Fast

TY 4 Stroke Guru

- Joined

- Sep 25, 2018

- Messages

- 996

- Reaction score

- 228

- Points

- 488

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

Thanks for the specs,that's crazy that it's out that much,who's building our sleds yamaha or articat?could the motor be positioned for the team clutches and not re-positioned for the yamaha clutches,I'll be checking my srx if it ever shows up and taking this up with yamaha since that's unacceptableMy service manual shows spec at 58.1mm-61.1mm

Mine with no shim measured at 60.3mm so I machined my secondary shaft.

Now used Hurricane alignment tool to put in spec. And used selected shim and a custom shim.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Its just that we are trying to lower offset to meet Hurricane bar specs.Thanks for the specs,that's crazy that it's out that much,who's building our sleds yamaha or articat?could the motor be positioned for the team clutches and not re-positioned for the yamaha clutches,I'll be checking my srx if it ever shows up and taking this up with yamaha since that's unacceptable

Fast

TY 4 Stroke Guru

- Joined

- Sep 25, 2018

- Messages

- 996

- Reaction score

- 228

- Points

- 488

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

Ya I see the majority looking for a lower offset but if the specs are 58.1-61.1 and you can only get 60.3 that's a problem you should be able to adjust it for spec so in theory you should of been able to lower yours without maching your clutch unless your running below 58mm,I want to start out at 59mm and go from there,does the belt run to the top of the primary?or is there room to machine in a little more overdrive like the apex.I was able to take 60thou. off those clutchesIts just that we are trying to lower offset to meet Hurricane bar specs.

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Reaction score

- 1,437

- Points

- 958

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

Rubbing the tunnel is not as big a concern as the guards rubbing the heat exchangers themselves. I may ad a strip of foam tape!

Even if the guards rub on the heat exchangers they will never do any damage. How far can they rub if indeed they do which I doubt could happen. If that is a concern then you better put some tape everywhere the exchangers touch the tunnel. You're going to need a lot of tape.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

As I said, the spec is LOWER and so mine needed machining. We have all been round and round, and I decided to try Hurricane bar spec this season.Ya I see the majority looking for a lower offset but if the specs are 58.1-61.1 and you can only get 60.3 that's a problem you should be able to adjust it for spec so in theory you should of been able to lower yours without maching your clutch unless your running below 58mm,I want to start out at 59mm and go from there,does the belt run to the top of the primary?or is there room to machine in a little more overdrive like the apex.I was able to take 60thou. off those clutches

34pontiac

Expert

- Joined

- Nov 16, 2014

- Messages

- 291

- Reaction score

- 122

- Points

- 738

- Location

- WI

- Country

- USA

- Snowmobile

- Sidewinder

Apex

So now that I used the hurricane offset tool and removed 3mm.

Does that makes my new BOP adjuster useless because you say there is too much float with an adjuster??

Great ...

Does that makes my new BOP adjuster useless because you say there is too much float with an adjuster??

Great ...

Last edited:

Bigblue1

TY 4 Stroke Junkie

- Joined

- Nov 29, 2007

- Messages

- 563

- Reaction score

- 272

- Points

- 1,108

- Location

- NY

- Country

- USA

- Snowmobile

- Sidewinder RTX-LE

Apex SE

So Dan my belts weren't snapping. They were exploding into pieces......stock after 400 miles. So I did the rollers in secondary, rollers in primary (one of the bushings was sticking), and installed TP orange springs and TP belt adjuster. Now getting around 1,000 miles with one stint at 1,400, after TD Powertrail and Dalton weight set up. I could almost live with that but no, I want 2,000 miles out of a belt. My Apex never blows a belt past 3,000 miles. So naturally, viewing your videos and researching on this forum, I got the alignment tool after checking offset. It was off with no shims or screws on the back side so I machined 2mm off since putting me at 58.7mm. Your float post is interesting. I have been running TP adjuster backwards since the back of it is perfectly flat. We'll see what happens this winter.Deflection, Offset & Floating the Secondary

When lowering the offset further, by machining the secondary hub(4mm in my case) we have now created more room for "float". The Secondary will move in/outward(float) on the Jshaft once into the shift(need to mockup without spring to see the float amt.)

