Nikolai

TY 4 Stroke God

So here is what I have figured out so far. I want the ability to use the correct Fox shocks down the road which have a collapsed length of 10.8” so I made another strut with holes at 10.75”.

When turning the spindle outward, it will bottom out on the a-arm. There is less swing on the steering arm this way then turning the other way. So no matter what, this is the limiting factor and my steering arm only needs to swing this far.

This is far as the steering arm needs to go. This is with the spindle hitting the a-arm at full compression.

My issue now is at full extension. My tie rod hits the a-arm mount before the steering arm gets over far enough. I will either have to notch into the mount and keep geometry 100% factory or raise the steering arm a little. I’m leaning towards notching the mount.

When turning the spindle outward, it will bottom out on the a-arm. There is less swing on the steering arm this way then turning the other way. So no matter what, this is the limiting factor and my steering arm only needs to swing this far.

This is far as the steering arm needs to go. This is with the spindle hitting the a-arm at full compression.

My issue now is at full extension. My tie rod hits the a-arm mount before the steering arm gets over far enough. I will either have to notch into the mount and keep geometry 100% factory or raise the steering arm a little. I’m leaning towards notching the mount.

Last edited:

RAMSOMAIR

TY 4 Stroke God

Raise the mount on a bushing.

Nikolai

TY 4 Stroke God

I would need to raise the steering arm 0.140”, I’m not sure what affect that would have on steering geometry and if it would be noticeable.

With a 0.140” washer added the tie rod just clears with the steering arm at max turn.

With a 0.140” washer added the tie rod just clears with the steering arm at max turn.

Do you really have to limit yourself to straight rods since you have some metal bending capacity? BOP uses bends in their MPS.

Nikolai

TY 4 Stroke God

No I did not but I had bent tie rods on my last build and wasn’t a fan.

After thinking about it last night every solution I could come up with seemed more complicated, time consuming and heavier then just cutting out the tubes and redoing them. Took me about 2 hours but I got both 1” tubes out and the welds ground smooth. It’s not all bad, the tubes were in the way of the nuts before so I had to weld turned down nuts to the frame which I wasn’t a fan of. After I redo the tubes I’ll have all the tie rod clearance I need and can use regular nuts on the bolts.

Going to put the front suspension back on and figure out the tube location then put it in the jig before welding.

After thinking about it last night every solution I could come up with seemed more complicated, time consuming and heavier then just cutting out the tubes and redoing them. Took me about 2 hours but I got both 1” tubes out and the welds ground smooth. It’s not all bad, the tubes were in the way of the nuts before so I had to weld turned down nuts to the frame which I wasn’t a fan of. After I redo the tubes I’ll have all the tie rod clearance I need and can use regular nuts on the bolts.

Going to put the front suspension back on and figure out the tube location then put it in the jig before welding.

Brotherdan

Expert

- Joined

- Sep 8, 2017

- Messages

- 361

- Age

- 52

- Location

- Belmont,maine

- Country

- USA

- Snowmobile

- 2011 apex xtx blue, starr suspension,gytr front shocks,camso 1.5 track cut down, snowtrackers work in process,2003 rx1er originally 121 converted to 136"monoshock 2 ck136 rear suspension with clicker vector ltx shock,muffin works tunnel extension, seat concepts(wrp) seat,apex hooked handlebars converted to all underhood wiring,8"lake effect billet aluminum riser,gytr frontshocks,yamaheater hand warmer kit,rocks ridelite,rocks power supply, rocks heated bag,, tunnel braces,blue skid plate,garmin gps, aggressive snowtrackers on apex single keel skis,rollerski ski wheel kit,108 warthog studs&blue studboy backers,pioneer wheel lowering kit, dupont slides, 4th wheel kit,yamaha saddle, tank& windshield bags, powermadd led handguards, bar mount mirror kit, apex radiator& electric fan added, apex rear cooler,autometer temp guage, apex new style large diameter drive shaft with extroverts machined for chaincase,thunder products clutching,1987 enticer 340ltr 2100miles,1984 enticer 340,1996 wolverine 350,big wheel kit,winch,racks,k&n,full skidplates

No better time to fix it right, otherwise it’s going to drive you crazy, after you get it all together & its not to your satisfaction( I know it would me)kudos for taking the extra time to get it right, you will be much happier & can proceed to the next step,besides for us that weld its just more practiceNo I did not but I had bent tie rods on my last build and wasn’t a fan.

