ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Coolant Hose Protectors(By BOP)

Last season there were a few guys who had their coolant hose torn/ripped due to ice chunks. It does seem most who had this happen run no studs. Studs likely help chew up ice before it can cause a problem. Some that had this happen noted the ice actually pushed up the tunnel and therefore can tear off the small coolant hose.

I never had an issue, but my clamps were not tight enough and seeping coolant before I ever rode the sled. I believe loose clamps could also be a reason the coolant hose may get torn off by ice and end up with a ruptured hose.

Since I had my skid out anyway, I felt this was a good time to work on this issue. Travis at Barn of Parts has been working on this design for awhile, and I was hounding him about these since last season,LOL. Glad to see he got these out to me.

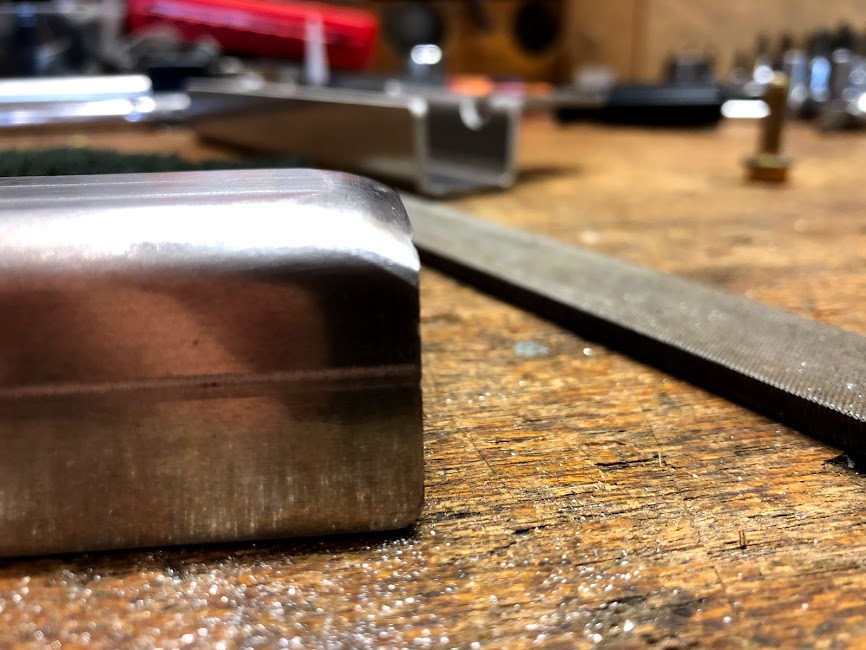

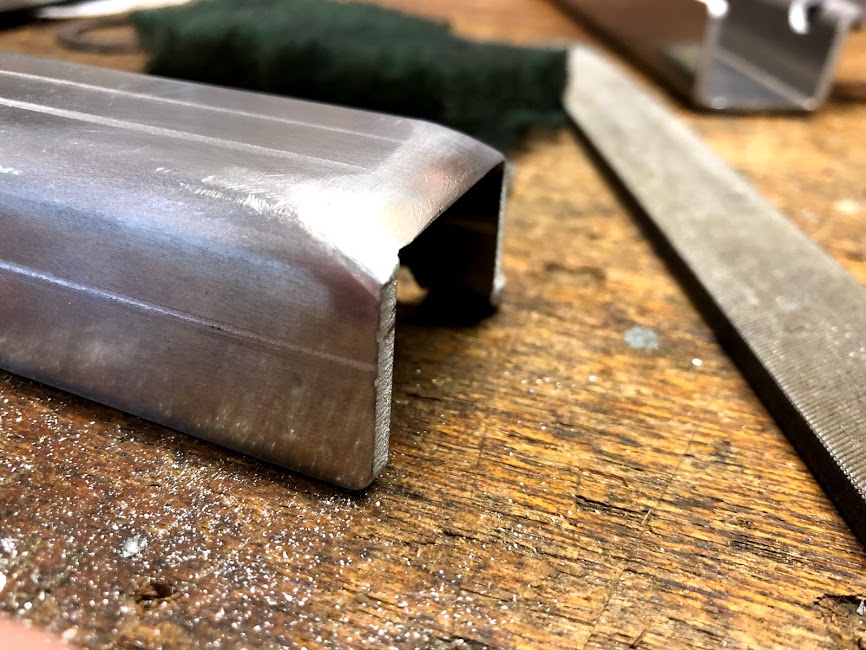

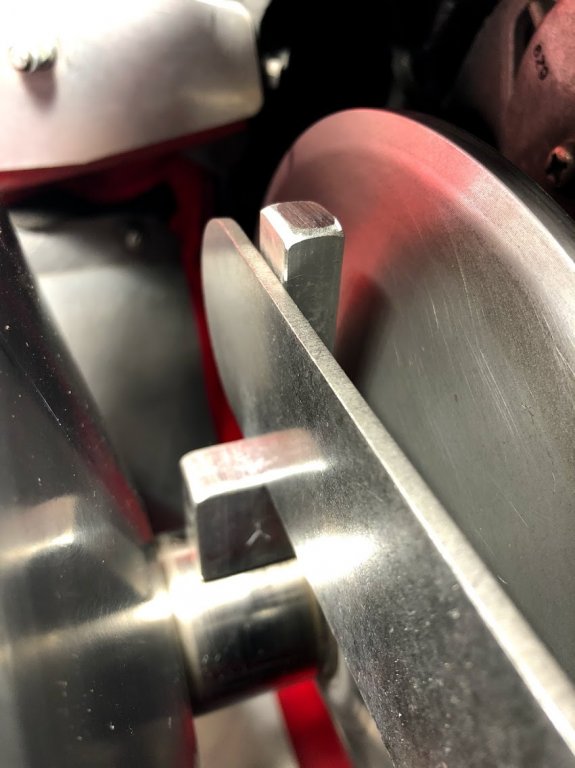

I did do a few tweaks to them before installing. First I ground off the leading edge where track lugs "may' touch initially...Since these are a fairly thick aluminum, I wanted to be sure the lugs would not tear if they rub. I ground them down, then filed them to a rounded off edge. Ended up with some sanding to get them nice and smooth.

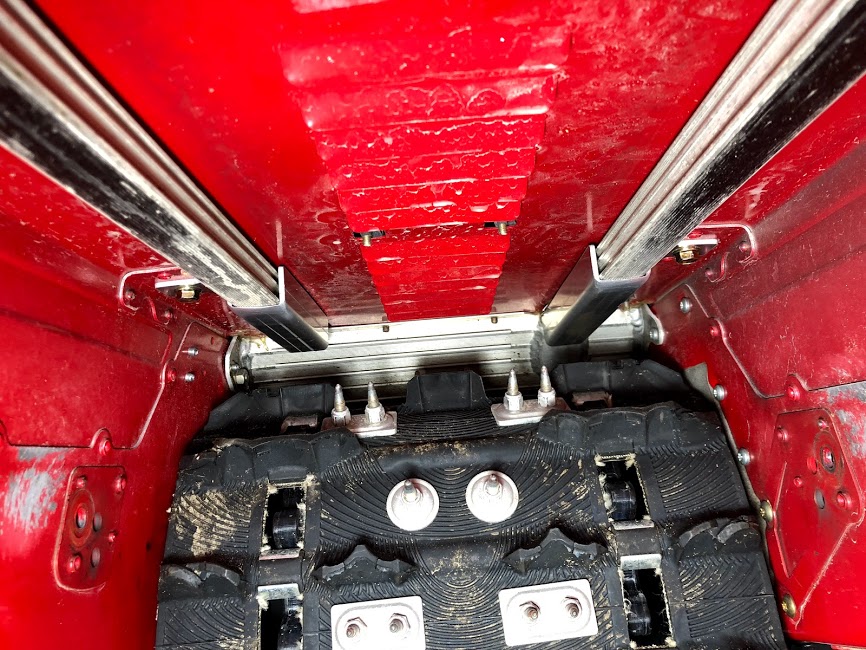

I also checked fitment, and decided to compress the width just a tad in my vice, to get that perfect tight fitment so there is zero play on coolant runner. The sizing is really nicely done by Travis, and I do not see any issues with the fitment. They do not touch the tunnel so they wont chafe away over time there, very nice.