With the stock setup, the aluminum spacer(float plug) and large flat washer are designed to work together to allow some float(once into the shift) and there are two smaller shim washers that are used to adjust your belt deflection.

When you machine down your secondary to lower offset, the stock float plug and deflection washers become too long. So you need to use a belt deflection adjuster.

What I see upon mockup, is the amount of float when set where the Hurricane bar wants it, becomes alot more then originally designed. And this may be an issue, since the secondary may float outward 7mm(w/stock setup) and upwards of 1/2 inch(with belt adjusters) upon deceleration! So what can happen corner to corner is the secondary may float outward when you decel, then you whack the throttle and you are nowhere near the offset your bar wants since the secondary simply cannot float back inward under acceleration, it has too much pull on the belt and cant float inward. It will typically only float when you let off/decel.

Talking with Dave at the show...he prefers no float at all. On the Apex we always had some float, and it was easy to set the amt up perfectly. With the winder setup its same as my 12 cat was, and the helix is out further then the hub, and uses this for deflection.

So to do what I want to do.....I went to a proper float(like the apex had) and so I had to use shims for deflection, and then use a 1-3/8" OD washer and a 1.5" OD washer that goes against hub(but fits inside helix) and stock bolt, and a shortened float plug and you may need to use a washer or two depending how much you cut back on float plug, as the stock clutch bolt may be too long and bottom out in Jshaft. Hard to explain it all so I did a video below which might help.

With the setup now...I am set to where the Hurricane bar wants it, and set it up for approx 1.5mm of outward float only, and this is at idle or anywhere on the shift.

Video below trying to explain this....lol

Dan

Large secondary shims for deflection(between sheaves)

View attachment 142632

View attachment 142633

View attachment 142634

2mm total seems good for new ultimax deflection

View attachment 142636

View attachment 142637

View attachment 142655

7mm of original float plug showing(to hub) after lowered offset to 57mm(float plug needs to be shortened)

View attachment 142638

Both OSP & BOP belt adjusters are cutout so hub floats MUCH further outward once into the shift compared to stock flat washer

View attachment 142640

Smaller washers(1-3/8''min to 1.5" max OD)which fit inside of helix bushing.

View attachment 142642

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,868

- Reaction score

- 2,717

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

So now that I used the hurricane offset tool and removed 3mm that makes my new BOP adjuster useless??

Great ...

No, You just need to remove washers accordingly that go between the sleeve and adjuster. I originally provided 4 washers. Feel free to call me if you need help.

saskattakman

Expert

Did you talk to yamaha about this because I talked to the yamaha tech at the Toronto show and he said machining the secondary is unheard of the dealer should fix this under warranty you should be able to line your clutches up from factory

I totally agree with you that this should be fixed under warranty but for the time it takes to load a sled up and take to dealer then try to explain what's going on. then you get the deer in headlights look and we'll it's within specs..much easier to spend $20 get it machined and have pleasure in fixing it yourself rather then having some money wrenching in ot

Fast

TY 4 Stroke Guru

- Joined

- Sep 25, 2018

- Messages

- 996

- Reaction score

- 228

- Points

- 488

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

Dan does the belt run to the top of the primary or is there room to machine in a little more overdrive like the apexAs I said, the spec is LOWER and so mine needed machining. We have all been round and round, and I decided to try Hurricane bar spec this season.

Winderallday!

