ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,518

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

We've all been waiting and writing about the 'real fix' for a long time. But that needs to come from Yamaha and /or Cat.

They say there’s a fix coming, I got $50 sayin it’s gonna be a different tensioner and possibly a harder/tighter upper bushing. With no sight glass now, you might also see a different amount of oil prescribed for fill level. Nothing we haven’t already discussed and recommend.

People still having issues are doing something different imo.

I helped a local guy who was having issues with bearing failure, he wanted me to come over give my 2 cents. When I set his tension at .125” bolt to tensioner the chain was so loose with the 21t top sprocket that it almost hit the center post when rotated backwards. He was unwilling to allow that kind of slack in the chain. He ended up doing 1 turn out from VERY finger tight and the bolt was still very close, around 035” clearance. He will have premature wear imo, but it will be better than before imo, he was only going 1/2 turn previously.

BOP is working on a fix, I like Travis’s ideas better than Yamaha anyway (they actually work!)

Last edited:

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,484

- Reaction score

- 3,745

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

Isn't it irritating when some asks for advice on a problem they cant fix and dismiss YOU for being wrong?I helped a local guy who was having issues with bearing failure, he wanted me to come over give my 2 cents. When I set his tension at .125” bolt to tensioner the chain was so loose with the 21t top sprocket that it almost hit the center post when rotated backwards. He was unwilling to allow that kind of slack in the chain. He ended up doing 1 turn out from VERY finger tight and the bolt was still very close, around 035” clearance. He will have premature wear imo, but it will be better than before imo, he was only going 1/2 turn previousl

Fast

TY 4 Stroke Master

- Joined

- Sep 25, 2018

- Messages

- 1,015

- Reaction score

- 231

- Points

- 758

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

Who's they ,yamaha or articatThey say there’s a fix coming, I got $50 sayin it’s gonna be a different tensioner and possibly a harder/tighter upper bushing. With no sight glass now, you might also see a different amount of oil prescribed for fill level. Nothing we haven’t already discussed and recommend.

People still having issues are doing something different imo.

I helped a local guy who was having issues with bearing failure, he wanted me to come over give my 2 cents. When I set his tension at .125” bolt to tensioner the chain was so loose with the 21t top sprocket that it almost hit the center post when rotated backwards. He was unwilling to allow that kind of slack in the chain. He ended up doing 1 turn out from VERY finger tight and the bolt was still very close, around 035” clearance. He will have premature wear imo, but it will be better than before imo, he was only going 1/2 turn previously.

BOP is working on a fix, I like Travis’s ideas better than Yamaha anyway (they actually work!)

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,518

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Jarett from Yamaha says it’s happening.

