Kuzzy

Expert

- Joined

- Dec 6, 2020

- Messages

- 442

- Reaction score

- 233

- Points

- 408

- Location

- saskatchewan

- Country

- Canada

- Snowmobile

- 2020 yamaha sidewinder xtx se

2022 STX GT

2017 King Cat M9000

The problem is that it is not just cleanup, the holes aren't tapped all the way through, and often not even deep enough to thread the entire bolt in, I've seen bolts from the factory bottomed out so bad that the end of the bolt is just a nubWow i would think just a thread cleanup would be easy on the tap. Probs should go beter than my hf tap set then.

Is tap a m8x1.25 i assume and or is a thread chaser a differnet tool?

I'm sorry, I honestly don't recall the size, but a tap is the same as chasing threads. Make sure you use some good cutting fluid. Don't try to take too much of a cut, when I say 1/8 of a turn, don't be surprised if it is only 1/16 of a turn or even less. You then have to turn the tap backwards at least a full turn to break the chip. You want to clean the hole often. I swapped between a taper tap and a bottoming tap everytime I pulled the tap to blow out the hole.

If you are nervous at all, pay somebody a couple beers, preferably after they are done running the tap through all the holes lol.

Last edited:

apexgt4life

Expert

Ok still undecided on bolts.

rtx moose

VIP Member

- Joined

- Jul 31, 2014

- Messages

- 1,141

- Reaction score

- 550

- Points

- 1,308

- Location

- WATERTOWN,MN

- Country

- USA

- Snowmobile

- 2017 sidewinder LTX LE,2007 RTX,2000 SRX700

There are different size taps for the same thread. some are a little bigger for pre plating..There all the same pitch diameter at box stores..not saying it matters for this application by any means!The problem is that it is not just cleanup, the holes aren't tapped all the way through, and often not even deep enough to thread the entire bolt in, I've seen bolts from the factory bottomed out so bad that the end of the bolt is just a nub

I'm sorry, I honestly don't recall the size, but a tap is the same as chasing threads. Make sure you use some good cutting fluid. Don't try to take too much of a cut, when I say 1/8 of a turn, don't be surprised if it is only 1/16 of a turn or even less. You then have to turn the tap backwards at least a full turn to break the chip. You want to clean the hole often. I swapped between a taper tap and a bottoming tap everytime I pulled the tap to blow out the hole.

If you are nervous at all, pay somebody a couple beers, preferably after they are done running the tap through all the holes lol.

apexgt4life

Expert

So ss bolts? Why are we putting lock washers on something we cant get apart easily anyway

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,060

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

That's actually kinda' funnySo ss bolts? Why are we putting lock washers on something we cant get apart easily anyway

OR ironic is the word

Todd Beenen

Expert

- Joined

- Feb 16, 2020

- Messages

- 255

- Reaction score

- 176

- Points

- 328

- Location

- Michigan

- Country

- USA

- Snowmobile

- 2020 T-Cat

Check with Tommcat at Tommcat Performance, he sells the bolts for the exhaust.if you want to go that way,and he sells the copper gasket.So ss bolts? Why are we putting lock washers on something we cant get apart easily anyway

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,060

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Once we tapp the holes & put on Nickel Anti-Seize, i guess they could back out.

Let's not forget that Stainless bolts are WEAKER.

So they make stronger SS bolts i think through ARP.

ULMER had some.

I'm not sure if it was mentioned yet, but 2 of the holes don't go all the way through so shorter bolts, or more washers, are required.

Let's not forget that Stainless bolts are WEAKER.

So they make stronger SS bolts i think through ARP.

ULMER had some.

I'm not sure if it was mentioned yet, but 2 of the holes don't go all the way through so shorter bolts, or more washers, are required.

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,060

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Yep, Tomcat had some also

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,298

- Reaction score

- 3,345

- Points

- 1,603

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

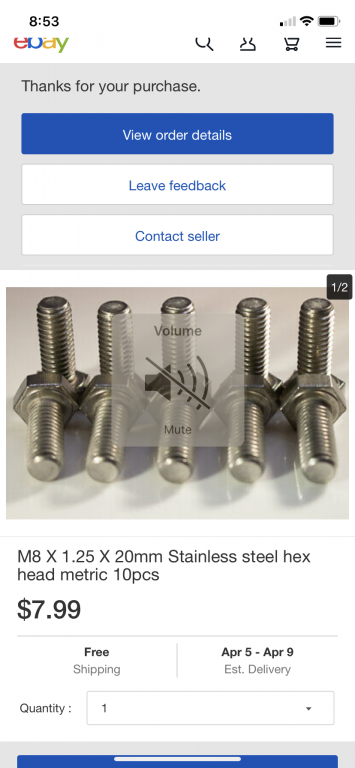

No need for washers. SS BOLTS are fine use plenty of anti seize. Just snug them up good. DO NOT go crazy with torque. I pull mine and replace with new bolts every year. Do not make this complicated these worked with nickel anti. 13k miles. Start your sled and let it run until 170 degrees. Pull

apexgt4life

Expert

Tomcat ones want 27 ft lbs. Stock was 18 which makes me think if these get stuck may be in trouble.Yep, Tomcat had some also

Hmm gor 50 buck i prob just go oem

apexgt4life

Expert

Are you going to factory spec of 18 ftlb which Does not seem like muchNo need for washers. SS BOLTS are fine use plenty of anti seize. Just snug them up good. DO NOT go crazy with torque. I pull mine and replace with new bolts every year. Do not make this complicated these worked with nickel anti. 13k miles. Start your sled and let it run until 170 degrees. Pull View attachment 163142

apexgt4life

Expert

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,298

- Reaction score

- 3,345

- Points

- 1,603

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

Never used torque wrench. I NEVER had to chase the threads. Changed bolts every year. If I had to guess 20 lbs of torque is plenty.Are you going to factory spec of 18 ftlb which Does not seem like much

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,298

- Reaction score

- 3,345

- Points

- 1,603

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

Only possible issue would be the outer diameter of the flange. Couple of the heads are pretty tight clearance wise.

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,060

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

The first time i removed my exhaust i broke a bolt.

Tried everything. It broke.

Luckily i was able to drill a bigger hole & just thru-bolt it.

I chased the rest of the holes & installed store bought SS bolts with some high temp anti-seize. (can't remember what it was)

The next removal, when i realized this chain case needs constant attention, one bolt barely made it out.

The SS bolt was compromised, so i sprung for the hardened SS bolts that are $5 a piece.

Then i bought the highest temp Nickel anti-seize i could, i think 2800 degrees F, and all was OK after that.

Since the chain tension needs to be checked regularly, these bolts now get freshened up plenty.

Just remember that regular SS bolts are WEAKER than average steel bolts.

P.S: Almost impossible to get good torque readings on all 6 bolts so i just use the same wrench & technique on each so they are reasonably close

Tried everything. It broke.

Luckily i was able to drill a bigger hole & just thru-bolt it.

I chased the rest of the holes & installed store bought SS bolts with some high temp anti-seize. (can't remember what it was)

The next removal, when i realized this chain case needs constant attention, one bolt barely made it out.

The SS bolt was compromised, so i sprung for the hardened SS bolts that are $5 a piece.

Then i bought the highest temp Nickel anti-seize i could, i think 2800 degrees F, and all was OK after that.

Since the chain tension needs to be checked regularly, these bolts now get freshened up plenty.

Just remember that regular SS bolts are WEAKER than average steel bolts.

P.S: Almost impossible to get good torque readings on all 6 bolts so i just use the same wrench & technique on each so they are reasonably close

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.