Nikolai

TY 4 Stroke God

For the guys smarter than me. On the gear end of the Apex jackshaft, a large nut & concave washer secure the upper gear. The Nytro does not have this setup.

Could you do away with the thick washer and nut and use a thin washer and snap ring instead? I’m assuming they use the nut to tighten the gear to the bearing to keep the inner bearing race from spinnin on the shaft.

If you had a thin washer and snap ring up tight against the gear (like tap the snap ring in place with a small punch tight), would that suffice?

And what about replacing the thick steel washer behind the gear with one made from 7075 aluminum?

Could you do away with the thick washer and nut and use a thin washer and snap ring instead? I’m assuming they use the nut to tighten the gear to the bearing to keep the inner bearing race from spinnin on the shaft.

If you had a thin washer and snap ring up tight against the gear (like tap the snap ring in place with a small punch tight), would that suffice?

And what about replacing the thick steel washer behind the gear with one made from 7075 aluminum?

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,421

- Reaction score

- 1,556

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

That nut is tightened to 65 ft-lbs and I think its there to be able to remove the secondary clutch as I always have to have long breaker bars on one side while I tighten the other. I'm guessing a snap ring is a bad idea just trying to replace something that is tightened that much but honestly don't know.

Nikolai

TY 4 Stroke God

I don’t mind removing the jack shaft to remove the clutch if that’s the only reason the nut is there.

I removed the bearing from the case and put it on the jackshaft. The heavy washer & nut are laying down. The thin Nytro concave washer is against the shaft. It would be cleaner and significantly lighter to have the thin washer, snap ring and cut the shaft right after it.

I removed the bearing from the case and put it on the jackshaft. The heavy washer & nut are laying down. The thin Nytro concave washer is against the shaft. It would be cleaner and significantly lighter to have the thin washer, snap ring and cut the shaft right after it.

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,421

- Reaction score

- 1,556

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

That makes sense to me. If its ok on the nytro not sure why it would be different here. Make sure to capture the weight loss, your giving me ideas now! Although if I lost reverse I would want to keep lightening and go belt drive if possible.

Nikolai

TY 4 Stroke God

I’m tracking all the weight. I think I’ll do the snap ring. If it doesn’t work then I’ll get another jack shaft, only one way to find out.

My thinking is that the gear will see minimal lateral load if any at all because the chain should want to keep it aligned since the bottom gear is bolted on. The bearing behind the clutch is pressed into the bearing holder and bearing locked to the jack shaft with 2 set screws so that’s helping keep the jack shaft in place as well. The chassis will be stuff being welded 4130 so there shouldn’t be any chassis flex.

Brake rotor showed up Monday. I’ll post pics as soon as the caliper shows up.

My thinking is that the gear will see minimal lateral load if any at all because the chain should want to keep it aligned since the bottom gear is bolted on. The bearing behind the clutch is pressed into the bearing holder and bearing locked to the jack shaft with 2 set screws so that’s helping keep the jack shaft in place as well. The chassis will be stuff being welded 4130 so there shouldn’t be any chassis flex.

Brake rotor showed up Monday. I’ll post pics as soon as the caliper shows up.

Nikolai

TY 4 Stroke God

I removed the threads from the jackshaft so snap ring it is.

