an issue that has been reported on these sleds.

I tapped(hammered) in 4 dimples(12, 3, 6, 9- o'clock)

VIDEO:

With the 3 Bolts from under tunnel loosened off, remove the circlip from shaft.

Now remove 3 bolts entirely, and start to wiggle the caliper and rotor(altogether) off the end of the splined driveshaft. You may need to cut a zip tie on brake line up near top of fuel tank under hood,left side.

Angle it off the end(tight brake line).....while lifting up on driveshaft, and it will come off at an angle....I reinstalled 2 bolts back thru from tunnel thru the inside tunnel plate into tunnel, to help support the shaft while caliper/bracket is removed.

Video...

Exposed shaft with caliper removed

Once off the shaft, slide rotor out of the brake pads, and out from caliper.....Exposing bearing.

Notice the 2 bolts from tunnel plate through tunnel, temporarily helping to hold up shaft. Letting it hang can be stressful on the chaincase side bearing ect.

VIDEO:

Backside of bearing seated in caliper bracket.

I set the bearing onto the Jackshaft to work on it.....Used a tiny flat screwdriver to pop off bearing cap.

comes off easily....

Now clean/spray out the bearing to clean it out(wd40 works)

VIDEO:

Used a Gold digger carbide stud, to "dimple" the shaft where bearing seats. To help give it bite to prevent race from spinning on shaft, an issue that has been reported on these sleds.

I tapped(hammered) in 4 dimples(12, 3, 6, 9- o'clock)

VIDEO:

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Greasing the driveshaft bearing cont....

Now with the bearing all cleaned out, repack the bearing with new grease....

Push cap back on with your fingers, pops right in easily.

Clean off excess grease.... I then took some brake cleaner on a paper towel, and wiped down the shaft where bearing seats(where I put the dimples), and also wiped down inside of inner race on bearing, we don't want any grease on these two surfaces where bearing seats, as we are trying to prevent race from spinning on shaft.

VIDEO:

Now reverse your order, slide rotor back in between brake pads, angle rotor/caliper back into lower pocket and onto end of driveshaft. Mine slipped on easily. Now hold up on drive shaft and get your 3 bolts started from underneath, and tighten them each alittle at time drawing in the bearing/caliper onto the seat of driveshaft. Keep them equal so it goes on straight. Tighten them up. Some guys will have to use ratchet strap to draw tunnel together if your circlip does not go on, but I was able to pull brake lever which tightened up brake pads, and then tapped on rotor a couple times with small hammer and it went right back into place exposing the groove, and then I was able to install circlip without any strap. Went very well!

all back together...Be sure to use loctite on the footwell bracket and rotor bracket bolts...Reinstall BOP belly protector.

Now with the bearing all cleaned out, repack the bearing with new grease....

Push cap back on with your fingers, pops right in easily.

Clean off excess grease.... I then took some brake cleaner on a paper towel, and wiped down the shaft where bearing seats(where I put the dimples), and also wiped down inside of inner race on bearing, we don't want any grease on these two surfaces where bearing seats, as we are trying to prevent race from spinning on shaft.

VIDEO:

Now reverse your order, slide rotor back in between brake pads, angle rotor/caliper back into lower pocket and onto end of driveshaft. Mine slipped on easily. Now hold up on drive shaft and get your 3 bolts started from underneath, and tighten them each alittle at time drawing in the bearing/caliper onto the seat of driveshaft. Keep them equal so it goes on straight. Tighten them up. Some guys will have to use ratchet strap to draw tunnel together if your circlip does not go on, but I was able to pull brake lever which tightened up brake pads, and then tapped on rotor a couple times with small hammer and it went right back into place exposing the groove, and then I was able to install circlip without any strap. Went very well!

all back together...Be sure to use loctite on the footwell bracket and rotor bracket bolts...Reinstall BOP belly protector.