After thinking about it last night every solution I could come up with seemed more complicated, time consuming and heavier then just cutting out the tubes and redoing them. Took me about 2 hours but I got both 1” tubes out and the welds ground smooth. It’s not all bad, the tubes were in the way of the nuts before so I had to weld turned down nuts to the frame which I wasn’t a fan of. After I redo the tubes I’ll have all the tie rod clearance I need and can use regular nuts on the bolts.

View attachment 167959

View attachment 167960

Going to put the front suspension back on and figure out the tube location then put it in the jig before welding.

Nikolai

TY 4 Stroke God

I agree, it’s frustrating because redoing something like that is 2-3 nights in the shop after kids go to bed but I will be happier with the end result and will have it all figured out if I build another.

Since my new tubes will tie in further back I decided to reinforce the lower tube/a-arm mount with a piece of 1” tube. With that done I will reinstall suspension and fit the upright tubes.

Since my new tubes will tie in further back I decided to reinforce the lower tube/a-arm mount with a piece of 1” tube. With that done I will reinstall suspension and fit the upright tubes.

Nikolai

TY 4 Stroke God

Got the front suspension back on and ran into another hiccup.

Alignment is fairly close and upper rod ends are about where they should be. Also pulled the thick washer back out from below the steering arm so it’s in factory location. So right now it should be 100% factory geometry.

Have about 2 degrees of negative camber that I can’t really do anything about. The rod ends are threaded in 1.5x shank diameter which is usually the minimum for a rod end and that would add more caster as well. I haven’t ridden in forever but aren’t skis usually flat with the ground or is it normal for them to angle in a bit?

Did my best to run thru the center of ball joint and rod end, caster is about 29.5 degrees. From what I have read these models were suppose to be 27 degrees and the difference could just be how my chassis is sitting on the table. Seems close enough.

Steering this way the tie rod clears the a-arm but hits the steel bracket.

When I steer this way the tie rod clears the steel bracket but hits the a-arm.

I’m not really sure what’s going on. If the factory parts aren’t very accurate or my jig was off. I was expecting the front end to go easier but you can’t adjust camber without changing caster, seems odd as every other brand lets you adjust camber. I’m also not sure why the one tie rod is lower than the other.

For the sake of riding I think I’m going to install an additional washer under the tie rod end to clear the a-arm. Adding an .080 washer is enough for the tie rod to adequately clear the a-arm and I can’t imagine that being enough to have a noticeable affect on bump steer.

Long read so to sum it up

1. Is 2 degrees negative camber and skis tilting in normal?

2. Can anyone confirm 27 degrees caster is factory spec?

3. Thoughts on adding additional .080 washer below tie rod end to clear a-arm?

Appreciate all the help from everyone.

Alignment is fairly close and upper rod ends are about where they should be. Also pulled the thick washer back out from below the steering arm so it’s in factory location. So right now it should be 100% factory geometry.

Have about 2 degrees of negative camber that I can’t really do anything about. The rod ends are threaded in 1.5x shank diameter which is usually the minimum for a rod end and that would add more caster as well. I haven’t ridden in forever but aren’t skis usually flat with the ground or is it normal for them to angle in a bit?

Did my best to run thru the center of ball joint and rod end, caster is about 29.5 degrees. From what I have read these models were suppose to be 27 degrees and the difference could just be how my chassis is sitting on the table. Seems close enough.

Steering this way the tie rod clears the a-arm but hits the steel bracket.

When I steer this way the tie rod clears the steel bracket but hits the a-arm.

