KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,847

- Reaction score

- 6,113

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

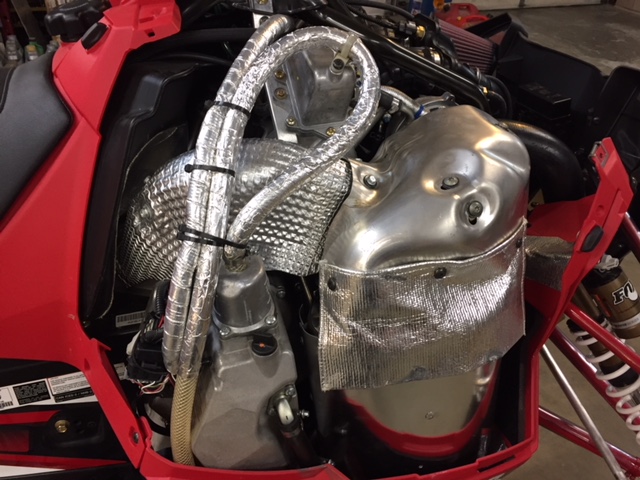

This is what I’ve done to get rid of the problematic valve. Just a hardware store 5/8" ID hose wrapped with foil heat tape, looped it up and over down to under the running board. Let bottom hang and inch or two below the board. You can see how much blowby you have also.

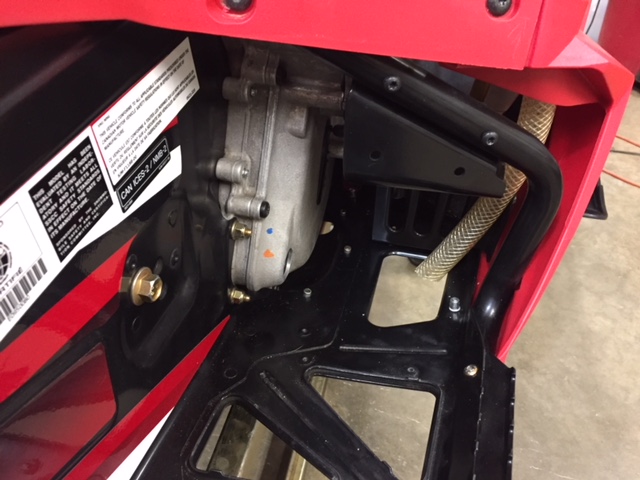

I plugged the line where the stock hose went into the turbo intake with a rubber 3/8" ID cap stretched over the intake turbo tube nipple and clamped.

Now the intake is not getting that blow-by exhaust and no worry of the supposed factory "roll over" valve sticking shut and blowing out the oil tank seal again.

It worked fine on my turbo 1200 Doos for years this exact same way.

I was going to install a 1200 roll over valve but haven’t yet as the space to do so is pretty limited. It’s been over 20 years since I’ve rolled any machine and am not to worried about it not having a valve, for now anyway.

Not telling anyone to get rid of it, but I’m not going to have my oil tank seal blown out on a trip. I’ve already sealed it once as it was leaking.

This is my latest creation as one sled I did last year had a hose kink at the loop. Don't use heater hose either as it is not compatible with oil, make sure to use 5/8" fuel or oil line.

I plugged the line where the stock hose went into the turbo intake with a rubber 3/8" ID cap stretched over the intake turbo tube nipple and clamped.

Now the intake is not getting that blow-by exhaust and no worry of the supposed factory "roll over" valve sticking shut and blowing out the oil tank seal again.

It worked fine on my turbo 1200 Doos for years this exact same way.

I was going to install a 1200 roll over valve but haven’t yet as the space to do so is pretty limited. It’s been over 20 years since I’ve rolled any machine and am not to worried about it not having a valve, for now anyway.

Not telling anyone to get rid of it, but I’m not going to have my oil tank seal blown out on a trip. I’ve already sealed it once as it was leaking.

This is my latest creation as one sled I did last year had a hose kink at the loop. Don't use heater hose either as it is not compatible with oil, make sure to use 5/8" fuel or oil line.

Last edited:

RAMSOMAIR

TY 4 Stroke God

Do go on!

Soldier'spapa

Lifetime Member

- Joined

- Mar 21, 2006

- Messages

- 729

- Reaction score

- 118

- Points

- 908

- Location

- Naperville, IL

- Country

- USA

- Snowmobile

- 2018 Sidewinder Ltx LE 50th Anniversary

Nice! What size tubing? Looks like about 3/4". Did you simply plug the tube going from the RO valve to the intake tract?