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Overview Video of greasing the driveshaft bearing

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Stub Shaft removal

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

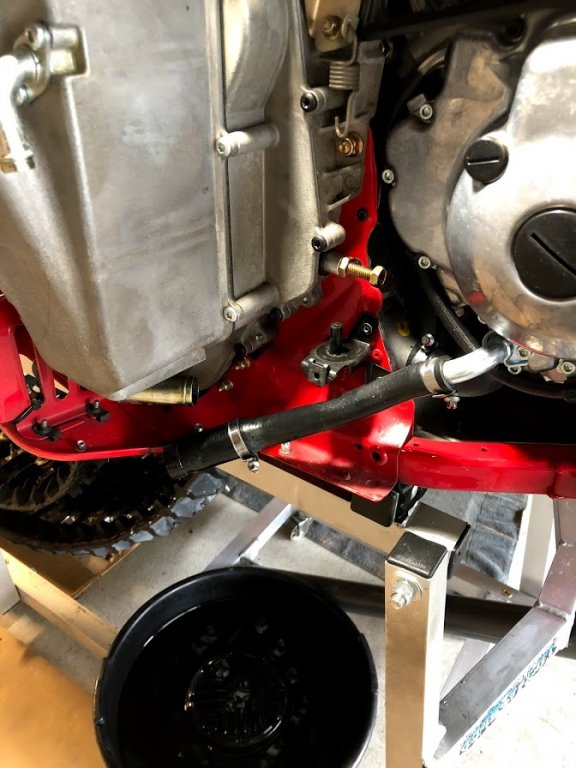

Oil Tank seal repair

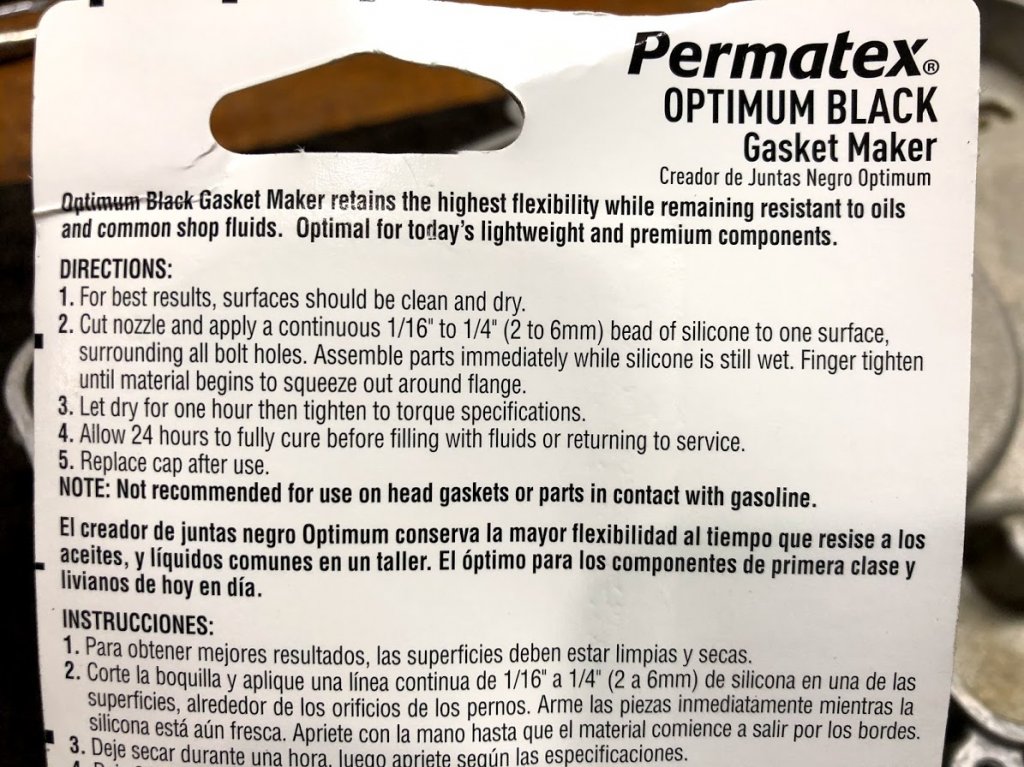

Most all these oil tanks tend to leak/seep eventually. The key is to get them drained and dry/clean to make a good seal with new Silicone RTV. I went with Permatex Optimum Black. Its made for oil applications and also new lightweight materials(such as our magnesium).