I’m not really sure what’s going on. If the factory parts aren’t very accurate or my jig was off. I was expecting the front end to go easier but you can’t adjust camber without changing caster, seems odd as every other brand lets you adjust camber. I’m also not sure why the one tie rod is lower than the other.

For the sake of riding I think I’m going to install an additional washer under the tie rod end to clear the a-arm. Adding an .080 washer is enough for the tie rod to adequately clear the a-arm and I can’t imagine that being enough to have a noticeable affect on bump steer.

Long read so to sum it up

1. Is 2 degrees negative camber and skis tilting in normal?

2. Can anyone confirm 27 degrees caster is factory spec?

3. Thoughts on adding additional .080 washer below tie rod end to clear a-arm?

Appreciate all the help from everyone.

Last edited:

kinger

VIP Member

I don't have a measurement but the skis splay out when under load of the sled weight, so I think your negative camber with no weight is fine and actually might be perfect.

Try taking those measurements at ride height, rather than full droop.

Werent those shocks almost .100" longer? Thats alot. Like I said on the 36" Front everything is really at the limits.

Nikolai

TY 4 Stroke God

Mine ended up 16.376. Factory spec you posted was 16.33 so mine are .046 longer which apparently makes a difference.

What I’m going to do for now is just run an additional .080 washer under the tie rod end and then clearance my steel bracket.

What I’m going to do for now is just run an additional .080 washer under the tie rod end and then clearance my steel bracket.

Nikolai

TY 4 Stroke God

I have a little ways to go before I will be able to do that but I will measure again when I get to that point. Going to leave it as is for now and not worry about it.Try taking those measurements at ride height, rather than full droop.

Nikolai

TY 4 Stroke God

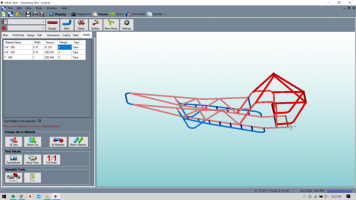

Back to making forward progress. I wanted to get some temporary steering stops put in not only for figuring out tie rod clearance but to make fabricating the stop on the steering post easy.

Put the 10.75 struts back in and placed the stops so the spindle has about a .060 gap from the a-arm.

I tacked one side and then matched the other side to it so steering swing would be guaranteed to be the same both ways.

With stops in place I put the shocks back in and clearanced the steel bracket until the tie rods didn’t contact anymore.

Put the skis on to try and get a more accurate alignment and then double checked tie rod clearance. Figured out where my new 1” tubes need to be so I’ll pull the suspension back off and get the frame in the jig to wrap those up.

Put the 10.75 struts back in and placed the stops so the spindle has about a .060 gap from the a-arm.

I tacked one side and then matched the other side to it so steering swing would be guaranteed to be the same both ways.

With stops in place I put the shocks back in and clearanced the steel bracket until the tie rods didn’t contact anymore.

Put the skis on to try and get a more accurate alignment and then double checked tie rod clearance. Figured out where my new 1” tubes need to be so I’ll pull the suspension back off and get the frame in the jig to wrap those up.

kennyspec

Expert

I did almost my entire tube chassis in 3/4 .035 If i recall correctly my chassis was about 25lbs. That is for the tube only, and i did NOT have the cast pro RMK bulkhead bolted to it when i weighed it.To add to that, I think a completely stock Nytro chassis is 80+ lbs, just the tunnels alone were over 50 lbs with all the steel brackets. With all the hardware the weight is probably closer to 85-90 lbs

And to answer the question about my tunnel, if I did it over again I would probably run a tube straight back from the chaincase to rear bumper instead of bending up like I did and use .049 instead of .058, maybe even 1” x .035, probably keep the lower tube 1” and do the rest of the tunnel in 3/4 x .035. Front half would stay similar aside with minor changes to design.

I’d love to see what you come up with for chassis. I’ve spent hours upon hours googling different sled build for ideas.

Attachments

Similar threads

- Replies

- 4

- Views

- 4K

- Replies

- 32

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.