Turboflash

TY 4 Stroke God

- Joined

- Mar 18, 2019

- Messages

- 2,443

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

One trip last winter it was -35 degF one night coming home from about 75 miles away. Hard pack trails. By the time all 3 of us got back our studs and tracks were all grinding and rubbing bad due to ice buildup. It was just like SaskAttack posted. So we have to be mindful of checking underneath to see what's going on.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

I never had icing problems like shown in the pictures shown on here.

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,742

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

Ever been to Saskatchewan? Its a totally different kind of cold.

MS

MS

Turboflash

TY 4 Stroke God

- Joined

- Mar 18, 2019

- Messages

- 2,443

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

Ever ridden @ -35 degF?

WinderFab

TY 4 Stroke God

- Joined

- Mar 1, 2009

- Messages

- 1,862

- Age

- 46

- Location

- Woodbridge, ON

- Country

- Canada

- Snowmobile

- 2020 Sidewinder Ltx GT

Yes many times in Northern Ontario.. Coldest was -44 c, took a few hours and all the hair dryers in the motel to get my apex to start lol..

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

I only ride on the South shore of Lake Superior.

It doesnt get that cold here. The coldest i rode my Sidewinder has been is about -25°f.

Most of the time its above 0°f.

It doesnt get that cold here. The coldest i rode my Sidewinder has been is about -25°f.

Most of the time its above 0°f.

SaskAttack

Expert

- Joined

- Jan 4, 2006

- Messages

- 304

- Location

- Corning,SK.

- Country

- Canada

- Snowmobile

- 17 Sidewinder XTX-SE

- LOCATION

- Corning, SK. Canada

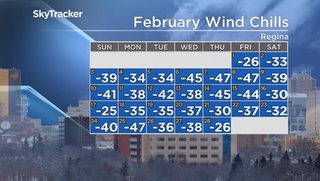

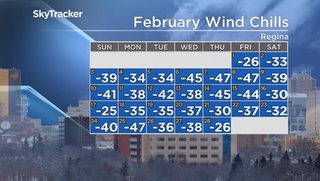

We seem to see a few more "issues" riding around here that some others don't. Can't find straight temp pic but gives you an idea. Tall windshields rule!

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Repaired my tunnel. Its requires alot of disassembly to do the job.

When you guys are replacing your worn out driveshaft take a good look at the top of your tunnel. Push up on the front of the tunnel at the fwd heat exchanger to check this.

I could push my tunnel up by hand creating at least 1/2" of gap to let snow in the engine compartment. Rivets ripped out of the tunnel.

Another issue for blowing belts...

I used hose pinchers and pinched off the coolant hose where it comes thru the tunnel on the left side. That pipe goes up to the filler neck so I didn't loose much coolant.

Here is a couple pics of my repair. One plate on top of the tunnnel.

The bottom I made two plates. One is a filler plate to but up against the lip on the heat exchanger and fill the gap between the tunnel and lip on heat exchanger. Heat exchanger is .080" thick here. The second plate goes over filler plate and lip on heat exchanger sandwiching the top plate, tunnnel, filler plate, and bottom repair plate.

Also installed coolant hose protectors under tunnel.

I am happy with the repair and it really stiffened up the front of the tunnel.

Barn of parts wedgey thing is going in driveshaft when done. New top gear and need to weld my tensioner bolts.

When you guys are replacing your worn out driveshaft take a good look at the top of your tunnel. Push up on the front of the tunnel at the fwd heat exchanger to check this.

I could push my tunnel up by hand creating at least 1/2" of gap to let snow in the engine compartment. Rivets ripped out of the tunnel.

Another issue for blowing belts...

I used hose pinchers and pinched off the coolant hose where it comes thru the tunnel on the left side. That pipe goes up to the filler neck so I didn't loose much coolant.

Here is a couple pics of my repair. One plate on top of the tunnnel.

The bottom I made two plates. One is a filler plate to but up against the lip on the heat exchanger and fill the gap between the tunnel and lip on heat exchanger. Heat exchanger is .080" thick here. The second plate goes over filler plate and lip on heat exchanger sandwiching the top plate, tunnnel, filler plate, and bottom repair plate.

Also installed coolant hose protectors under tunnel.

I am happy with the repair and it really stiffened up the front of the tunnel.

Barn of parts wedgey thing is going in driveshaft when done. New top gear and need to weld my tensioner bolts.

That aint going anywhere! Well done!Repaired my tunnel. Its requires alot of disassembly to do the job.

When you guys are replacing your worn out driveshaft take a good look at the top of your tunnel. Push up on the front of the tunnel at the fwd heat exchanger to check this.

I could push my tunnel up by hand creating at least 1/2" of gap to let snow in the engine compartment. Rivets ripped out of the tunnel.

Another issue for blowing belts...

I used hose pinchers and pinched off the coolant hose where it comes thru the tunnel on the left side. That pipe goes up to the filler neck so I didn't loose much coolant.

View attachment 150999 View attachment 151000

Here is a couple pics of my repair. One plate on top of the tunnnel.

View attachment 151001

The bottom I made two plates. One is a filler plate to but up against the lip on the heat exchanger and fill the gap between the tunnel and lip on heat exchanger. Heat exchanger is .080" thick here. The second plate goes over filler plate and lip on heat exchanger sandwiching the top plate, tunnnel, filler plate, and bottom repair plate.

View attachment 151003

Also installed coolant hose protectors under tunnel.

I am happy with the repair and it really stiffened up the front of the tunnel.

Barn of parts wedgey thing is going in driveshaft when done. New top gear and need to weld my tensioner bolts.

WinderFab

TY 4 Stroke God

- Joined

- Mar 1, 2009

- Messages

- 1,862

- Age

- 46

- Location

- Woodbridge, ON

- Country

- Canada

- Snowmobile

- 2020 Sidewinder Ltx GT

Awesome work.. thanks for the pics..

Hammer70

GRIPNRIP

- Joined

- Sep 6, 2015

- Messages

- 824

- Location

- Niagara, Ontario.

- Country

- Canada

- Snowmobile

- 82SS440/96VMAX/02SRX/08APE/15SRVIPER/17SIDEWINDER

Looks good I don’t think you will have any more issues now.

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,742

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

I had mine apart this summer to place more rivets along the top of the heat exchanger. I know what you mean by a lot of work.

Nice job. Pretty solid now.

MS

Nice job. Pretty solid now.

MS

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,742

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

It funny that you had the lip of the tunnel tear out from the rivets but your louvres didn't look like they got bent/folded down.

The ice on mine flattened that row of louvres. Had to bend them all down

MS

The ice on mine flattened that row of louvres. Had to bend them all down

MS

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

It's a lot of work but I shouldn't have any more issues in that area. Late last winter I started to have belt issue again and now I know why from snow coming in. Below the engine inside the frame would be all ice right up to the top of the frame rails.

Good point. It could be just water freezing in between the exchanger and tunnel expanding enough to loosen rivets. Then flex.It funny that you had the lip of the tunnel tear out from the rivets but your louvres didn't look like they got bent/folded down.

The ice on mine flattened that row of louvres. Had to bend them all down

MS

Similar threads

- Replies

- 21

- Views

- 32K

- Replies

- 29

- Views

- 3K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.