DMCTurbo

VIP Member

- Joined

- Nov 12, 2005

- Messages

- 2,829

- Reaction score

- 2,573

- Points

- 1,623

- Location

- Val Caron, Ontario

- Country

- Canada

- Snowmobile

- 2017 Sidewinder XTX LE 137

Yamaha Canada is looking at my sled today so hopefully they do the right thing.

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,298

- Reaction score

- 3,345

- Points

- 1,603

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

Hope it works out for you! And thanks for posting > maybe guys will see this and if have no miles on yet pull them and anti seize or switch them outYamaha Canada is looking at my sled today so hopefully they do the right thing.

- Joined

- Apr 14, 2003

- Messages

- 6,539

- Reaction score

- 3,171

- Points

- 1,983

- Location

- Hessel, Michigan

- Country

- USA

- Snowmobile

- Sidewinder, SR Viper XTX, SR Viper XTX, 2016 Apex XTX and Pro-Line Pro Stock 1000

Thanks NOS PRO. Are you nutting any of them on the back side? I Did not look to see if this was possible? Hope guys can actually get one out with threads still on them to take to the hardware store.. I had one that I had to work on a little.. Lost two threads on a bolt , nothing major, but still

Nothing on the backside, just the same length bolts as factory.

**sj**

Lifetime Member

- Joined

- Mar 2, 2004

- Messages

- 6,064

- Reaction score

- 969

- Points

- 1,983

- Location

- southeastern Mich

- Country

- USA

- Snowmobile

- 2019 SRX

also...on the cat turbo (which I think is the same) Ive used ford manifold studs and nuts....the stud stays in and the nut is on and off...

part number for the stud n811313-2431 and w703902-s306 nut they are coated fyi they are longer though and might be an issue in the tight spots ...just an option

part number for the stud n811313-2431 and w703902-s306 nut they are coated fyi they are longer though and might be an issue in the tight spots ...just an option

Attachments

Kevin

Lifetime Member

- Joined

- Dec 20, 2006

- Messages

- 843

- Reaction score

- 272

- Points

- 1,208

- Location

- Ottawa Canada

- Country

- Canada

- Snowmobile

- Sidewinder

Can someone post a pic of the socket they are using to remove these?

**sj**

Lifetime Member

- Joined

- Mar 2, 2004

- Messages

- 6,064

- Reaction score

- 969

- Points

- 1,983

- Location

- southeastern Mich

- Country

- USA

- Snowmobile

- 2019 SRX

to remove bolts...

take a torx in a socket drive....if you remove the bit from the socket....now you have just the torx bit....take the boxed end of a combination wrench that mates to the bit 5/16? ...take a small piece of electrical tape to the end that going into the boxed end to snug it in...now press the bit into the box...now you have a wrench with a torx bit sticking out of the boxed end..the tape keeps keeps the bit there...

if your bit doesnt grab the stud well...you can dress it on a grinding wheel to bite better

now get a mapp gas torch...not propane...mapp gas burns much hotter....get the stud hot...try to concentrate your heat in the center of the stud.

of course wear thick safe gloves..and now your mini wrench will loosen with ease.

if for whatever reason it doesnt .....or stops and gets a tight spot....reheat...

be patient...heat is your friend...

follow this...remove the bit from the socket after removing the easy ones

75northface

Lifetime Member

- Joined

- Oct 26, 2016

- Messages

- 138

- Reaction score

- 119

- Points

- 313

- Location

- Sudbury, Ontario

- Country

- Canada

- Snowmobile

- - 2017 Sidewinder XTX SE

- 2016 SR Viper LTX DX

- 1997 Mach Z

Can someone post a pic of the socket they are using to remove these?

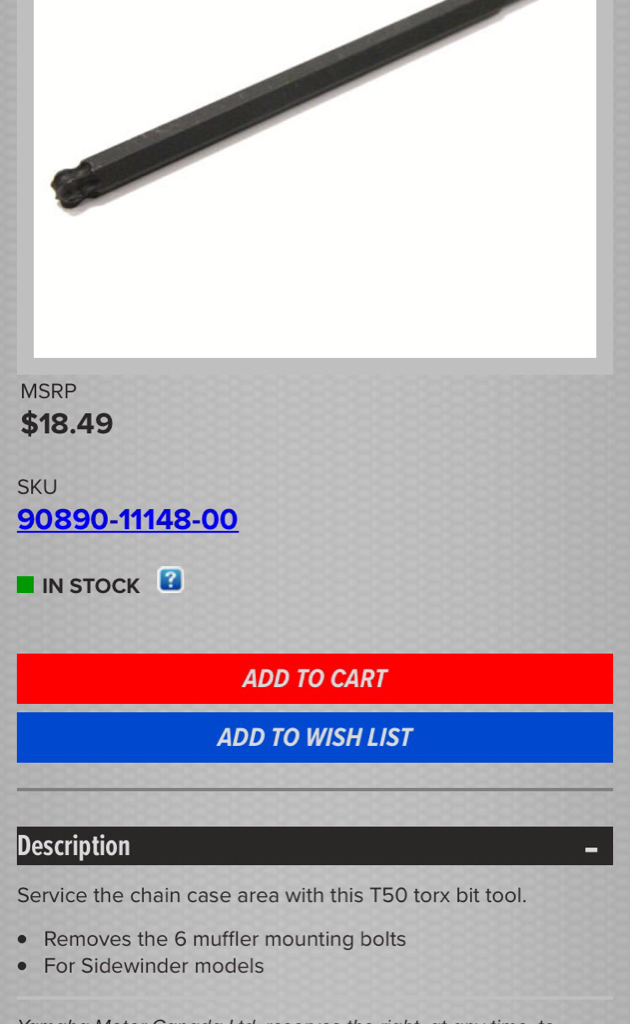

For the stock bolts - I used a T50 ball end torx.

