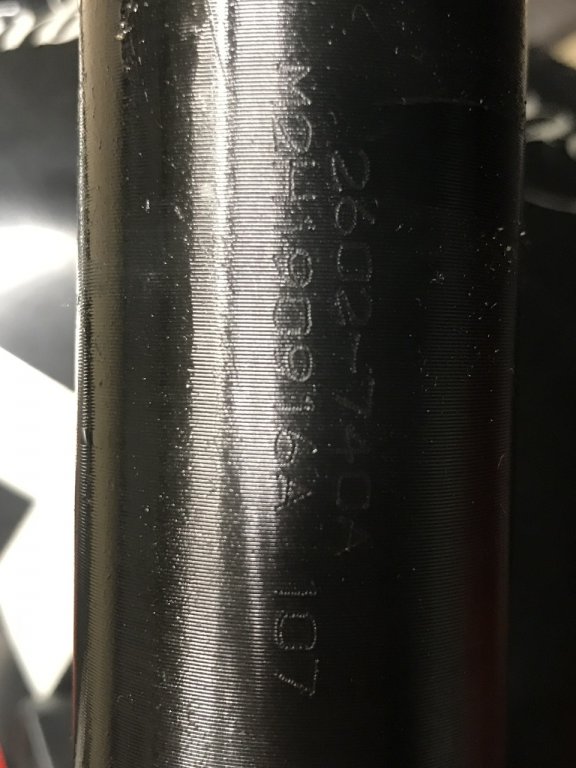

This is from a new introvert shaft delivered spring of 2021. Bearing fit was still sloppy. Not sure hardness.

- Joined

- Feb 13, 2017

- Messages

- 186

- Reaction score

- 150

- Points

- 613

- Location

- Amston,CT

- Country

- USA

- Snowmobile

- Renegade 900 ACE,XF 9000 Crosstour,2024 Skidoo Renegade XRS 900R

That’s progress, (thread #49 ) Fords for Life gets it many can also use there orig shaft,when it is spray welded ,when having the anti- rotation pin installed.$140 plus shipping,and saving the cost of a new shaftYes, drivers and 3 bolt gasket flange included, took mine straight to machine shop for a bearing retaining pin and grove in a new bearing.

Last edited:

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,869

- Reaction score

- 2,720

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Today I got my 22 apart. Put a bearing on the shaft and installed the current driveshaft saver and at 20ft lbs it started to lock down. At 25 i could no longer pull it off by hand. This is right in line with what I was seeing with the 14-20 shafts so I'm having a hard time believing the shaft was indeed hardened. I can mark up the bearing surface on the 22 shaft with a hand file so even if hardness was increased for anti wear, it is still softer than a bearing race.

Based on these findings I'm going to recommend a driveshaft saver for 22+ models.

Even though the expander is still effective on 22, I'm still pursuing my new concept as it provides an easy fix for those that have a worn shaft.

Based on these findings I'm going to recommend a driveshaft saver for 22+ models.

Even though the expander is still effective on 22, I'm still pursuing my new concept as it provides an easy fix for those that have a worn shaft.

Good to know Travis. Is your new design "better" than the wedge for a new, unused 22? Mine is sitting in my trailer with zero miles on it.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,869

- Reaction score

- 2,720

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Good to know Travis. Is your new design "better" than the wedge for a new, unused 22? Mine is sitting in my trailer with zero miles on it.

I am still going to sell the wedge design for those that know they have a good shaft as its easier to install. There really is no uncertainty on a new shaft. The uncertainties arise when one tries to use on a used shaft and doesn't take the time to check shaft for wear. The new concept, wear or no wear will absolutely lock down the bearing. If i recall you already have the wedge for your new 22. If you decide you like my new concept better no problem to send it back to exchange.

Yes, I do have the wedge for the 22. I now have 7k miles on my 2018 with your wedge. If, when I take it apart in July, there is no wear on the shaft, then I will be happy and just use the wedge in the new one.

sxr70001

Lifetime Member

- Joined

- Dec 4, 2010

- Messages

- 1,138

- Reaction score

- 755

- Points

- 1,288

- Location

- Michigan

- Country

- USA

- Snowmobile

- Sidewinder LTX SE

SR Viper RTX SE

What is the acceptable diffference in size between shaft and bearing to use the wedge without building the shaft back up. I will be checking mine this summer.

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,291

- Reaction score

- 3,339

- Points

- 1,603

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

That difference is not a for sure measurement. You can remove the bearing itself from the caliper and install it on your worn shaft and then put wedge on and begin doing torques on a torque wrench and see where it starts to hold the bearing onto shaft. Then maybe increase slightly from that point. I have torqued up to 55 lbs on a severely worn shaft. IMO 60lbs would be max torque. This shaft and wedge issue is not a exact science as far as torque numbers and measurements on worn shafts.. The issue is that these shafts are all over the place for measurements and slip fit for the bearing .. So no exact science here.. IMO 40-55 lbs on torque is a decent range..What is the acceptable diffference in size between shaft and bearing to use the wedge without building the shaft back up. I will be checking mine this summer.