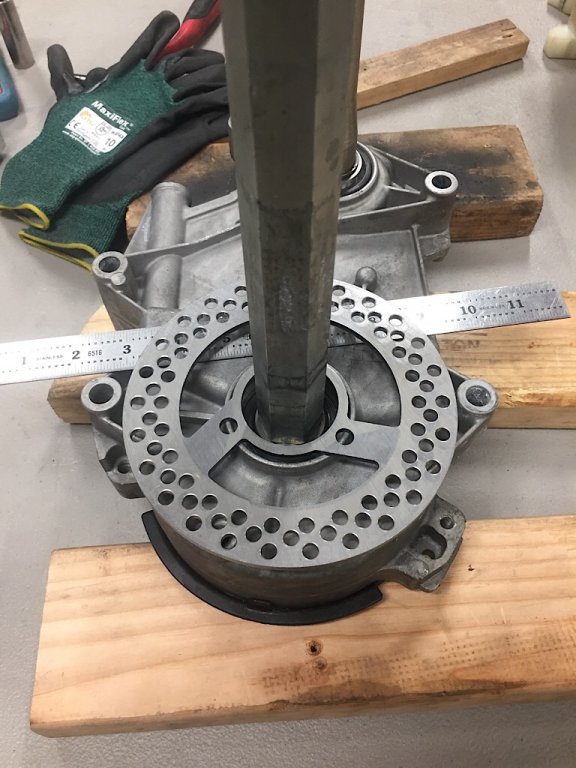

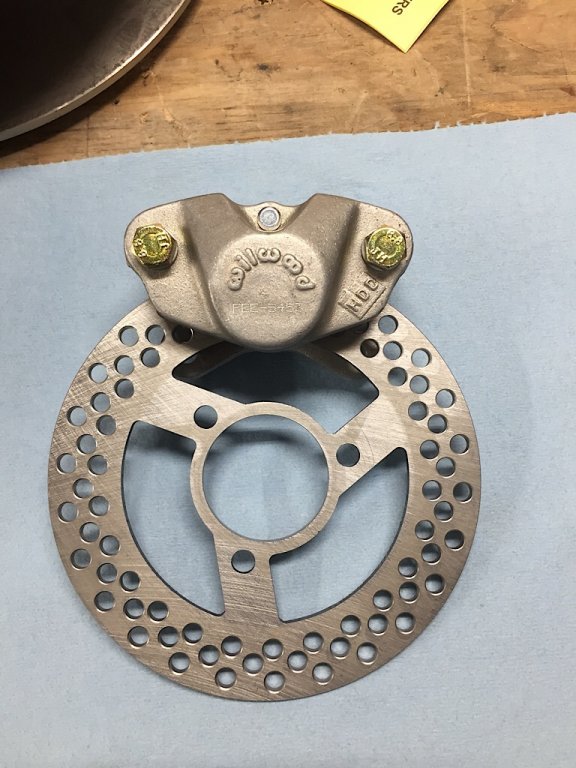

Few pics of the rotor. Same thickness as the Nytro rotor at 5/32 or .156.

Same profile as the chain case so the tube work will be identical on both sides and match nicely.

Few pics of the rotor. Same thickness as the Nytro rotor at 5/32 or .156.

Same profile as the chain case so the tube work will be identical on both sides and match nicely.

Nikolai

TY 4 Stroke God

Finished the cover and sandblasted it at work. It’s not 100% perfect but I was afraid I was getting to picky and would make a mistake. I’m painting it now.

