stohlem

Extreme

- Joined

- Jan 11, 2015

- Messages

- 62

- Reaction score

- 31

- Points

- 843

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX LE, 2014 Apex XTX

- LOCATION

- Illinois

I have a 2017 Sidewinder. After a couple seal leaks, I went with what was suggested by a member a few years ago. The ROV does come apart, so it was suggested to drill a hole through the valve face that's inside. I think I drilled 2 3/32 holes. The reason is if valve seal is iced shut, at least a bit of relief is present until things thaw and the valve functions. I have seen no excessive oil in air box or cooler. I've had it on it's side a couple of times. Just passing it along.

Vmaxkid

Extreme

- Joined

- Oct 16, 2003

- Messages

- 81

- Reaction score

- 38

- Points

- 873

- Location

- Maine

- Country

- USA

- Snowmobile

- 2018 Sidewinder LTX-SE, 2019 Ski-Doo 900T Enduro (not as fun as Sidewinder)

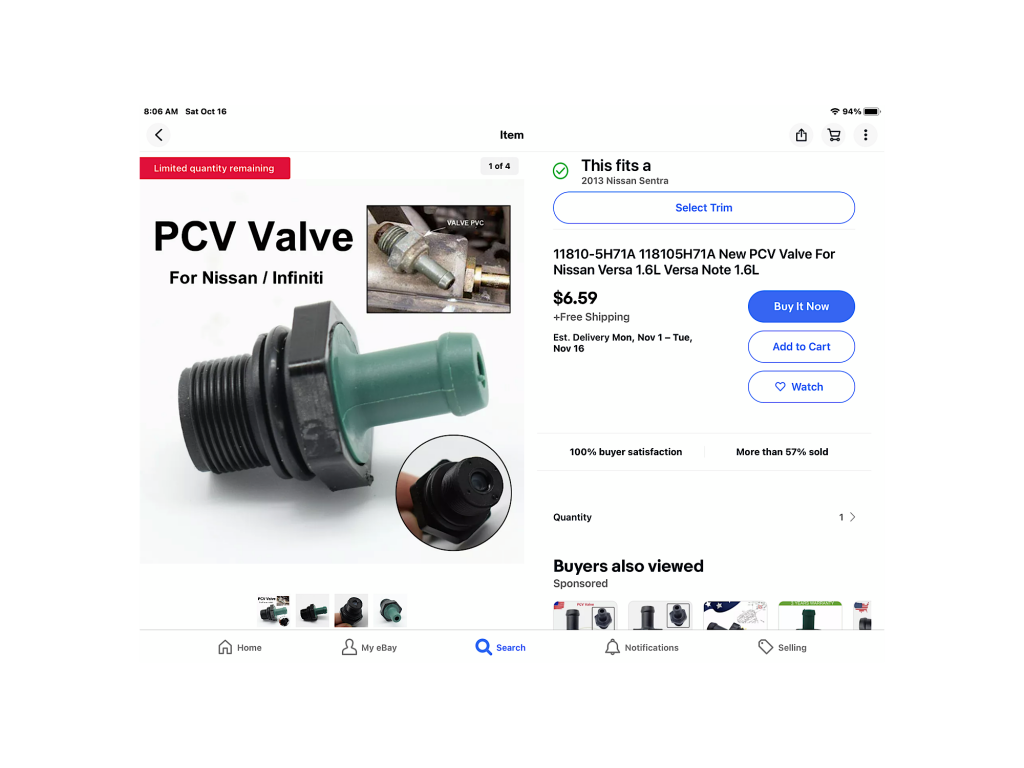

Wouldn’t something as simple as this just work? A PCV Valve that has the same thread and diameter as the oil cap on the oil tank. Screw it on in place of the cap. Add some plastic tubing and loop it up and then down towards the belly pan. If the ROV freezes the oil tank builds pressure and the valve in the PCV body opens allowing pressure to escape. Once the ROV thaws the valve closes when the pressure subsides.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,526

- Reaction score

- 4,186

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Interesting thread. I'd agree with Travis post from long ago which shows pressure building to 55psi. In all my years, I have only seen a roll over valve freeze one time and it was on a 2007 Venture 975. Blew the gasket right out between the cylinder head and valve cover. There had to be an awful lot of pressure to do that

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,876

- Reaction score

- 2,753

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Your logic makes sense, but then there is a second valve that could freeze over so really we are still at risk of pressure build up from a frozen valve.Wouldn’t something as simple as this just work? A PCV Valve that has the same thread and diameter as the oil cap on the oil tank. Screw it on in place of the cap. Add some plastic tubing and loop it up and then down towards the belly pan. If the ROV freezes the oil tank builds pressure and the valve in the PCV body opens allowing pressure to escape. Once the ROV thaws the valve closes when the pressure subsides.