VIP Member

- Joined

- Dec 4, 2007

- Messages

- 588

- Reaction score

- 167

- Points

- 1,058

- Location

- SW, Ontario

- Country

- Canada

- Snowmobile

- 2018 Sidewinder DX

Regarding BOP coolant hose protectors:The way these fit, there is no movement at all....Its not touching the coolant runner anywhere but around the fins and with the perfect fitment it cannot rub. Its the tunnel where I did not want it wearing against up top. These are lightweight alum.

Very well made and fit up, just installed mine on the weekend.

Maybe it was just my sled, but there was a fair amount of silicone sealant squeezed down around the right hand side coolant hose/clamp area, which would not allow the protector to seat up properly, so I had to scrape/cut away the excess so it would fit up parallel to the tunnel.

Suggest fit up be checked prior to installation to make sure.

Cheers.

Fast

TY 4 Stroke Guru

- Joined

- Sep 25, 2018

- Messages

- 996

- Reaction score

- 228

- Points

- 488

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

Hey Dan, any thoughts on the overdrive question have you ever checked to see if the belt runs to top of primary? what are you running for belt clearance on the primary?As I said, the spec is LOWER and so mine needed machining. We have all been round and round, and I decided to try Hurricane bar spec this season.

Fast

TY 4 Stroke Guru

- Joined

- Sep 25, 2018

- Messages

- 996

- Reaction score

- 228

- Points

- 488

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

Good point, I'm getting my track changed before I bring my new sled home and will ask the dealer to set mine to 58.1mm and see what he says when I pick it up. If they say they set it to that I will know when I get it home and check it and will post the resultsI totally agree with you that this should be fixed under warranty but for the time it takes to load a sled up and take to dealer then try to explain what's going on. then you get the deer in headlights look and we'll it's within specs..much easier to spend $20 get it machined and have pleasure in fixing it yourself rather then having some money wrenching in ot

