KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,859

- Reaction score

- 6,137

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Carbide “wink wink”

That's what these Rodman bits are is carbide tipped.

Is hole about 1/8in dia? If so will give carbide drill a try.

Yes, 1/8"

I didn't break the bit, just wore the carbide tip right off it. Was going thru like butter till 5.5 mm in, then stopped dead in my tracks. First 5 mm I thought well this is a piece of cake.

Thanks. I will give it a try. Have had a few solid Carbide bits around for awhile. If I break one its no big deal.That's what these Rodman bits are is carbide tipped.

Yes, 1/8"

I didn't break the bit, just wore the carbide tip right off it. Was going thru like butter till 5.5 mm in, then stopped dead in my tracks. First 5 mm I thought well this is a piece of cake.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

I would think with the price of these gears, its cheaper to grab the 1702-395 gear which I was able to get easily from cat, 22 top gear without oil hole, run this for this season....

Then next yr just order the new updated version with oil hole 1702-491 top gear with 22 tooth.

Would be cheaper probably then buying carbide bits no?

I had bought my 22 top gear a couple months ago, so Ill just run it and order the one with oil hole later for next season, or they will be avail in Feb Country cat told me.

Dan

Then next yr just order the new updated version with oil hole 1702-491 top gear with 22 tooth.

Would be cheaper probably then buying carbide bits no?

I had bought my 22 top gear a couple months ago, so Ill just run it and order the one with oil hole later for next season, or they will be avail in Feb Country cat told me.

Dan

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

This has nothing to do with cheap/ or pricing...the stock gears now made by BW are good. Noone has had an issue that Ive seen with exception of that bushing. The gears are not sintered which has muddied up this thread to the point many wont know what our gears are made of.I say don't get cheap with your 15k sled... Get a billet to gear from Taylor or venom... Yep.. Pricey.... but if that cheap gear fails laying the wick... The damage could be catastrophic...

17 onward gears(cat/yam) are all same made by BW and solid(not sintered) and have not shown any issues to my knowledge so lets be sure this is clear. And the 18s it seems they have added oil holes to help with bushing longevity, and this oil hole SHOULD BE drilled through the bushing before installation IMO.

The Scott taylor gear is top of line yes, and likely priced back when we had no other options for a good material, but now it seems a 15 dollar BW gear will do the trick just as well for trail riders.

Dan

**sj**

Lifetime Member

- Joined

- Mar 2, 2004

- Messages

- 6,064

- Reaction score

- 969

- Points

- 1,983

- Location

- southeastern Mich

- Country

- USA

- Snowmobile

- 2019 SRX

This has nothing to do with cheap/ or pricing...the stock gears now made by BW are good. No one has had an issue that Ive seen with exception of that bushing. The gears are not sintered which has muddied up this thread to the point many wont know what our gears are made of.

17 onward gears(cat/yam) are all same made by BW and solid(not sintered) and have not shown any issues to my knowledge so lets be sure this is clear. And the 18s it seems they have added oil holes to help with bushing longevity, and this oil hole SHOULD BE drilled through the bushing before installation IMO.

The Scott taylor gear is top of line yes, and likely priced back when we had no other options for a good material, but now it seems a 15 dollar BW gear will do the trick just as well for trail riders.

Dan

I like to save a buck like the next guy...

When turning up the boost and having really good traction...that little top gear scares me...

remember there is the complex reverse gear portion of the top gear...takes a complex and expensive broach to build.

There's some areas where I chose price over quality......

I just cant fathom a 15-20 dollar gear with a complex broach needed to cut reverse gears into being quality....but i know how you research things fully...and assuming a guy is just a casual trail rider or radar runner..I see what you are saying.

Mike Radlein

Newbie

- Joined

- Nov 5, 2017

- Messages

- 9

- Reaction score

- 0

- Points

- 153

- Location

- Illinois

- Country

- USA

- Snowmobile

- 2017 Yamaha sidewinder ltx-se

anyone have any idea what a 1702-191 is? I ordered a 22tooth gear from the dealer and thats what they gave me

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,859

- Reaction score

- 6,137

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

anyone have any idea what a 1702-191 is? I ordered a 22tooth gear from the dealer and thats what they gave me

DO NOT USE THIS GEAR!

It is sintered, and it's not a Hyvo sprocket, its an old silent chain sprocket. You will eat up the gears and chain if you try and run it.

Mike Radlein

Newbie

- Joined

- Nov 5, 2017

- Messages

- 9

- Reaction score

- 0

- Points

- 153

- Location

- Illinois

- Country

- USA

- Snowmobile

- 2017 Yamaha sidewinder ltx-se

Thanks for the info.DO NOT USE THIS GEAR!

