Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,795

- Reaction score

- 623

- Points

- 1,378

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

You have to understand, even if the tunnel or housing is "off" it will absolutly not wobble. It can ONLY wobble when the bearing is crooked on the shaft or the shaft is bent. Under no other circumstance can the tunnel or housing wobble.

The engineers did not design flex into the chassis or bearing. Nothing else can "break" if the bearing was held tight on the shaft. Ski-Doo does it right with a press fit on the bearing to shaft, and a snug fit in the housing that will not rotate, but it can take more effort to get it apart as the housing needs a bit of effort to get off the bearing.

The Wedge works well to hold things tight when tightened enough and normalized when tightened down so it doesn't cock the bearing on the shaft. The problem (wobble) comes when the bearing is not normalized straight on the shaft. It wont wobble with a good shaft and tightened in stages to nominalize on the shaft and not sit crooked.

Stainless set screws are not hard. You'd be better of with a regular steel set screw. The pin being used for this shaft anti-rotation mod reminds me of a piston ring locating pin, its just way too small. If you insist on using a pin or dowel like that, the old two-stokes used much larger anti-spin dowels in all the crankshaft bearings.

Knapp,

I have my '19 Indy xc apart doing some work on it. The bearing (drive bearing) on that sled seems like it is pressed on similiar to your BRP reference. So i assume when the time comes, the shaft will have to be removed from the sled and the bearing pressed off the shaft using a shop press or using 3 jaw puller. And then press on a new bearing.

Let me ask you this, if there is no flex in the tunnel and there is no need for the bearing to float, then why arent we all fixing them to the shaft via press fit? its just as easy to have a fabricator build the area with a weld and turn it down on a lathe to the right tolerance - (then no wedges, no pins etc).

If the SW had a press fit on the drive bearing, a puller would be needed (templated on the 3 mounting holes of the caliper housing) to drag the bearing and the caliper housing off the shaft (which i have fabricated). No doubt heat would be required. To reinstall - i can only assume the bearing would have to be pressed into the caliper housing first, then using a pipe (hitting only the inner race), drive the housing containing the bearing onto the shaft.

Thoughts?

MS

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,565

- Reaction score

- 3,822

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

I have said this before, it is my belief that the bearing is not locked to the shaft because the bearing is housed in the brake caliper. In this instance, if you have a bearing failure, you could have brake failure. The bearing could spin in the caliper causing the caliper to fail. By not being locked to the shaft, in case of failure or seizure it will still spin on the shaft allowing the brakes to still operate.Let me ask you this, if there is no flex in the tunnel and there is no need for the bearing to float, then why arent we all fixing them to the shaft via press fit?

I could also be dead wrong....

NYTurbo

TY 4 Stroke God

- Joined

- Sep 26, 2017

- Messages

- 1,591

- Reaction score

- 1,390

- Points

- 1,038

- Location

- Ottawa

- Country

- Canada

- Snowmobile

- Sidewinder

YOu could but ideally the bearing gets pressed on the shaft first , the current design doesn’t allow this unless someone re invented the brake caliper housing.Knapp,

I have my '19 Indy xc apart doing some work on it. The bearing (drive bearing) on that sled seems like it is pressed on similiar to your BRP reference. So i assume when the time comes, the shaft will have to be removed from the sled and the bearing pressed off the shaft using a shop press or using 3 jaw puller. And then press on a new bearing.

Let me ask you this, if there is no flex in the tunnel and there is no need for the bearing to float, then why arent we all fixing them to the shaft via press fit? its just as easy to have a fabricator build the area with a weld and turn it down on a lathe to the right tolerance - (then no wedges, no pins etc).

If the SW had a press fit on the drive bearing, a puller would be needed (templated on the 3 mounting holes of the caliper housing) to drag the bearing and the caliper housing off the shaft (which i have fabricated). No doubt heat would be required. To reinstall - i can only assume the bearing would have to be pressed into the caliper housing first, then using a pipe (hitting only the inner race), drive the housing containing the bearing onto the shaft.

Thoughts?

MS

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,974

- Reaction score

- 6,305

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

YOu could but ideally the bearing gets pressed on the shaft first , the current design doesn’t allow this unless someone re invented the brake caliper housing.

Perfectly stated NYTurbo. They could have copied Doo and we wouldn’t even have been talking about this.

Or lock the bearing down with a nut on to a shoulder on the shaft.

The thing is this. The wedge works fine on a shaft that’s sized properly and torqued up well. The problem lies with people not torquing down enough, not properly normalizing the bearing straight on the shaft, or installing on a worn shaft without fitting properly. I torque them up real tight on new shafts from the start and all is well. Upwards of 60 ft lbs using anti seize on the wedge and blue loctite on the bolt after much spinning to normalize on the shaft. Never seen a problem or had the tunnel flexing after an install. I even put a dial indicator on the brake caliper to verify on install to make certain the bearing is not getting cocked on the shaft when installing. I doubt most people take the time or have the indicators do that, but I’m a perfectionist and have the tools.

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,795

- Reaction score

- 623

- Points

- 1,378

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

YOu could but ideally the bearing gets pressed on the shaft first , the current design doesn’t allow this unless someone re invented the brake caliper housing.

Your raise a good point. If you were to drive the bearing in the caliper housing onto the shaft, god knows the force you place on the inner ring, let alone what can happen at the other end in the chain case.

MS

- Joined

- Feb 13, 2017

- Messages

- 186

- Reaction score

- 150

- Points

- 613

- Location

- Amston,CT

- Country

- USA

- Snowmobile

- Renegade 900 ACE,XF 9000 Crosstour,2024 Skidoo Renegade XRS 900R

You will be impressed with what is coming out soonYour raise a good point. If you were to drive the bearing in the caliper housing onto the shaft, god knows the force you place on the inner ring, let alone what can happen at the other end in the chain case.