Dan

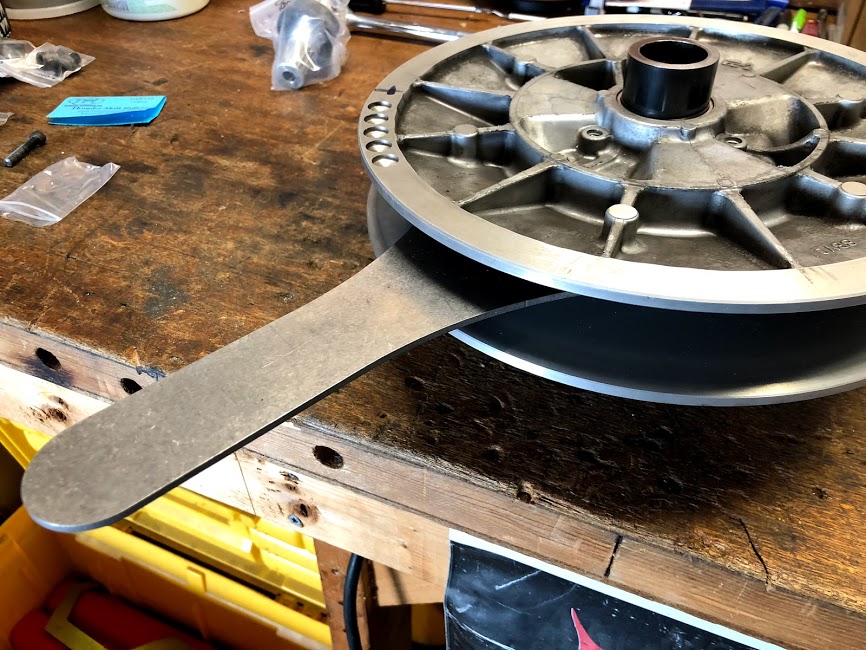

Just arrived parts, Notice thick leading edge.

Ground, filed then sanded to a nice rounded leading edge.....

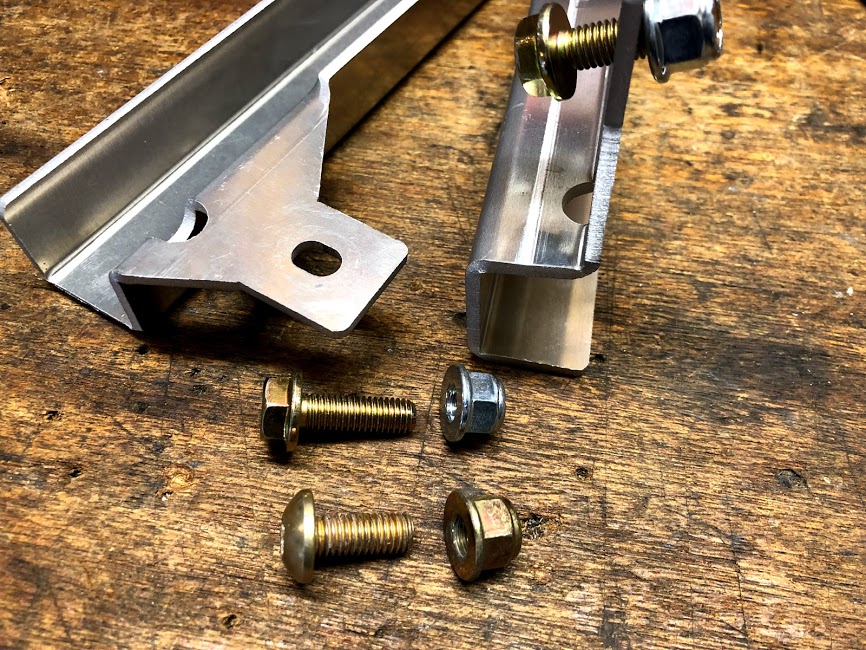

Remove two torx screws on gas tank shroud(each side above foot) and hold back, to access the 13mm locknut.

Stock Torx(40) Bolt from below

T40 needed to remove stock bolt from below tunnel....

Travis includes longer hex head bolts/locknuts.....

Nice smooth transition for lugs if they touch....Very snug fit is what you want.

Protected from all sides now....and will not rub against tunnel.

Last season there were a few guys who had their coolant hose torn/ripped due to ice chunks. It does seem most who had this happen run no studs. Studs likely help chew up ice before it can cause a problem. Some that had this happen noted the ice actually pushed up the tunnel and therefore can tear off the small coolant hose.

I never had an issue, but my clamps were not tight enough and seeping coolant before I ever rode the sled. I believe loose clamps could also be a reason the coolant hose may get torn off by ice and end up with a ruptured hose.

Since I had my skid out anyway, I felt this was a good time to work on this issue. Travis at Barn of Parts has been working on this design for awhile, and I was hounding him about these since last season,LOL. Glad to see he got these out to me.

I did do a few tweaks to them before installing. First I ground off the leading edge where track lugs "may' touch initially...Since these are a fairly thick aluminum, I wanted to be sure the lugs would not tear if they rub. I ground them down, then filed them to a rounded off edge. Ended up with some sanding to get them nice and smooth.

I also checked fitment, and decided to compress the width just a tad in my vice, to get that perfect tight fitment so there is zero play on coolant runner. The sizing is really nicely done by Travis, and I do not see any issues with the fitment. They do not touch the tunnel so they wont chafe away over time there, very nice.

Dan

Just arrived parts, Notice thick leading edge.

Ground, filed then sanded to a nice rounded leading edge.....

Remove two torx screws on gas tank shroud(each side above foot) and hold back, to access the 13mm locknut.