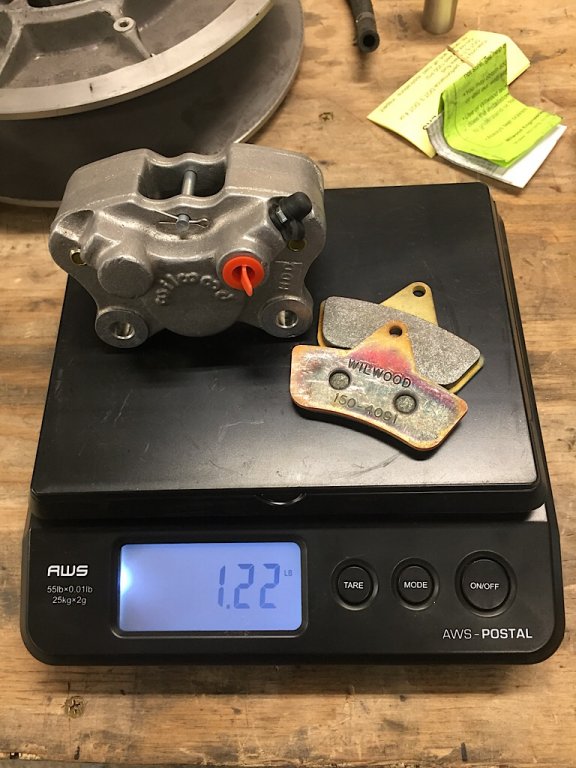

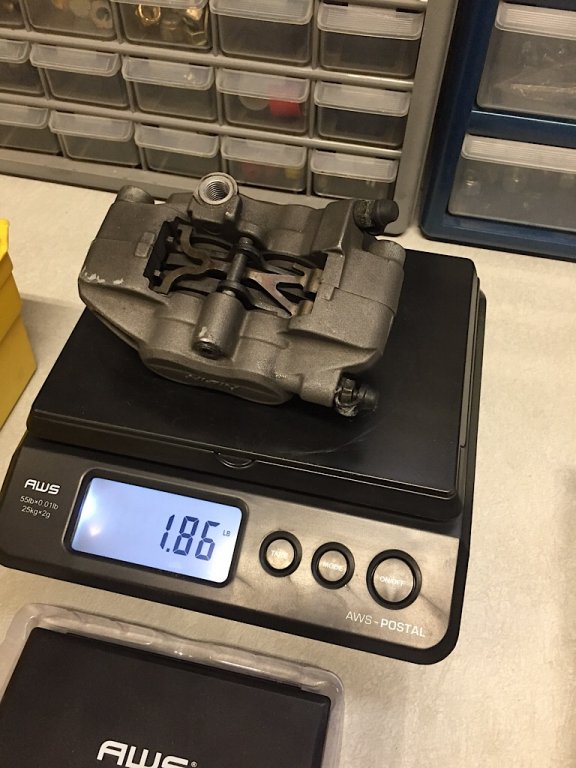

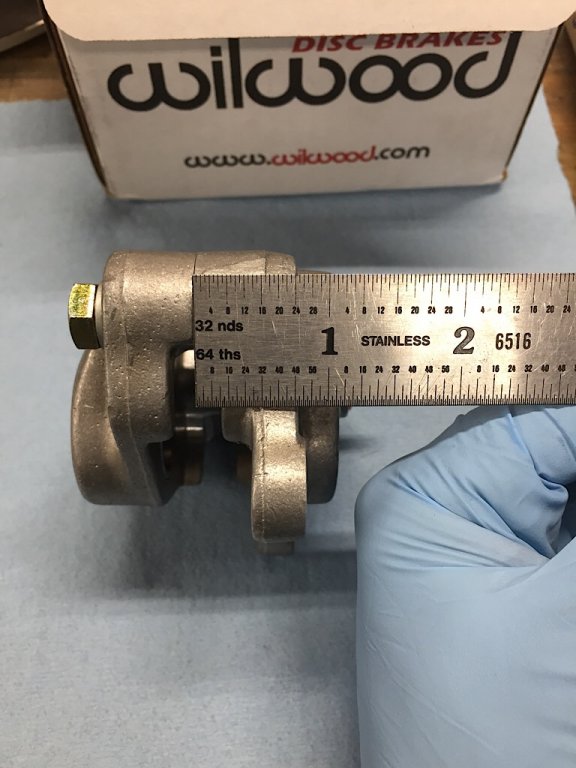

Brake caliper showed up. Wilwood sends 4 pads in a set so that was a nice surprise to get an extra pair.

Apex caliper with pads which is nearly identical to the Nytro caliper.

I’m going to notch out the tunnel so the caliper mounts flush. This should put the rotor 13/16” from the edge of the tunnel skin.

Brake caliper showed up. Wilwood sends 4 pads in a set so that was a nice surprise to get an extra pair.

Apex caliper with pads which is nearly identical to the Nytro caliper.

I’m going to notch out the tunnel so the caliper mounts flush. This should put the rotor 13/16” from the edge of the tunnel skin.

Snowman871

Lifetime Member

- Joined

- Feb 9, 2010

- Messages

- 278

- Reaction score

- 67

- Points

- 1,028

- Location

- Woodville, WI

- Country

- USA

- Snowmobile

- 2024 Polaris Assault 850

Cool build, excited to see how light this ends up!

Hows the new lathe working out?

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,570

- Reaction score

- 4,219

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Interesting thread.

le700

Expert

Wow, nice thread, cool project!!

zx4ever

Expert

- Joined

- Apr 14, 2011

- Messages

- 341

- Reaction score

- 246

- Points

- 1,028

- Location

- Northern BC canada

- Country

- Canada

- Snowmobile

- 08 nytro ty4stroke customized

How did the winter go? Did you make some progress I miss the days when you, sporster Dan and Ricky Coleman just to name a few were always fabbing something and sharing with all of us.

Nikolai

TY 4 Stroke God

Had an awesome summer, non stop fouwheeling. Did 1,100 miles in the RZR in 4 months of camping with the wife and kiddo.

Anyway, I did not forget about the Nyper build. Started making the spacers a few nights ago so I can get a jig of the front end built. The lower a-arm and shock spacers are done.

The oem chassis uses a 12mm bolt for the front of the lower a-arm and a 10mm bolt on the rear. It kills me to use that 12mm bolt and it wouldn’t be needed since my chassis will have a tab on the backside, but I’m already going to have to build custom upper a-arms so I’m leaving the lowers alone. I wanted to use factory lower a-arms, spindles & shocks.

Next task is working on the upper a-arm mounts.

Anyway, I did not forget about the Nyper build. Started making the spacers a few nights ago so I can get a jig of the front end built. The lower a-arm and shock spacers are done.

The oem chassis uses a 12mm bolt for the front of the lower a-arm and a 10mm bolt on the rear. It kills me to use that 12mm bolt and it wouldn’t be needed since my chassis will have a tab on the backside, but I’m already going to have to build custom upper a-arms so I’m leaving the lowers alone. I wanted to use factory lower a-arms, spindles & shocks.

Next task is working on the upper a-arm mounts.

Nikolai

TY 4 Stroke God

Got the spacer made for the upper a-arm so I could get it bolted in place and start getting ideas for the jig.

My upper a-arms will be custom and something similar to this.

It will clear a regular Fox Float without any issues.

My upper a-arms will be custom and something similar to this.

It will clear a regular Fox Float without any issues.

Snowman871

Lifetime Member

- Joined

- Feb 9, 2010

- Messages

- 278

- Reaction score

- 67

- Points

- 1,028

- Location

- Woodville, WI

- Country

- USA

- Snowmobile

- 2024 Polaris Assault 850

Cool to see this build making more progress!

Similar threads

- Replies

- 623

- Views

- 223K

- Replies

- 29

- Views

- 7K

- Replies

- 466

- Views

- 122K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.