MS

Last edited:

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,565

- Reaction score

- 3,822

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

From who?You will be impressed with what is coming out soon

- Joined

- Feb 13, 2017

- Messages

- 186

- Reaction score

- 150

- Points

- 613

- Location

- Amston,CT

- Country

- USA

- Snowmobile

- Renegade 900 ACE,XF 9000 Crosstour,2024 Skidoo Renegade XRS 900R

Thread #37 and #131 pictures of new concept coming soon.Barn of partsFrom who?

Last edited:

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,917

- Reaction score

- 2,931

- Points

- 1,113

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

My bearing is pressed on. Shaft was spray welded, then ground on center to produce a .0003-.0005" press fit to bearing. I use BOP puller to remove it (with caliper housing) and a simple press tool to re-install. Press tool is just a 3/8" threaded rod with nuts and washers on both ends. It's made so it comes apart into 3 pieces to be able to insert inside track shaft without interfering with belly pan on either side (have to remove rubber plug with magnets in it on chain case side). I just remove caliper housing with bearing, service it, then just use press tool to re-install.Knapp,

I have my '19 Indy xc apart doing some work on it. The bearing (drive bearing) on that sled seems like it is pressed on similiar to your BRP reference. So i assume when the time comes, the shaft will have to be removed from the sled and the bearing pressed off the shaft using a shop press or using 3 jaw puller. And then press on a new bearing.

Let me ask you this, if there is no flex in the tunnel and there is no need for the bearing to float, then why arent we all fixing them to the shaft via press fit? its just as easy to have a fabricator build the area with a weld and turn it down on a lathe to the right tolerance - (then no wedges, no pins etc).

If the SW had a press fit on the drive bearing, a puller would be needed (templated on the 3 mounting holes of the caliper housing) to drag the bearing and the caliper housing off the shaft (which i have fabricated). No doubt heat would be required. To reinstall - i can only assume the bearing would have to be pressed into the caliper housing first, then using a pipe (hitting only the inner race), drive the housing containing the bearing onto the shaft.

Thoughts?

Attachments

NYTurbo

TY 4 Stroke God

- Joined

- Sep 26, 2017

- Messages

- 1,591

- Reaction score

- 1,390

- Points

- 1,038

- Location

- Ottawa

- Country

- Canada

- Snowmobile

- Sidewinder

How do u know when u have it pressed into the correct position on drive shaft ?

I like this method.

I like this method.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,880

- Reaction score

- 2,765

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Did a complete install with the new concept today on my new 22 and ran it on the stand. Did not run into any issues. Few minor dimensional changes to make but concept works as intended. Maybe next week I will drop a photo of what I've come up with. Will likely release it this summer as I'm sure there are many with worn driveshafts eagerly anticipating a product that does not require them to replace the driveshaft.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,917

- Reaction score

- 2,931

- Points

- 1,113

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

Step on chain case side locates shaft against bearing on that side. I put both bottom gears on to make sure outer circlip goes on. Then press caliper housing on until it just contacts tunnel (not deform it or cause it go be pushed in). I put the 3 bolts in and start to tighten them. I just watch as 3 bolts tighten to make sure tunnel doesn't move. If need be, I can turn my outside nut to press in a bit more. It's very controllable. There is also no side load on bearing.How do u know when u have it pressed into the correct position on drive shaft ?

I like this method.

I've run my sled 3+ years now like this (6,500+ miles). No issues at all. Shaft can't spin in bearing. Bearing is replaceable (no need for machining a slot, etc). Everything looks like new when I serviced it this spring. Pic shows shaft after spray weld and grinding on center to produce a press fit to bearing.

Attachments

swrtxlr

Lifetime Member

- Joined

- Jun 29, 2016

- Messages

- 37

- Reaction score

- 25

- Points

- 743

- Location

- grantsburg

- Country

- USA

- Snowmobile

- 17 sidewinder rtx le

07 apex gt

00 srx olins

99 mountain max fully modded

gp 292

mod 292

You can measure the difference between the ID of the bearing and the OD of the worn shaft and cut a piece of shim stock half the difference and lock it in place. that what I did with mine 7500 miles ago when I added your wedge.Had conversation with senior tech at my dealer last week over what I am working on. He agreed with me that the seal really is not needed. He views it as more of a shield for debris as water gets behind it with ease. My new piece will all but shield the bearing, but I will be able to provide another seal as an option if one prefers to retain the seal.

Another question…

Let’s say I have a worn shaft and have means of installing a bearing that is true and on center. What loctite/liquid bond would one used to “fill in gap” between bearing and worn shaft? Someone suggested green loctite.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,880

- Reaction score

- 2,765

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

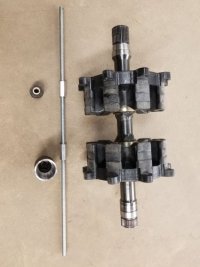

Here's a sneak peak of what's coming!

twyztid

VIP Member

- Joined

- Feb 14, 2011

- Messages

- 1,031

- Reaction score

- 518

- Points

- 1,478

- Location

- Middleville, MI

- Country

- USA

- Snowmobile

- 2025 Sidewinder LTX LE EPS

2017 Sidewinder LTX SE

2012 Apex XTX

2012 RS Vector LTX

- LOCATION

- Middleville, MI

Is that a bearing with an eccentric locking collar?

Similar threads

- Replies

- 5

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.