RAMSOMAIR

TY 4 Stroke God

Oh, pics just showed up now lol!

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,847

- Reaction score

- 6,113

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Nice! What size tubing? Looks like about 3/4". Did you simply plug the tube going from the RO valve to the intake tract?

5/8" ID tubing.

Yes, Plugged the factory turbo pipe nipple with a 3/8" rubber cap I picked up from the auto store and clamped.

1100saber

Expert

- Joined

- Dec 17, 2016

- Messages

- 324

- Reaction score

- 277

- Points

- 748

- Location

- northern ontario

- Country

- Canada

- Snowmobile

- 2017 Sidewinder LTX-SE

- WEBSITE

- AlliedPerformanceShoppe@outlook.com

- AlliedPerformanceShoppe

5/8" ID tubing.

Yes, Plugged the factory turbo pipe nipple with a 3/8" rubber cap I picked up from the auto store and clamped.

On my list now of things to do. Thanks!

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Mike, nice work.....

I just want to wrap my head around this. Let me know if Im understanding this all correctly.

So sled rolls, and the OIL in oil tank wants to come up that hose, and we have the rollover valve(plunger/spring) which stops the oil from going further.

But if that rollover was not there, the oil would go into the turbo intake track correct?

Where would oil spill out?

Or would it get to the hot turbo, and start on fire instantly?

I know I keep asking same questions, and I really need to just look at my sled under hood and follow the tubes.

Does oil leak out of valve cover anywhere too?

So with your loop/hose setup....NO pressure will build in that oil tank, and any pressure would have to push oil vapors up and over your loop, and then out below your footwell.....do you think that will be alot of oil loss over time though?

Will moisture get into your oil you think?

Dan

I just want to wrap my head around this. Let me know if Im understanding this all correctly.

So sled rolls, and the OIL in oil tank wants to come up that hose, and we have the rollover valve(plunger/spring) which stops the oil from going further.

But if that rollover was not there, the oil would go into the turbo intake track correct?

Where would oil spill out?

Or would it get to the hot turbo, and start on fire instantly?

I know I keep asking same questions, and I really need to just look at my sled under hood and follow the tubes.

Does oil leak out of valve cover anywhere too?

So with your loop/hose setup....NO pressure will build in that oil tank, and any pressure would have to push oil vapors up and over your loop, and then out below your footwell.....do you think that will be alot of oil loss over time though?

Will moisture get into your oil you think?

Dan

fourload

TY 4 Stroke Master

Great write up. Thanks Mike.

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Reaction score

- 1,437

- Points

- 958

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

I see you took it right from the top of the oil tank. Could you take a pic where you plugged the other side? Thanks Mike.

Shagnos

TY 4 Stroke Junkie

- Joined

- Jan 23, 2007

- Messages

- 714

- Reaction score

- 422

- Points

- 1,088

- Location

- Slowville mi

- Country

- USA

- Snowmobile

- Sidewinder

Why even remove the valve? Just cap off the nipple that the tank hose went to and route the new tank hose like Mike did.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

What would happen if we just cut 2 coils off the little spring against the plunger in rollover valve.

Why doesnt someone just make a proper damn gasket seal for this darn tank....why is it even a 2 piece tank anyway....grrrr

lol

Why doesnt someone just make a proper damn gasket seal for this darn tank....why is it even a 2 piece tank anyway....grrrr

lol

SaskAttack

Expert

- Joined

- Jan 4, 2006

- Messages

- 304

- Reaction score

- 136

- Points

- 1,078

- Location

- Corning,SK.

- Country

- Canada

- Snowmobile

- 17 Sidewinder XTX-SE

- LOCATION

- Corning, SK. Canada

Is it the valve itself or hose that actually freezes and causes the problem?

theewarrior

Expert

So will this fix the oil problem in the intercooler and air filter?This is what I’ve done to get rid of the problematic valve. Just a hardware store 5/8" ID hose wrapped with foil heat tape, looped it up and over down to under the running board. Let bottom hang and inch or two below the board. You can see how much blowby you have also.

I plugged the line where the stock hose went into the turbo intake with a rubber 3/8" ID cap stretched over the intake turbo tube nipple and clamped.

Now the intake is not getting that blow-by exhaust and no worry of the supposed factory "roll over" valve sticking shut and blowing out the oil tank seal again.

It worked fine on my turbo 1200 Doos for years this exact same way.

I was going to install a 1200 roll over valve but haven’t yet as the space to do so is pretty limited. It’s been over 20 years since I’ve rolled any machine and am not to worried about it not having a valve, for now anyway.