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

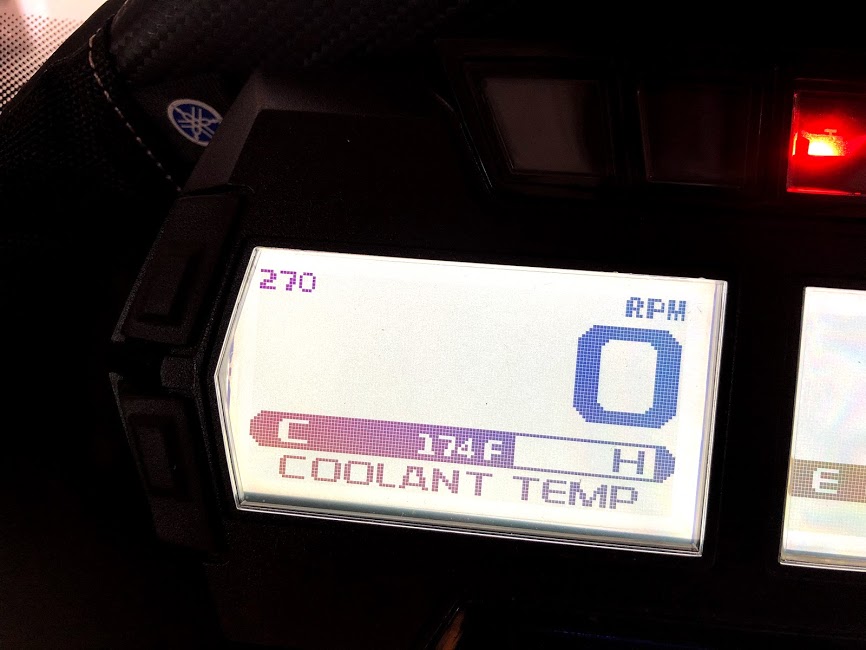

Cluster Flash

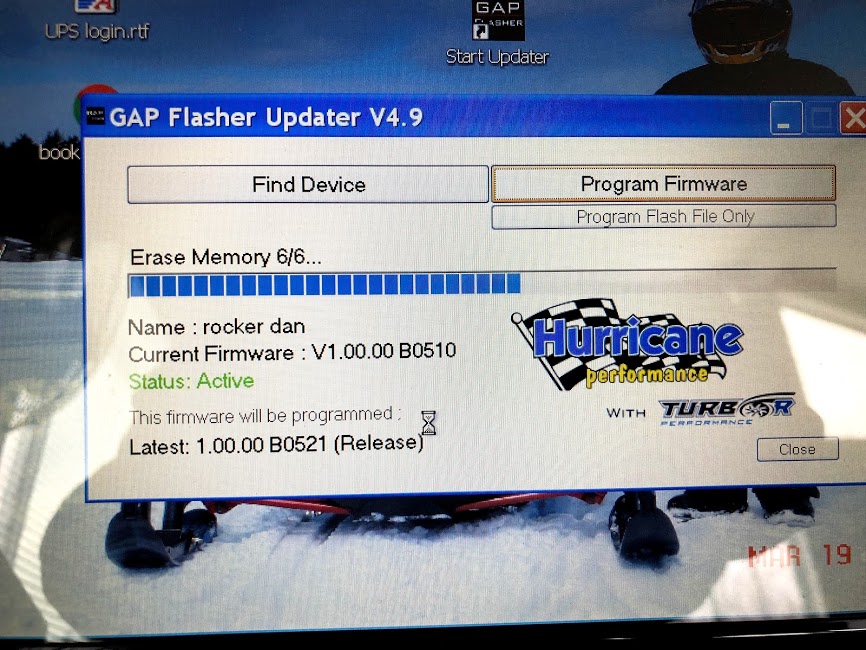

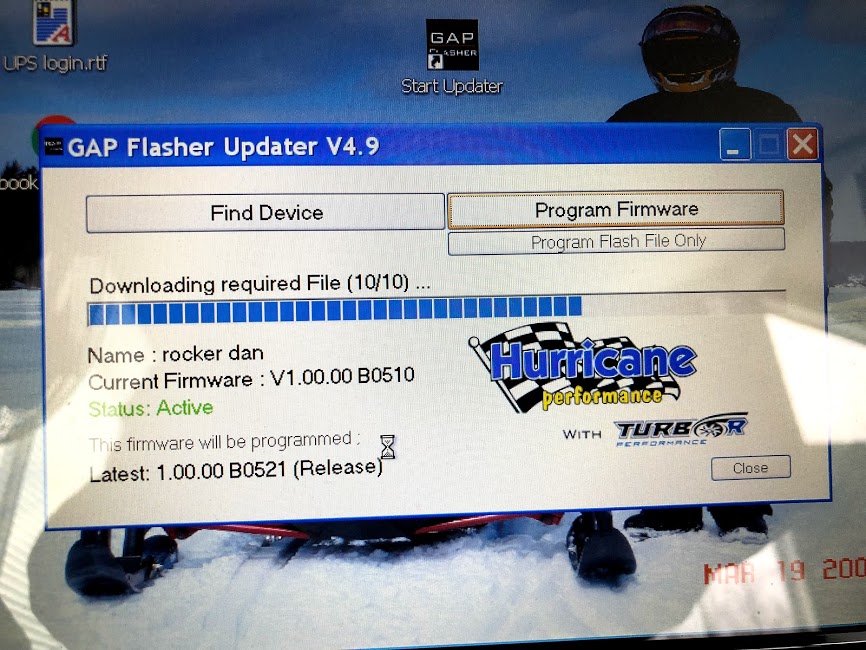

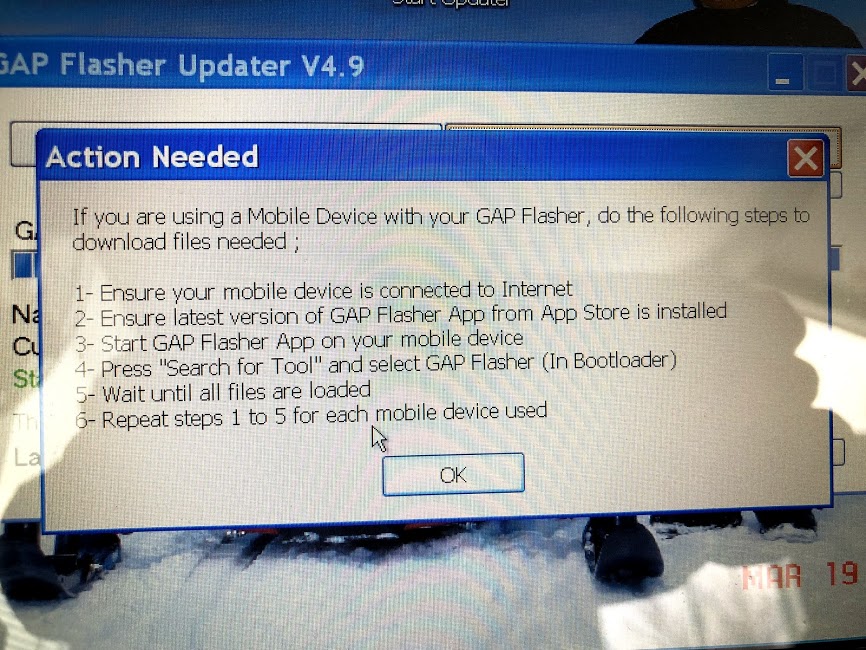

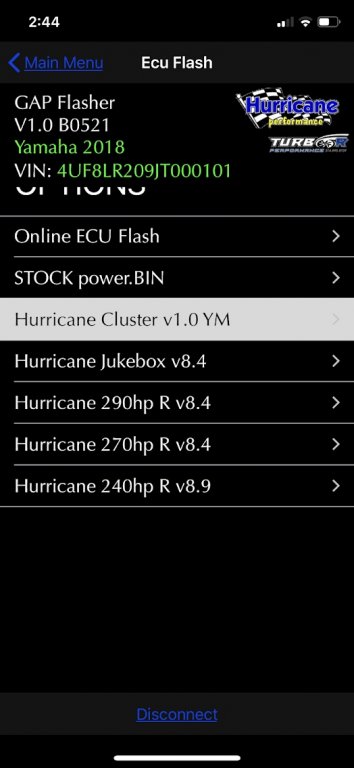

Got the new cluster flash installed today. Very cool for sure. GAP has this tech down pat, super easy to flash these sleds for anyone now.

The Cluster Flash allows for Horsepower changes using the top left button on the factor gauge cluster with just one press. The Horsepower map is displayed in the top left window. I also have the optional handlebar button('Flash to Pass') for HP changes at speeds without letting go of the handlebars.

Also the turbo BOOST is on the factory gauge too....you can move the boost PSI to 3 different locations on the stock gauge which vary in size. Very cool stuff from GAP and Hurricane performance.

Dan

Got the new cluster flash installed today. Very cool for sure. GAP has this tech down pat, super easy to flash these sleds for anyone now.

The Cluster Flash allows for Horsepower changes using the top left button on the factor gauge cluster with just one press. The Horsepower map is displayed in the top left window. I also have the optional handlebar button('Flash to Pass') for HP changes at speeds without letting go of the handlebars.

Also the turbo BOOST is on the factory gauge too....you can move the boost PSI to 3 different locations on the stock gauge which vary in size. Very cool stuff from GAP and Hurricane performance.

Dan

Last edited:

Dash flash is so cool and useful!

Dan since you replaced the Stubshaft with Hurricane how has the alignment been effected?

Dan since you replaced the Stubshaft with Hurricane how has the alignment been effected?

Similar threads

- Replies

- 22

- Views

- 41K

- Replies

- 4

- Views

- 33K

- Replies

- 25

- Views

- 51K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.