Stock Torx(40) Bolt from below

T40 needed to remove stock bolt from below tunnel....

Travis includes longer hex head bolts/locknuts.....

Nice smooth transition for lugs if they touch....Very snug fit is what you want.

Protected from all sides now....and will not rub against tunnel.

Last edited:

RAMSOMAIR

TY 4 Stroke God

Rubbing the tunnel is not as big a concern as the guards rubbing the heat exchangers themselves. I may ad a strip of foam tape!

RAMSOMAIR

TY 4 Stroke God

Great tutorial as usual Dan.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

The way these fit, there is no movement at all....Its not touching the coolant runner anywhere but around the fins and with the perfect fitment it cannot rub. Its the tunnel where I did not want it wearing against up top. These are lightweight alum.Rubbing the tunnel is not as big a concern as the guards rubbing the heat exchangers themselves. I may ad a strip of foam tape!

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

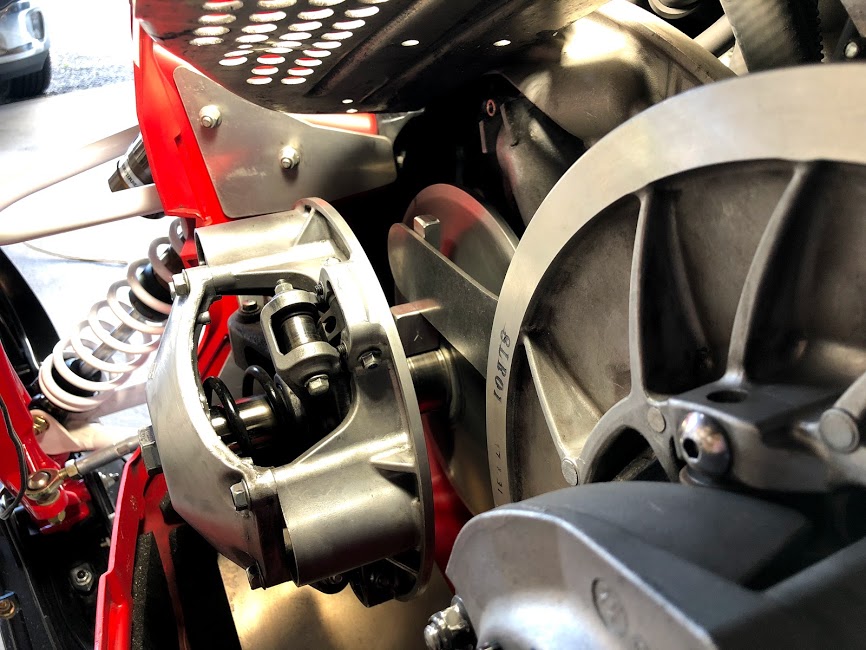

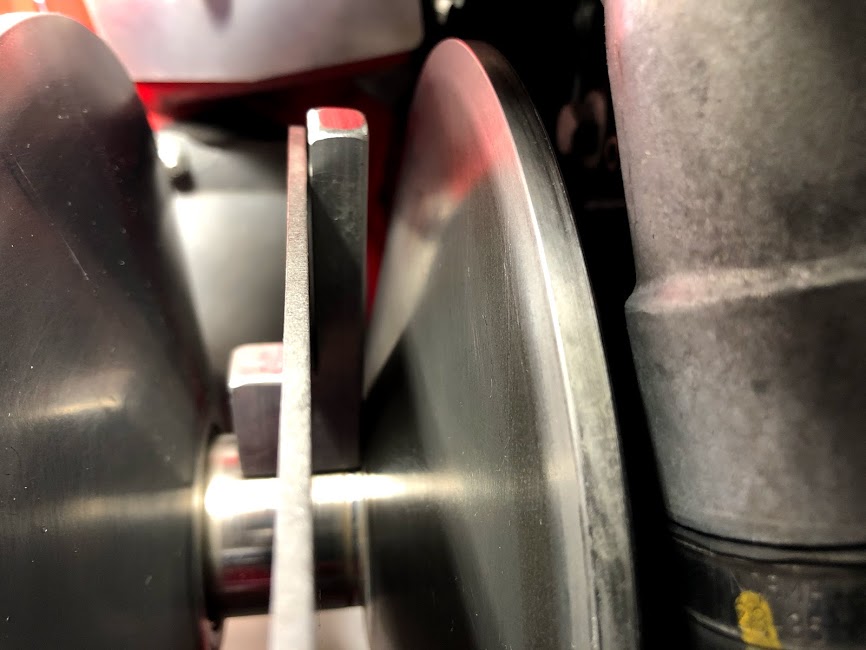

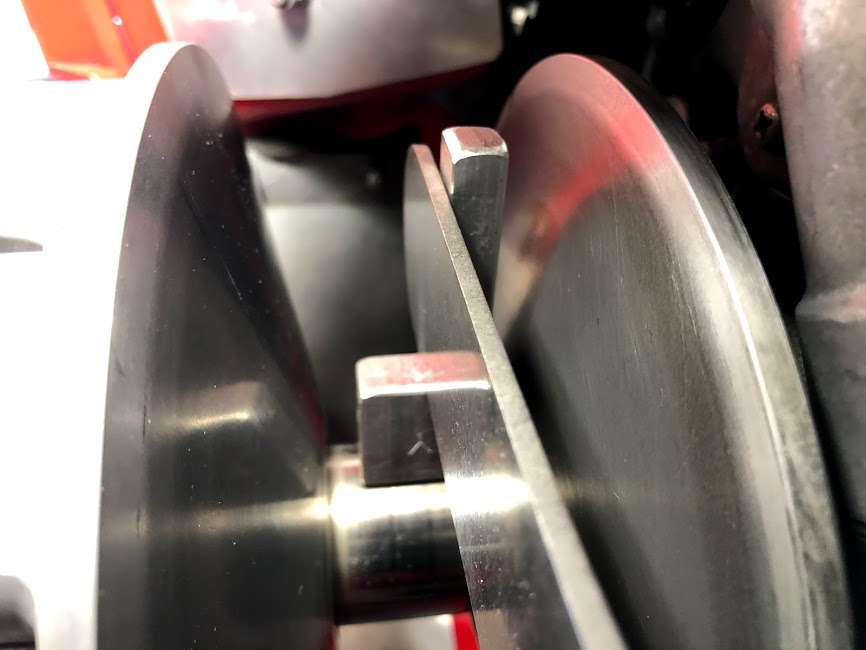

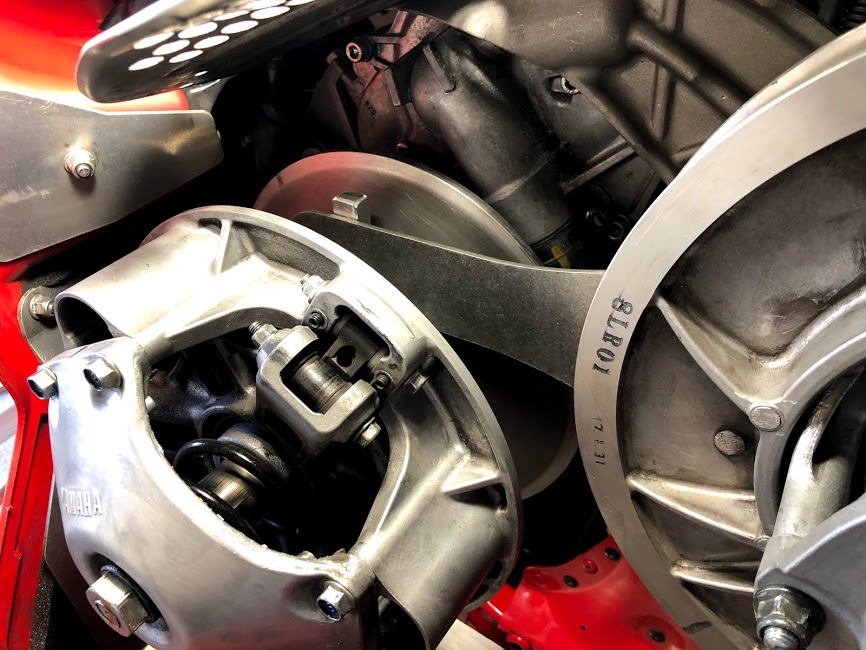

Hurricane Alignment Bar

Finally got the sled all back together today, and got time to work on the clutches. This is the first time I set Dave's bar onto my clutches. I don't want to give out Daves specs, as I believe everyone should buy one of these and set theirs up, since not all the tolerances are same from sled to sled.

At the end of last season I removed 4mm from my secondary hub backside(where it sets against the shims). I ran that on my last trip, with a 1.5mm shim.

Today I set Dave's bar on and I was still not back far enough to meet Dave's alignment bar correctly. So I removed the 1.5mm shim, and then the offset was perfect with Dave's bar. So for me, I had to remove a full 4mm and have ALL SHIMS REMOVED, so now the hub is directly against the circlip.

*NOTE: Its important to understand not all sleds clutches are the same, and my primary clutch may be pushed in by 1mm or so, possibly from a snapped belt slamming primary together and pushing stub shaft inward. So 3mm machining of secondary hub may be enough for many.

See the next post on my thoughts on float with the new offset......

Dan

Pics of the Hurricane alignment bar.....