I removed mine entirely from sled to do it on the bench, you can do it on sled if you want. Best time to do this is during an oil change, so you are already draining oil from sled for change. I removed my lower side panel as I have "Rivnuts" now which replaced rivets. I great mod that makes oil changes so much easier(see page one for Rivnut info and detailed instructions). I removed lower panel, Muffler, and then the tank itself. Removing the silver screws. Black screws are for the chaincase, and if you do this on the bench, you will also need to remove it too. I was changing my gearing back to stock, so I was opening it anyway.

Take it all apart, get all the oil out....and once dried out for a few days, clean it again real good with brake cleaner which dries fast. The key on assembly is to mate the two sides so silicone touches, but do NOT tighten screws. Just mate them and then read your silicone instructions, mine said to wait ONE HOUR before tightening screws and torquing down.

This wait time is crucial IMO....If you tighten them down right off the bat, 95% of the silicone just squeezes out, so that is no good.

The Nice thing about if you do it on sled is the weight of the tank wont squeeze out too much silicone like it does on bench when you set tank onto case cover....I thought the silicone might be thicker, and not have squeezed out as much as mine did just from weight of tank. So I would have waited some time for it to thicken some, or maybe make an even larger bead..... or maybe just try to slide it on in a different manner rather then laying it down on top. If installed on sled it would be slid on from side, and then could regulate how tight you allow it to go initially.

Final torque.....I have two spec sheets, one says 8ft lbs torque for chaincase and other says 12 ft lbs. I have been told the chaincase and oil tank are same torque. I went with 8 first, then 10 or so....I do not believe you need to go to 12 ft lbs. I like 10 to 11 max. Be sure to allow the silicone to setup for an hour min with this Optimum, other brands may be more or less time.

Remove hose to help drain ALL oil out

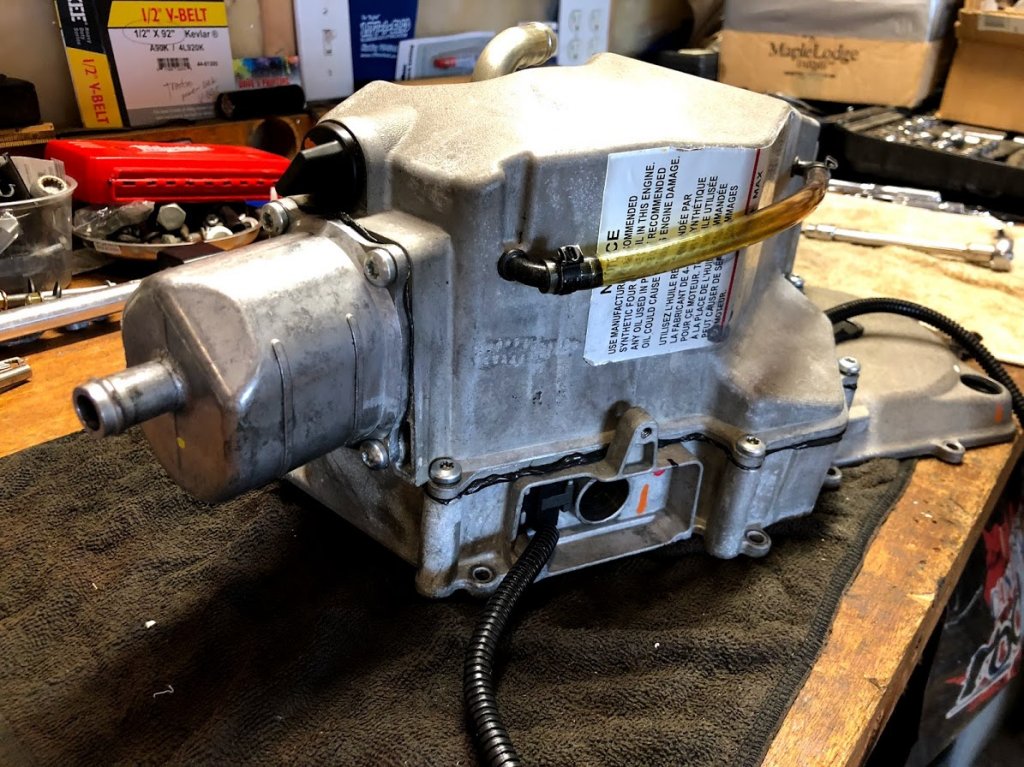

Tank removed from Chaincase cover

See break in silicone where mine was seeping out

Let it drip out for a few days

Chaincase cover, let drip out and then clean out good with brake cleaner

Tank cleaned out good with brake cleaner, all plastics removed

Checked my sight glass, seems good and tight

Showing O rings and assembly orientation

Cleaned and plastics reinstalled, See groove where you lay thick 1/4'' to 3/8'' wide silicone bead, tank side only.