It is sintered, and it's not a Hyvo sprocket, its an old silent chain sprocket. You will eat up the gears and chain if you try and run it.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,859

- Reaction score

- 6,137

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

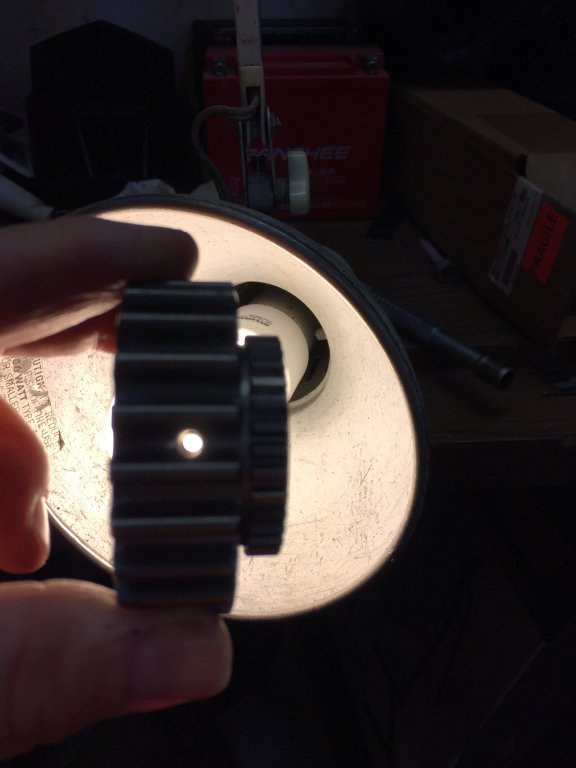

Well not only was I able to get one hole into my 1702-395, I managed to get two holes thru it. When I tried to drill the first hole thru, I thought the bit just flat ground up, but that wasn’t the case, it ended up the carbide tip broke off down in the hole and of course got ground in without me really noticing the tip broke off the bit.

I awoke up the other night thinking there’s no way I can run this gear as it just dawned on me that the tip broke off and there was no way I was going to chance running it. So I was in town yesterday at Ace hardware and figured why not pick up a masonry bit, it’s carbide tipped, why not try drilling thru the opposite side and hit the hole I broke the tip off in.

Well it worked, I went 180 degree off my first hole, and tons of coolant to cool the bit, (thanks to my lovely wife and her 409 spray bottle converted to soap and water) went thru easily and hit my first hole on the opposite side and pushed out the broken carbide tip perfectly!

So the masonry bit works perfect for getting thru hardened steel with lots of coolant (soap and water)! LOl!

I awoke up the other night thinking there’s no way I can run this gear as it just dawned on me that the tip broke off and there was no way I was going to chance running it. So I was in town yesterday at Ace hardware and figured why not pick up a masonry bit, it’s carbide tipped, why not try drilling thru the opposite side and hit the hole I broke the tip off in.

Well it worked, I went 180 degree off my first hole, and tons of coolant to cool the bit, (thanks to my lovely wife and her 409 spray bottle converted to soap and water) went thru easily and hit my first hole on the opposite side and pushed out the broken carbide tip perfectly!

So the masonry bit works perfect for getting thru hardened steel with lots of coolant (soap and water)! LOl!

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,518

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Thanks guys you’ve all done a wonderful job posting your findings on this issue saved me alot of time.

Did you guys see the post in Viper section where a new bushing was sourced from SKF?

Page 17

https://ty4stroke.com/threads/7800m...change-2017-shaft-bearing-info.141330/page-17

Page 17

https://ty4stroke.com/threads/7800m...change-2017-shaft-bearing-info.141330/page-17

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,518

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Ok my new gear has been drilled and new 660 bearing bronze bushing installed. Teflon coating is for non lubricated stuff and can’t take the hammering. This is what they make connecting rod bushings out of so it should hold up much better. I have never seen so many issues with a yamaha sled in my life. Yamaha engineers need to get their heads out off their a$$es.

Ok my new gear has been drilled and new 660 bearing bronze bushing installed. Teflon coating is for non lubricated stuff and can’t take the hammering. This is what they make connecting rod bushings out of so it should hold up much better. I have never seen so many issues with a yamaha sled in my life. Yamaha engineers need to get their heads out off their a$$es.jaydaniels

TY 4 Stroke Junkie

- Joined

- Dec 10, 2008

- Messages

- 654

- Reaction score

- 70

- Points

- 988

- Location

- Bedford NS Canada

- Country

- Canada

- Snowmobile

- 2017 Sidewinder RTX

View attachment 135722 View attachment 135723 Ok my new gear has been drilled and new 660 bearing bronze bushing installed. Teflon coating is for non lubricated stuff and can’t take the hammering. This is what they make connecting rod bushings out of so it should hold up much better. I have never seen so many issues with a yamaha sled in my life. Yamaha engineers need to get their heads out off their a$$es.[/QUO

You mean the Arctic Cat engineers lol.View attachment 135722 View attachment 135723 Ok my new gear has been drilled and new 660 bearing bronze bushing installed. Teflon coating is for non lubricated stuff and can’t take the hammering. This is what they make connecting rod bushings out of so it should hold up much better. I have never seen so many issues with a yamaha sled in my life. Yamaha engineers need to get their heads out off their a$$es.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Agree....I'm not sure an actual YAM engineer ever even sees these sleds unfortunately.

Dan

Dan

Guys I was reading the 18 tech manual and found reference to the oil hole. It is not supposed to be through bushing. According to manual it is supposed to put oil BETWEEN the bushing and gear! Who the heck thought that would work! Anyhow read that and ponder what have we gotten ourselves into.

Similar threads

- Replies

- 27

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.