Finally got the sled all back together today, and got time to work on the clutches. This is the first time I set Dave's bar onto my clutches. I don't want to give out Daves specs, as I believe everyone should buy one of these and set theirs up, since not all the tolerances are same from sled to sled.

At the end of last season I removed 4mm from my secondary hub backside(where it sets against the shims). I ran that on my last trip, with a 1.5mm shim.

Today I set Dave's bar on and I was still not back far enough to meet Dave's alignment bar correctly. So I removed the 1.5mm shim, and then the offset was perfect with Dave's bar. So for me, I had to remove a full 4mm and have ALL SHIMS REMOVED, so now the hub is directly against the circlip.

*NOTE: Its important to understand not all sleds clutches are the same, and my primary clutch may be pushed in by 1mm or so, possibly from a snapped belt slamming primary together and pushing stub shaft inward. So 3mm machining of secondary hub may be enough for many.

See the next post on my thoughts on float with the new offset......

Dan

Pics of the Hurricane alignment bar.....

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

.

Last edited:

Interesting and I think you make a good point. So who is going to make a adjuster that butts against the shaft/washer and still adjust deflection? This would eliminate the washers between sheaves and still have same Float and Deflection as you have done. But adjustable. Back to basics and the K.I.S.S. method. I think you are on to something.Deflection, Offset & Floating the Secondary

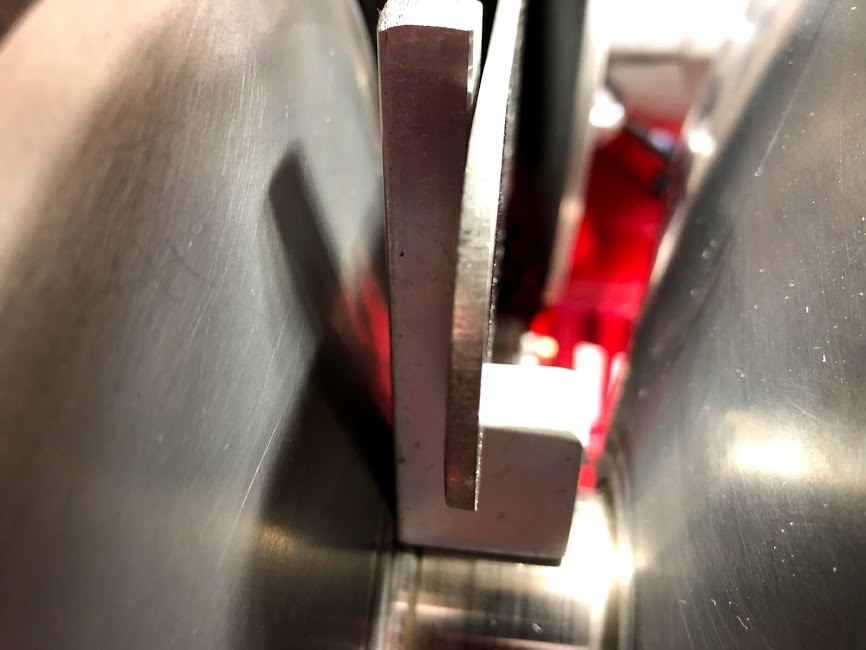

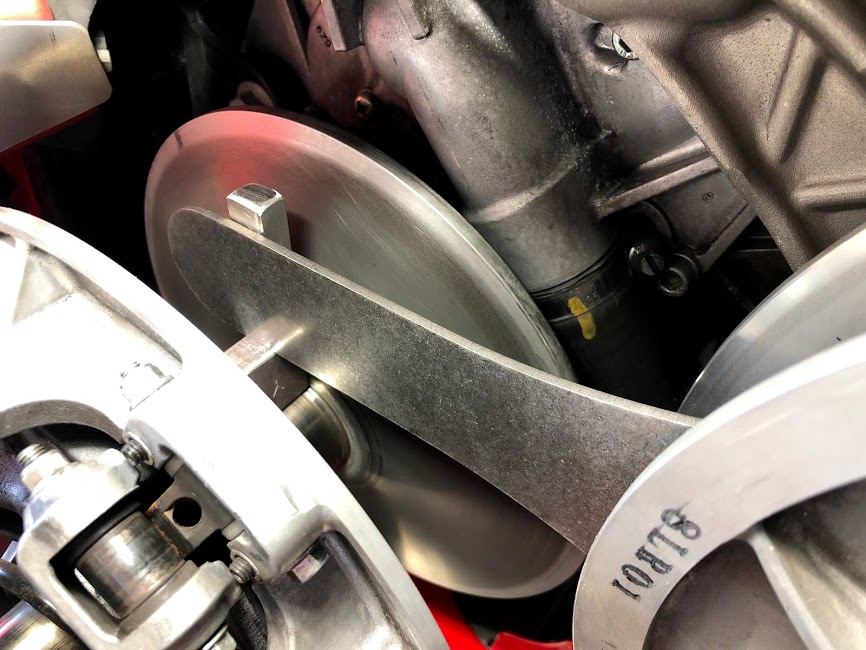

When lowering the offset further, by machining the secondary hub(4mm in my case) we have now created more room for "float". The Secondary will move in/outward(float) on the Jshaft once into the shift(need to mockup without spring to see the float amt.)