View attachment 163120

Phatboyc

TY 4 Stroke Master

- Joined

- Apr 2, 2007

- Messages

- 1,050

- Reaction score

- 271

- Points

- 1,188

- Location

- Ottawa, Ontario

- Country

- Canada

- Snowmobile

- 2022 Sidewinder

I looked at what Doo did for the 900T. They don't have a ROV and have a PCV on top of the valve cover, like cars, I think. One thing is for sure I couldn't find any post about any freezing issue making a mess with oil tank...

no1b4me

Expert

- Joined

- Dec 31, 2016

- Messages

- 207

- Reaction score

- 235

- Points

- 713

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 ZR9000 Ltd iACT

Man-O-man, you're all splitting hairs on the thread. Not taking anything away from Travis's ingenuity..... But dam just install the KISS principle fix and be done with it...... 99.9% you're riding right side up and on the trails..... You're spending too much time on this teeny weeny issue. A couple feet of heater hose with a gravity loop..... Done all issues solved..... Wear your tether regardless and concerns addressed.

Cheers

Cheers

NYTurbo

TY 4 Stroke God

- Joined

- Sep 26, 2017

- Messages

- 1,578

- Reaction score

- 1,384

- Points

- 1,038

- Location

- Ottawa

- Country

- Canada

- Snowmobile

- Sidewinder

I agree. Also the roll over valve doesn't freeze the moisture builds up in the hose as the ROV keeps the moisture in and the hose freezes. But do not use heater hose oil will eat most types up over timeMan-O-man, you're all splitting hairs on the thread. Not taking anything away from Travis's ingenuity..... But dam just install the KISS principle fix and be done with it...... 99.9% you're riding right side up and on the trails..... You're spending too much time on this teeny weeny issue. A couple feet of heater hose with a gravity loop..... Done all issues solved..... Wear your tether regardless and concerns addressed.

Cheers

no1b4me

Expert

- Joined

- Dec 31, 2016

- Messages

- 207

- Reaction score

- 235

- Points

- 713

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 ZR9000 Ltd iACT

The Gates heater hose 4230S is oil resistant.... Most domestic heater hoses are oil resistant....good point to ensure resistance to oil break down.I agree. Also the roll over valve doesn't freeze the moisture builds up in the hose as the ROV keeps the moisture in and the hose freezes. But do not use heater hose oil will eat most types up over time

Cheers

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,876

- Reaction score

- 2,753

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

If i recall I thought the skidoo motors are wet sump so there is no oil tank.I looked at what Doo did for the 900T. They don't have a ROV and have a PCV on top of the valve cover, like cars, I think. One thing is for sure I couldn't find any post about any freezing issue making a mess with oil tank...

Tank is right on the motor.If i recall I thought the skidoo motors are wet sump so there is no oil tank.

Joseph Levandoski

Expert

- Joined

- Oct 19, 2016

- Messages

- 258

- Reaction score

- 156

- Points

- 458

- Location

- Ellington, CT

- Country

- USA

- Snowmobile

- 2019 Yamaha Sidewinder X-TX LE 141

Tank is right on the motor.

Cannondale27 is correct - all current versions of the 900 ACE (R, 130, non-turbocharged) and 600 ACE motors are dry sump.

Travis -

Is it possible that the ROV bypass kit is permanently bypassing the ROV (because why would it now open if the "air" within the oil sump now has a path of least resistance to the valve cover)? You showed through testing that the oil sump will generate pressure during normal use (and this is what blows the seal when the ROV is frozen closed), so I'm curious if you've inadvertently created a system that's pushing an oil vapor out of the sump to the valve cover, which in turn is already vented from the factory through the breather hose to the backside of the air filter. Which would mean that the ROV bypass is pushing an oily vapor to the intake, which is being burnt by the motor and causing the smoky fume reported by others. Thoughts (from Travis or others)?