Not telling anyone to get rid of it, but I’m not going to have my oil tank seal blown out on a trip. I’ve already sealed it once as it was leaking.

View attachment 135444

View attachment 135445

This is a real roll over valve from a 1200 Rotax I had planed to use, but space is tight and I may or may not put it in down the road. I'm not to worried about rolling over anyway. The old Suzuki 1100 turbo never had a roll over valve either...

View attachment 135446

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,847

- Reaction score

- 6,113

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Mike, nice work.....

I just want to wrap my head around this. Let me know if Im understanding this all correctly.

So sled rolls, and the OIL in oil tank wants to come up that hose, and we have the rollover valve(plunger/spring) which stops the oil from going further.

Correct.

But if that rollover was not there, the oil would go into the turbo intake track correct?

Correct.

Where would oil spill out?

Into the intake tube just prior to the turbo on the stock setup.

In my setup in the picture, out the bottom of the hose under the footwell.

However, if the sled is completely upside down, its not going to leak out as the line outlet would be higher than the tank itself.

Or would it get to the hot turbo, and start on fire instantly?

Maybe on the stock setup if it got to the turbo and ignited, but that would be a longshot. Anything is possible however.

I know I keep asking same questions, and I really need to just look at my sled under hood and follow the tubes.

Does oil leak out of valve cover anywhere too?

There is a line from the valve cover going to the airbox, or in my case the cold air intake. I'm not certain, but I think it also has a popoff or pvc valve on it too. I can't see where it has ever vented any oil on mine, but when I took my stock airbox off this fall, I could see the pool of oil in the intake tube from the line coming from the stock roll over valve. That's another reason I wanted to do away with having it run back into the intake. I don't want oil in the intake.

So with your loop/hose setup....NO pressure will build in that oil tank, and any pressure would have to push oil vapors up and over your loop, and then out below your footwell.....

Correct, there will be NO air pressure whatsoever in the oil tank.

do you think that will be alot of oil loss over time though?

No more oil going out there than stock anyways. Same or even less perhaps than stock.

Will moisture get into your oil you think?

No. there will always be positive pressure when running from the blow-by building in the oil tank. You will always see vapor coming from the hose outward, never going in, unless you sink it perhaps. In which case you'd have the same problems anyway.

Dan

I just want to wrap my head around this. Let me know if Im understanding this all correctly.

So sled rolls, and the OIL in oil tank wants to come up that hose, and we have the rollover valve(plunger/spring) which stops the oil from going further.

Correct.

But if that rollover was not there, the oil would go into the turbo intake track correct?

Correct.

Where would oil spill out?

Into the intake tube just prior to the turbo on the stock setup.

In my setup in the picture, out the bottom of the hose under the footwell.

However, if the sled is completely upside down, its not going to leak out as the line outlet would be higher than the tank itself.

Or would it get to the hot turbo, and start on fire instantly?

Maybe on the stock setup if it got to the turbo and ignited, but that would be a longshot. Anything is possible however.

I know I keep asking same questions, and I really need to just look at my sled under hood and follow the tubes.

Does oil leak out of valve cover anywhere too?

There is a line from the valve cover going to the airbox, or in my case the cold air intake. I'm not certain, but I think it also has a popoff or pvc valve on it too. I can't see where it has ever vented any oil on mine, but when I took my stock airbox off this fall, I could see the pool of oil in the intake tube from the line coming from the stock roll over valve. That's another reason I wanted to do away with having it run back into the intake. I don't want oil in the intake.

So with your loop/hose setup....NO pressure will build in that oil tank, and any pressure would have to push oil vapors up and over your loop, and then out below your footwell.....

Correct, there will be NO air pressure whatsoever in the oil tank.

do you think that will be alot of oil loss over time though?

No more oil going out there than stock anyways. Same or even less perhaps than stock.

Will moisture get into your oil you think?

No. there will always be positive pressure when running from the blow-by building in the oil tank. You will always see vapor coming from the hose outward, never going in, unless you sink it perhaps. In which case you'd have the same problems anyway.

Dan

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,847

- Reaction score

- 6,113

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Is it the valve itself or hose that actually freezes and causes the problem?

The stock valve either sticks shut or freezes shut.

Take the valve off and blow thru it. Even when it works it takes a fair amount of pressure to open it too. Now when it sticks shut, the pressure build up is large and blows out the piz poor seal in the tank. that should have actually had a real o-ring used in it, but its a Cat, not a Yamaha, so Cat just does things differently (poorly) of course.

Similar threads

- Replies

- 0

- Views

- 760

- Replies

- 210

- Views

- 51K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.