With the stock setup, the aluminum spacer(float plug) and large flat washer are designed to work together to allow some float(once into the shift) and there are two smaller shim washers that are used to adjust your belt deflection.

When you machine down your secondary to lower offset, the stock float plug and deflection washers become too long. So you need to use a belt deflection adjuster.

What I see upon mockup, is the amount of float when set where the Hurricane bar wants it, becomes alot more then originally designed. And this may be an issue, since the secondary may float outward 7mm(w/stock setup) and upwards of 1/2 inch(with belt adjusters) upon deceleration! So what can happen corner to corner is the secondary may float outward when you decel, then you whack the throttle and you are nowhere near the offset your bar wants since the secondary simply cannot float back inward under acceleration, it has too much pull on the belt and cant float inward. It will typically only float when you let off/decel.

Talking with Dave at the show...he prefers no float at all. On the Apex we always had some float, and it was easy to set the amt up perfectly. With the winder setup its same as my 12 cat was, and the helix is out further then the hub, and uses this for deflection.

So to do what I want to do.....I went to a proper float(like the apex had) and so I had to use shims for deflection, and then use a 1-3/8" OD washer and a 1.5" OD washer that goes against hub(but fits inside helix) and stock bolt, and a shortened float plug and you may need to use a washer or two depending how much you cut back on float plug, as the stock clutch bolt may be too long and bottom out in Jshaft. Hard to explain it all so I did a video below which might help.

With the setup now...I am set to where the Hurricane bar wants it, and set it up for approx 1.5mm of outward float only, and this is at idle or anywhere on the shift.

Video below trying to explain this....lol

Dan

Large secondary shims for deflection(between sheaves)

View attachment 142632

View attachment 142633

View attachment 142634

2mm total seems good for new ultimax deflection

View attachment 142636

View attachment 142637

View attachment 142655

7mm of original float plug showing(to hub) after lowered offset to 57mm(float plug needs to be shortened)

View attachment 142638

Both OSP & BOP belt adjusters are cutout so hub floats MUCH further outward once into the shift compared to stock flat washer

View attachment 142640

Smaller washers(1-3/8''min to 1.5" max OD)which fit inside of helix bushing.

View attachment 142642

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Exactly brother.....I have two diff designs here and both designers cutout for hub, which is too much for what i want to do. Possibly this is the reason so many have belt issues? I may modify my belt adjuster so I can have a simple belt change tool, but will keep my float setup as I have it now.Interesting and I think you make a good point. So who is going to make a adjuster that butts against the shaft/washer and still adjust deflection? This would eliminate the washers between sheaves and still have same Deflection as you have done. But adjustable. Back to basics and the K.I.S.S. method. I think you are on to something.

We'll see how things go this season now with several changes to my setup.

Dan

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,242

- Reaction score

- 2,679

- Points

- 1,733

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

My offset tool had a slight bow in it. I had to make it perfectly straight.

With the clutches lined up perfect why would you want any float in the secondary?

With the clutches lined up perfect why would you want any float in the secondary?

Michael Potter

Newbie

- Joined

- Mar 9, 2016

- Messages

- 14

- Reaction score

- 6

- Points

- 213

- Location

- Ontario

- Country

- Canada

- Snowmobile

- Yamaha Sidewinder

Hi Dave. Did you take the float plug to a machinist to remove the 4mm? Also where did you get the outside washers?

Thanks

Mike

Thanks

Mike

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

My offset tool had a slight bow in it. I had to make it perfectly straight.

With the clutches lined up perfect why would you want any float in the secondary?

That is a question I have contemplated often.

First question is, do we know for sure they are perfectly aligned? I think the jury is still out on that. Im sure hoping that the new offset works though!

I think float is a good thing to a certain extent for trail riding. For drag racing not really. The issue I have found is, the AMOUNT of float from the factory is multiplied immensely with some of the aftermarket belt adjusters, and the other thing is when we lower the offset from stock we increase the float by that same amount.