Siliconed and just set in place, not tightened at all(wait one hour with Optimum before torquing to 10ft lbs or so)

Most all these oil tanks tend to leak/seep eventually. The key is to get them drained and dry/clean to make a good seal with new Silicone RTV. I went with Permatex Optimum Black. Its made for oil applications and also new lightweight materials(such as our magnesium).

I removed mine entirely from sled to do it on the bench, you can do it on sled if you want. Best time to do this is during an oil change, so you are already draining oil from sled for change. I removed my lower side panel as I have "Rivnuts" now which replaced rivets. I great mod that makes oil changes so much easier(see page one for Rivnut info and detailed instructions). I removed lower panel, Muffler, and then the tank itself. Removing the silver screws. Black screws are for the chaincase, and if you do this on the bench, you will also need to remove it too. I was changing my gearing back to stock, so I was opening it anyway.

Take it all apart, get all the oil out....and once dried out for a few days, clean it again real good with brake cleaner which dries fast. The key on assembly is to mate the two sides so silicone touches, but do NOT tighten screws. Just mate them and then read your silicone instructions, mine said to wait ONE HOUR before tightening screws and torquing down.

This wait time is crucial IMO....If you tighten them down right off the bat, 95% of the silicone just squeezes out, so that is no good.

The Nice thing about if you do it on sled is the weight of the tank wont squeeze out too much silicone like it does on bench when you set tank onto case cover....I thought the silicone might be thicker, and not have squeezed out as much as mine did just from weight of tank. So I would have waited some time for it to thicken some, or maybe make an even larger bead..... or maybe just try to slide it on in a different manner rather then laying it down on top. If installed on sled it would be slid on from side, and then could regulate how tight you allow it to go initially.

Final torque.....I have two spec sheets, one says 8ft lbs torque for chaincase and other says 12 ft lbs. I have been told the chaincase and oil tank are same torque. I went with 8 first, then 10 or so....I do not believe you need to go to 12 ft lbs. I like 10 to 11 max. Be sure to allow the silicone to setup for an hour min with this Optimum, other brands may be more or less time.

Remove hose to help drain ALL oil out

Tank removed from Chaincase cover

See break in silicone where mine was seeping out

Let it drip out for a few days

Chaincase cover, let drip out and then clean out good with brake cleaner

Tank cleaned out good with brake cleaner, all plastics removed

Checked my sight glass, seems good and tight

Showing O rings and assembly orientation

Cleaned and plastics reinstalled, See groove where you lay thick 1/4'' to 3/8'' wide silicone bead, tank side only.

Siliconed and just set in place, not tightened at all(wait one hour with Optimum before torquing to 10ft lbs or so)

Last edited:

Byam

TY 4 Stroke Guru

Nicely done

Thanks for taking time doing that for us

Thanks for taking time doing that for us

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

New Clutch Parts w/updated B/O Spring instructions

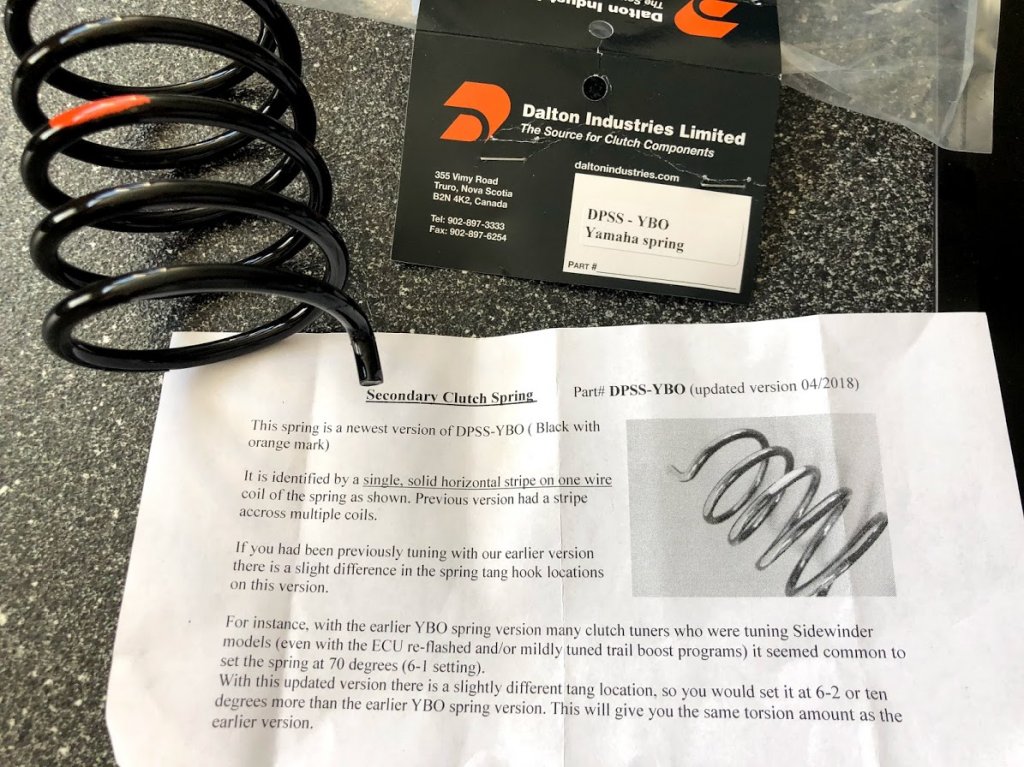

Will be testing a 37/35 helix this season with my new stock gearing & lowered offset. Also Dale sent me the replacement B/O Secondary spring. I had no issues with my B/O last yr, but nice to see Dale being proactive on these.

Take note of the new updated instructions for the NEW B/O....will now be set to 6/2(80 degrees).

Dan

Will be testing a 37/35 helix this season with my new stock gearing & lowered offset. Also Dale sent me the replacement B/O Secondary spring. I had no issues with my B/O last yr, but nice to see Dale being proactive on these.

Take note of the new updated instructions for the NEW B/O....will now be set to 6/2(80 degrees).

Dan

Last edited:

kimcoop1324

Extreme

Hey Dan where did you find that 15 degree tube with the hose connector? Did you buy it that way or weld it on yourself? What size barb fittings would I need to hook up my 2 hoses to the cai. Thanks mikeCAI(Cold Air Intake) - Mocking up my design

NOTE: For finished CAI pics: Quick Jump Link

After getting one of the originals out there last winter for Buds sled, I knew I wanted to tweak my own design, to allow for more airflow to the clutches.

Lots of benefits from a CAI as noted by all the tuners. HP increases and more importantly for me, better throttle response. Most will agree that a TUNE is needed to run a CAI, and I will install mine permanently after I get my initial break in miles on bone stock engine.

Just the removal of the quite large airbox alone is a big bonus for airflow, as seen in these pics.

My design has always been about NOT blocking the front stock VENT, and so I am going with a smaller k&n then some early designs, and will raise it up as high as the hood allows, so there is lots of open vent below the filter flowing air directly back to the clutches, this will even further cool the already cool running yamaha clutches..

I do this by using 2.5" OD tubing with a slight 15 degree bend in it. This in conjunction with the 2.5" ID 90 degree silicone elbow, will allow me to twist the tube/elbow to get it exactly where I want it. I will come back and EDIT this post when the k&n arrives next week. I wanted to hold off on ordering the filter until I was able to mock up the tube and elbow. I also ordered my "outerwears" filter sock which I highly recommend.

View attachment 131966 View attachment 131967 View attachment 131968 View attachment 131969 View attachment 131970 View attachment 131971 View attachment 131972 View attachment 131973 View attachment 131974 View attachment 131975 View attachment 131976 View attachment 131977

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

That section I had here from an old intake kit. Its not something easily found. But if you google aluminum tubing, you will come across lots on ebay with 10 and 15 degree angles. For the vacuum lines, you can pick up those small inserts I used, which bolt into the silicone nicely.Hey Dan where did you find that 15 degree tube with the hose connector? Did you buy it that way or weld it on yourself? What size barb fittings would I need to hook up my 2 hoses to the cai. Thanks mike

Dan

Hammer70

GRIPNRIP

- Joined

- Sep 6, 2015

- Messages

- 824

- Location

- Niagara, Ontario.