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,876

- Reaction score

- 2,753

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

So it appears the smoke from the Sidewinder I had installed a kit on recently was just a fluke. Have been running the sled almost daily since last week and there has not been any smoke. Customer that installed and had smoking removed the kit and is sending it back so I was not able to really do any diagnosing with that sled.

One of my good riding buddies upgraded to a sidewinder this year and he installed the kit on his sled last week. I advised him to run the sled everyday to see if he had any issues and to date he has no smoking issues.

I really dug into the logic of my kit again to see if I overlooked something. I'm essentially doing the same thing that the 05-07 973 motors did. These motors essentially had drop out canister inside the airbox and the accumulated oil drained back into the motor via fitting on the stator cover. They did not have the port on the valve cover. With my kit, the top of the motor is the drop out zone for oil and then the vapor vents out of the oem valve cover vent.

I encourage feedback from anyone that has installed the kit. I'm still putting a hold on shipping anymore kits until I know for sure the kits sold to date are not causing any issue.

One of my good riding buddies upgraded to a sidewinder this year and he installed the kit on his sled last week. I advised him to run the sled everyday to see if he had any issues and to date he has no smoking issues.

I really dug into the logic of my kit again to see if I overlooked something. I'm essentially doing the same thing that the 05-07 973 motors did. These motors essentially had drop out canister inside the airbox and the accumulated oil drained back into the motor via fitting on the stator cover. They did not have the port on the valve cover. With my kit, the top of the motor is the drop out zone for oil and then the vapor vents out of the oem valve cover vent.

I encourage feedback from anyone that has installed the kit. I'm still putting a hold on shipping anymore kits until I know for sure the kits sold to date are not causing any issue.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,876

- Reaction score

- 2,753

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Cannondale27 is correct - all current versions of the 900 ACE (R, 130, non-turbocharged) and 600 ACE motors are dry sump.

Travis -

Is it possible that the ROV bypass kit is permanently bypassing the ROV (because why would it now open if the "air" within the oil sump now has a path of least resistance to the valve cover)? You showed through testing that the oil sump will generate pressure during normal use (and this is what blows the seal when the ROV is frozen closed), so I'm curious if you've inadvertently created a system that's pushing an oil vapor out of the sump to the valve cover, which in turn is already vented from the factory through the breather hose to the backside of the air filter. Which would mean that the ROV bypass is pushing an oily vapor to the intake, which is being burnt by the motor and causing the smoky fume reported by others. Thoughts (from Travis or others)?

The bypass will prevent the ROV from opening as long as pressure in system does not exceed a 1-2 psi. If bypass can't relieve enough pressure than the ROV opens and relieves the additional pressure. Both rollover valve and my bypass force discharge into the intake system. Valve cover vents right into the air filter, while the ROV vents into the intake tube that connects air filter to the turbo intake. Any vapor discharged by either hose essentially in theory gets consumed and burnt.

Phatboyc

TY 4 Stroke Master

- Joined

- Apr 2, 2007

- Messages

- 1,050

- Reaction score

- 271

- Points

- 1,188

- Location

- Ottawa, Ontario

- Country

- Canada

- Snowmobile

- 2022 Sidewinder

Humm to install or not to install...

How many ran the kit last year vs call backs?

How many ran the kit last year vs call backs?

- Joined

- Feb 13, 2017

- Messages

- 186

- Reaction score

- 150

- Points

- 613

- Location

- Amston,CT

- Country

- USA

- Snowmobile

- Renegade 900 ACE,XF 9000 Crosstour,2024 Skidoo Renegade XRS 900R

Thanks for the update Travis, I installed mine over the summer and have not had any smoking issues during several starts .That hose was a challenge to install because of my model sled ,with additional brackets in the rear that had to be removed to shift the gas tank rearward. I also used the BOM packing that was on the valve cover cap, on your modified fitting.All good

Last edited:

Similar threads

- Replies

- 872

- Views

- 157K

- Replies

- 13

- Views

- 8K

- Replies

- 5

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.