I know for me, I installed a belt adjuster from day one. I had the OSP initially, then swapped to the BOP...But I noticed both of these adjuster have material removed from backside, so the hub will float outward alot more then stock large washer design. Makes me wonder. Most stock guys also run stock float plug/washer/deflection setup.....and seem to not blow belts. For corner to corner riding, too much float could easily be detrimental.

My new setup, as shown above has only 1.5mm of float at all times, very similar to my apex.

Dan

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Hi Dave. Did you take the float plug to a machinist to remove the 4mm? Also where did you get the outside washers?

Thanks

Mike

I just used washers I had here in the shop.....And I just shortened the float plug cutting it off. Its just aluminum. I cleaned it up with file. I would not consider doing any of this unless you fully understand what you want, and are prepared to go back to stock if need be. I have several float plugs here so its no biggie for me.

Also I am not 100% sure a lowered offset is the cure for belt life, I sure hope it is but at this point these are all tests, and just hoping me or someone figures these belts out, as I love the sled alot. Belt life is where the love ends....lol.

Dan

Last edited:

Fleecer

Lifetime Member

- Joined

- Jun 13, 2014

- Messages

- 1,180

- Reaction score

- 1,691

- Points

- 1,328

- Country

- USA

- Snowmobile

- 2019 SRX

I just used washers I had here in the shop.....And I just shortened the float plug cutting it off. Its just aluminum. I cleaned it up with file. I would not consider doing any of this unless you fully understand what you want, and are prepared to go back to stock if need be. I have several float plugs here so its no biggie for me.

Also I am not 100% sure a lowered offset is the cure for belt life, I sure hope it is but at this point these are all tests, and just hoping me or someone figures these belts out, as I love the sled alot. Belt life is where the love ends....lol.

Dan

Dan,

Great post and thanks for taking the time to share your thoughts with all of us. You just answered a question that has been plaguing me for the last 2 seasons. Here's why:

A lot of my riding is high speed RR bed riding. I'll run 1-1.5 miles high 120s/low 130s, slow down to 90-100, round a corner, open up another mile 130, slowdown, round corner open up another stretch 130-133 for 1.5 miles, etc, etc, over and over for 30-40 miles. As you can imagine, this is very hard on belts. Many times while doing this I've experienced severe belt slip at approximately 117mph. At this speed you would think it would be impossible to smell belt slippage, yet I smell it so bad that I can only compare it to holding brake on in parking lot while holding throttle wide open. For years I've been perplexed as to the cause of this. I just read your post and you provided the answer. At high speeds the secondary is shifted out causing a lot of float, then when I deccelerate for a corner, the clutch floats to the outside. When I get in it again the secondary is so out of line the belt slips/burns.

What are your thoughts??

I'm leaning towards adjusting deflection using shims like you and mounting fixed secondary with no float.

Will eliminating float conversely create heat upon deceleration? Thoughts?

A little float goes a long way. Back to basics for me. It just makes sense.Dan,

Great post and thanks for taking the time to share your thoughts with all of us. You just answered a question that has been plaguing me for the last 2 seasons. Here's why:

A lot of my riding is high speed RR bed riding. I'll run 1-1.5 miles high 120s/low 130s, slow down to 90-100, round a corner, open up another mile 130, slowdown, round corner open up another stretch 130-133 for 1.5 miles, etc, etc, over and over for 30-40 miles. As you can imagine, this is very hard on belts. Many times while doing this I've experienced severe belt slip at approximately 117mph. At this speed you would think it would be impossible to smell belt slippage, yet I smell it so bad that I can only compare it to holding brake on in parking lot while holding throttle wide open. For years I've been perplexed as to the cause of this. I just read your post and you provided the answer. At high speeds the secondary is shifted out causing a lot of float, then when I deccelerate for a corner, the clutch floats to the outside. When I get in it again the secondary is so out of line the belt slips/burns.

What are your thoughts??

I'm leaning towards adjusting deflection using shims like you and mounting fixed secondary with no float.

Will eliminating float conversely create heat upon deceleration? Thoughts?

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,242

- Reaction score

- 2,679

- Points

- 1,733

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Interesting and I think you make a good point. So who is going to make a adjuster that butts against the shaft/washer and still adjust deflection? This would eliminate the washers between sheaves and still have same Float and Deflection as you have done. But adjustable. Back to basics and the K.I.S.S. method. I think you are on to something.

This can be done very easily by just installing the large stock washer at the head of the bolt then using stock belt adjuster shims between the float fixed washer that Dan has added and the large stock washer.

My belt change tool is a piece of pcv pipe that goes between the large washer and the helix to compress the clutch. The chunk of PVC pipe fits in my tool bag fine.

Similar threads

- Replies

- 42

- Views

- 14K

- Replies

- 7

- Views

- 32K

- Replies

- 74

- Views

- 11K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.