- Country

- Canada

- Snowmobile

- 82SS440/96VMAX/02SRX/08APE/15SRVIPER/17SIDEWINDER

Hi I know it’s old thread but we’re did you purchase I have been looking all over for this.Hi Dan,

Awesome design on the CAI, after looking through the pics and basically copying yous

Hi Dan

Great job on the CAI I am pretty much borrowing your design. I think there is a better way to mount the vacuum hose on the PVC and have attached a pic. These look awesome for this purpose. They come with a punch for the hole and are inserted from the inside with rubber o-ring for seal followed up by a washer and nut on the outside

View attachment 132440

Thanks Pan

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Hey Brother....Hi I know it’s old thread but we’re did you purchase I have been looking all over for this.

Thanks Pan

I designed my own CAI.....its quite simple really. Not sure what part you need, but i have most the stuff posted in this build thread, page one 1st post has many direct links to all the stuff ive done so far.

Dan

kimcoop1324

Extreme

Hey Dan just curious what size self sealing take off you used on your silicone elbow? Is the hose coming off your 15 degree bend the same size as well? Thanks mikeCold Air Intake Installed(CAI)- Finished(Part 3)

Its time for all the goodies!

Since I got on my 550 stock miles, I got to do my oil change, and since I had to remove muffler to get into chaincase, it all made sense to do the 22 top gear, muffler, and TUNE, which meant it was time for my own CAI to go on.

I mocked up my design back on the fall, which is earlier on in this thread(All quick jump links are on post #1). I decided to get a screw on nipple for the rear vent hose that comes over from valve cover, it worked out very nicely.

This design has a massive amount of airflow UNDER the CAI, to blow directly on clutches and belt. This more then anything is quite impressive, to have such direct flow will surely take alot of temp off the clutches. The design with a slight bend in tube in addition to the silicone elbow, allows for twisting the CAI into place very high.

A modest sized k&n air filter also allows for more air flow through the stock screen/vent, and down to the clutches/belt.

The next thing I did was to zip tie the final placement, to the side panel. This will stop it from any movement when pounding through the junk. I have not seen other kits have any type of help holding it up, but I wanted to be sure this stays put and does not wear anywhere. I also installed my Outerwears filter sock.

Upon firing it up.....I was blown away how INSTANT the throttle feels compared to before, just on the stand. Im dying to take this baby for a ride now!

-K&N Part# SN-2570

-Outerwears filter sock - #20-1469

Dan

LINK for barbed Vent inserts: https://www.viperperformance.co.uk/...103_self-seal-take-offfor-silicone-hoses.html

View attachment 136058 View attachment 136059 View attachment 136060 View attachment 136062 View attachment 136063 View attachment 136064 View attachment 136065 View attachment 136066 View attachment 136067 View attachment 136068 View attachment 136069 View attachment 136070 View attachment 136071 View attachment 136072 View attachment 136073 View attachment 136074 View attachment 136075 View attachment 136076 View attachment 136077 View attachment 136078

H2Snow

Newbie

Hey Dan just curious what size self sealing take off you used on your silicone elbow? Is the hose coming off your 15 degree bend the same size as well? Thanks mike

H2Snow

Newbie

Hi Dan,

Your info is great, many thanks!

Just picked up a new 2018 L TX SE, adding most of your changes. I am looking for a primary holder, similar to that shown in your belly pan protector install. I think it is different than other Yamaha holders. Want to make sure I get the correct one. Do you have a part # and supplier for that please?

Thanks

Jeff

Your info is great, many thanks!

Just picked up a new 2018 L TX SE, adding most of your changes. I am looking for a primary holder, similar to that shown in your belly pan protector install. I think it is different than other Yamaha holders. Want to make sure I get the correct one. Do you have a part # and supplier for that please?

Thanks

Jeff

Similar threads

- Replies

- 21

- Views

- 36K

- Replies

- 4

- Views

- 32K

- Replies

- 25

- Views

- 48K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.