ALSO very important when you install the wedge to make small torques and spin the shaft/track. This allows the wedge to seat(normalize) and helps to prevent the brake assembly from wobbling after assembly.. I like to do about 10 lbs first torque and spin track some and continue every 10 lbs of torque until you reach your desired torque.. So approximately 4-5 different torques with track spin in between each. Guessing we may have a new product from Travis @ BOP that may address new and worn shafts.

sxr70001

Lifetime Member

- Joined

- Dec 4, 2010

- Messages

- 1,138

- Reaction score

- 755

- Points

- 1,288

- Location

- Michigan

- Country

- USA

- Snowmobile

- Sidewinder LTX SE

SR Viper RTX SE

Thanks for the detailed answer. I guess i was hoping for a rule of thumb on what is allowable for that type of interference fit between bearing and shaft from some of you machine shop types. I had metal shop in high school many decades ago and I do have inside and outside calipers and a micrometer. What you are saying makes sense though, basically if the wedge can tighten it up and hold the bearing just go with it. Thanks again.

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,291

- Reaction score

- 3,339

- Points

- 1,603

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

Yup when it starts to hold tight add 10-15 more pounds of torque IMO. send it!Thanks for the detailed answer. I guess i was hoping for a rule of thumb on what is allowable for that type of interference fit between bearing and shaft from some of you machine shop types. I had metal shop in high school many decades ago and I do have inside and outside calipers and a micrometer. What you are saying makes sense though, basically if the wedge can tighten it up and hold the bearing just go with it. Thanks again.

Hoosiersnow

Extreme

- Joined

- May 19, 2015

- Messages

- 79

- Reaction score

- 26

- Points

- 623

- Location

- Indiana

- Country

- USA

- Snowmobile

- 18 cat 600 137

So for someone new at this - is what you are measuring the OD of the shaft vs the ID of the bearing, to check for wear? I haven an 18 Cat 600 with 5K miles on it. I'm going to look at it sometime this summer. I'm assuming the bearing will be needing to be replaced but not sure on the shaft until I look at it of course. I haven't heard as many issues on 600s - perhaps because there aren't as many out there but perhaps less power too. Just speculating.

FrozenTows4

Lifetime Member

- Joined

- Nov 6, 2014

- Messages

- 489

- Reaction score

- 410

- Points

- 1,078

- Location

- Brainerd Minnesota

- Country

- USA

- Snowmobile

- 2014 XF7000 Sold

2017 ZR6000RS

2018 ZR6000 El Tigre

- YOUTUBE

- FrozenTows1

The shaft wears faster than the bearing.So for someone new at this - is what you are measuring the OD of the shaft vs the ID of the bearing, to check for wear? I haven an 18 Cat 600 with 5K miles on it. I'm going to look at it sometime this summer. I'm assuming the bearing will be needing to be replaced but not sure on the shaft until I look at it of course. I haven't heard as many issues on 600s - perhaps because there aren't as many out there but perhaps less power too. Just speculating.

But at that mileage, bearing & shaft will need replacing.

Our 2018 ZR6000 El Tigre at 1500 miles was shot.

The 2017 ZR6000RS at 6500 miles was really shot.

New shafts & bearings on both. Wedge started getting the bearing snug before 20ftlbs.

Torqued to 45ftlbs & called it good. Sleds are now at 5000/13,500 miles. No spinning.

All ProCross spin the caliper side bearing.

Hoosiersnow

Extreme

- Joined

- May 19, 2015

- Messages

- 79

- Reaction score

- 26

- Points

- 623

- Location

- Indiana

- Country

- USA

- Snowmobile

- 18 cat 600 137

Thanks for input. Was hoping that's not the case but it is what it is. I'll try to get to it sooner than later, especially since it's likely I'll need a shaft and I've seen other places they are backordered right now.The shaft wears faster than the bearing.

But at that mileage, bearing & shaft will need replacing.

Our 2018 ZR6000 El Tigre at 1500 miles was shot.

The 2017 ZR6000RS at 6500 miles was really shot.

New shafts & bearings on both. Wedge started getting the bearing snug before 20ftlbs.

Torqued to 45ftlbs & called it good. Sleds are now at 5000/13,500 miles. No spinning.

All ProCross spin the caliper side bearing.

HABS 1

TY 4 Stroke Junkie

- Joined

- Oct 22, 2015

- Messages

- 589

- Reaction score

- 117

- Points

- 728

- Location

- corunna,ontario

- Country

- Canada

- Snowmobile

- 2006 apex gt,136 Hartman ext,dalton clutched,full excel exhaust,yamiheaters,cna pro ex white skis,hid lights,mtx riser,1.5 intense track,etc,etc!---2021 sidewinder xtx se

just wait for bop new design here , that this thred is about, hes makin it to be used on worn shaftsThanks for input. Was hoping that's not the case but it is what it is. I'll try to get to it sooner than later, especially since it's likely I'll need a shaft and I've seen other places they are backordered right now.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,689

- Reaction score

- 2,744

- Points

- 1,053

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

We all know what we mean by this but since Hoosiersnow says he's new, I think it's worth clarifying this to mean the track shaft spins inside the bearing, both when the tracks shaft is being accelerated and decelerated. I think the problem is worse when it's really cold out because the grease in the bearing makes the bearing hard to turn until it warms up.The shaft wears faster than the bearing.

But at that mileage, bearing & shaft will need replacing.

Our 2018 ZR6000 El Tigre at 1500 miles was shot.

The 2017 ZR6000RS at 6500 miles was really shot.

New shafts & bearings on both. Wedge started getting the bearing snug before 20ftlbs.

Torqued to 45ftlbs & called it good. Sleds are now at 5000/13,500 miles. No spinning.

All ProCross spin the caliper side bearing.

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 1

- Views

- 705

- Replies

- 22

- Views

- 3K

- Replies

- 36

- Views

- 7K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.