Sent from my iPhone using Tapatalk

75northface

Lifetime Member

- Joined

- Oct 26, 2016

- Messages

- 138

- Reaction score

- 119

- Points

- 313

- Location

- Sudbury, Ontario

- Country

- Canada

- Snowmobile

- - 2017 Sidewinder XTX SE

- 2016 SR Viper LTX DX

- 1997 Mach Z

For the stock bolts - I used a T50 ball end torx.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

**sj**

Lifetime Member

- Joined

- Mar 2, 2004

- Messages

- 6,064

- Reaction score

- 969

- Points

- 1,983

- Location

- southeastern Mich

- Country

- USA

- Snowmobile

- 2019 SRX

all I can say...if you use a ball end...it best be a quality one or you will break a ball in and be really screwed...ask me how I know

Kevin

Lifetime Member

- Joined

- Dec 20, 2006

- Messages

- 843

- Reaction score

- 272

- Points

- 1,208

- Location

- Ottawa Canada

- Country

- Canada

- Snowmobile

- Sidewinder

YIKES!!all I can say...if you use a ball end...it best be a quality one or you will break a ball in and be really screwed...ask me how I know

hooknbook

Veteran

- Joined

- Mar 3, 2016

- Messages

- 48

- Reaction score

- 12

- Points

- 38

- Location

- hartland mi

- Country

- USA

- Snowmobile

- Side winder

- LOCATION

- Bear lk

I just did mine last nite and i had 150 miles on it . It went well no problem with all six bolts. I sprayed some liquid wrench on last nite and this morning took it apart.. a couple were stubborn but i just worked them back and forth. I put antiseize on the bolts before i backed them out. Needed a little heat (map) gas on two..

orangecrush

Extreme

- Joined

- Oct 23, 2012

- Messages

- 50

- Reaction score

- 41

- Points

- 723

- Country

- USA

- Snowmobile

- 2017 Yamaha Sidewinder LTX LE

- LOCATION

- Lino Lakes, MN

Good luck getting that tool from Yamaha! Just checked and back ordered until middle of January!

bleedyamaha

TY 4 Stroke Master

- Joined

- Sep 28, 2013

- Messages

- 1,494

- Reaction score

- 742

- Points

- 1,308

- Location

- Northern Iowa

- Country

- USA

- Snowmobile

- 2017 Yamaha Sidewinder Rtx Le 2012 Yamaha Vector Ltx

Going on my first 150 mile ride Friday and really worried about turbo bolt and 6 muffler bolts. So i rode it in my garage took the panels off and heat shield off to see what i was looking for. Grabbed a 13 mm wrench and gave two bolts a crank and maybe tightened them a1/8 inch. Ther 3 rd bolt was a real pistol to get at without removing the exhaust but i got on it and couldn't budge it. Done with them. So went to my tool box and yes i have a t50 solid socket so i used my extension and 3/8 drive ratchet so i can feel them stripping or turning. Broke 4 loose with no problem but I couldn't get at the other two as i didnt have the proper bit. Now the disclaimer. Don't try this without risk. Took a bit next size smaller out of a socket and put it up in there at a angle with a quarter inch extension and socket and turn very slowly and they broke loose.. just remember i only have 3 miles on my sled. Now if the first 4 bolts didnt break loose as well as they did i would have never tried the other two the way i did. Threw copper antisieze on them and tight all back up. I even put antisieze on the heat shield bolts. Now i can go ride and no i can remove these bolts at a future date. Thank you everyone for bringing this to our attention. Ride on!!!!!

DMCTurbo

VIP Member

- Joined

- Nov 12, 2005

- Messages

- 2,829

- Reaction score

- 2,573

- Points

- 1,623

- Location

- Val Caron, Ontario

- Country

- Canada

- Snowmobile

- 2017 Sidewinder XTX LE 137

So as this is an isolated incident it is apparently my fault. In good faith Yamaha has offered to remove my turbo and I am to bring it to a machine shop at my cost, have it drilled out, return it and Yamaha will re-install it. Not exactly what I was hoping for. A question for the experienced turbo guys, will 5 of the 6 bolts be sufficient if I install hi temp gasket maker on both sides of the stock gasket? I will order a rescue bit and drill out the bolt and broken bit but in the mean time I was planning a trip North next week. Any thoughts? Thanks.

**sj**

Lifetime Member

- Joined

- Mar 2, 2004

- Messages

- 6,064

- Reaction score

- 969

- Points

- 1,983

- Location

- southeastern Mich

- Country

- USA

- Snowmobile

- 2019 SRX

dude...drill it and heat that f*cker up with mapp gas and use an ez outmost big box stores have them....if you use the old z1 gasket with rtv copper you have a chance.....but they leak sometimes even with all the bolts...so ...

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.