Byam

TY 4 Stroke Guru

- Joined

- Apr 23, 2015

- Messages

- 793

- Reaction score

- 580

- Points

- 1,038

- Location

- En Motoneige

- Country

- Canada

- Snowmobile

- SW2017

custom

Ca

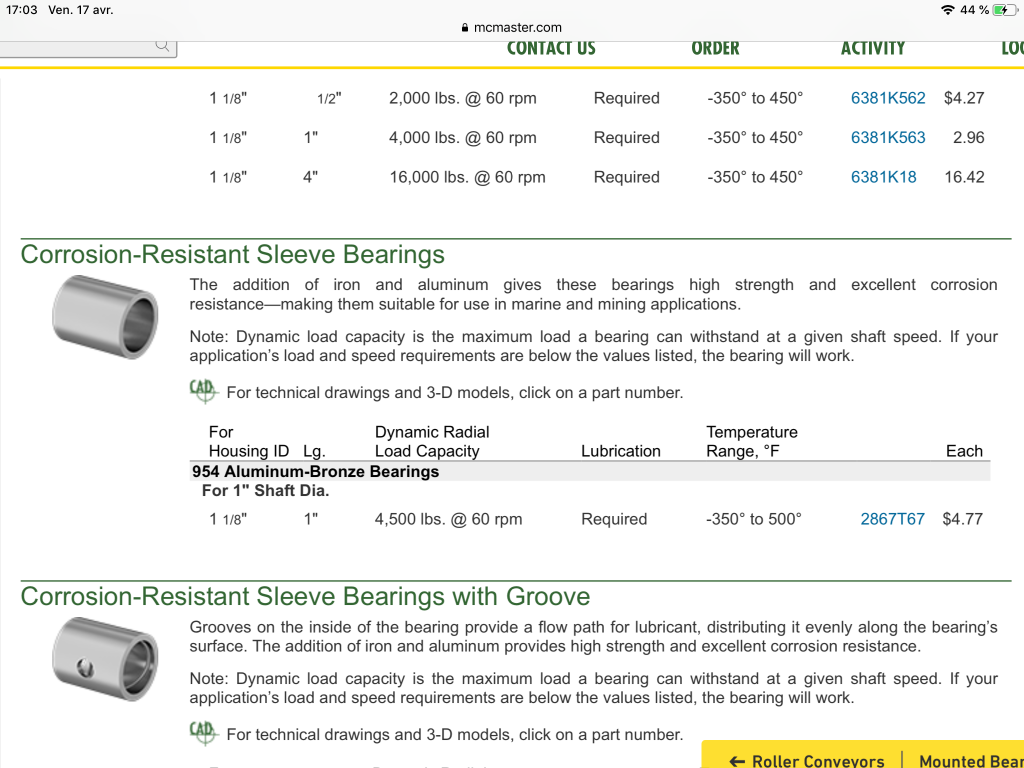

I have this one in my #22 NO OIL hole. 2867t67

Looks new after 1500km

I have did 10 oookm whit stock bushing. Always ~ 1/8 between tensioner and bolt. That’s it.

Inside the chaincase post rubbing? =yes

tensioner grooving through post and need bushing? = yes

Behind upper gear it should be a slug instead of snap ring?=yes

No sight glassThey say there’s a fix coming, I got $50 sayin it’s gonna be a different tensioner and possibly a harder/tighter upper bushing. With no sight glass now, you might also see a different amount of oil prescribed for fill level. Nothing we haven’t already discussed and recommend.

People still having issues are doing something different imo.

I helped a local guy who was having issues with bearing failure, he wanted me to come over give my 2 cents. When I set his tension at .125” bolt to tensioner the chain was so loose with the 21t top sprocket that it almost hit the center post when rotated backwards. He was unwilling to allow that kind of slack in the chain. He ended up doing 1 turn out from VERY finger tight and the bolt was still very close, around 035” clearance. He will have premature wear imo, but it will be better than before imo, he was only going 1/2 turn previously.

BOP is working on a fix, I like Travis’s ideas better than Yamaha anyway (they actually work!)

I have this one in my #22 NO OIL hole. 2867t67

Looks new after 1500km

I have did 10 oookm whit stock bushing. Always ~ 1/8 between tensioner and bolt. That’s it.

Inside the chaincase post rubbing? =yes

tensioner grooving through post and need bushing? = yes

Behind upper gear it should be a slug instead of snap ring?=yes

Last edited:

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,544

- Reaction score

- 4,195

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

I just pressed a bushing into a 17 Cat with 12000 kms on original bushing about an hour ago. About half the teflon gone, but not as bad as some I've seen!No sight glass

View attachment 155057

I have this one in my #22 NO OIL hole. 2867t67

Looks new after 1500km

I have did 10 oookm whit stock bushing. Always ~ 1/8 between tensioner and bolt. That’s it.

Inside the chaincase post rubbing? =yes

tensioner grooving through post and need bushing? = yes

Behind upper gear it should be a slug instead of snap ring?=yes

View attachment 155058

Mototown

TY 4 Stroke Guru

- Joined

- Sep 11, 2018

- Messages

- 871

- Reaction score

- 744

- Points

- 728

- Location

- Ontario

- Country

- Canada

- Snowmobile

- Apex 40 th

Yamaha should just add 20 $ to the oil change kit & add a top gear to the packages . Then this thread would be long gone .... problem solved.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,518

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Ca

No sight glass

View attachment 155057

I have this one in my #22 NO OIL hole. 2867t67

Looks new after 1500km

I have did 10 oookm whit stock bushing. Always ~ 1/8 between tensioner and bolt. That’s it.

Inside the chaincase post rubbing? =yes

tensioner grooving through post and need bushing? = yes

Behind upper gear it should be a slug instead of snap ring?=yes

View attachment 155059

View attachment 155058

That’s the same bushing I’m running, glad to hear it’s working for you! A little harder than the 660 bearing, similar too a soft Ampco bushing.

In order of hardness,

Oilite on the left, 660 middle and aluma bronze on the right.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,518

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Great idea with the spacer/c-clip delete!

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,544

- Reaction score

- 4,195

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Hi Byam, what is the advantage of using a spacer in behind the gear instead of the snap ring?

Byam

TY 4 Stroke Guru

- Joined

- Apr 23, 2015

- Messages

- 793

- Reaction score

- 580

- Points

- 1,038

- Location

- En Motoneige

- Country

- Canada

- Snowmobile

- SW2017

custom

Just preventive, it make the system more reliable for low$$$... this picture is from one of my buddy who's mechanic for a yamaha dealer. He had seen couples snap ring failure, so this is his fix. we could probably use alu brz bushing whit bigger od !Hi Byam, what is the advantage of using a spacer in behind the gear instead of the snap ring?

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,518

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Just preventive, it make the system more reliable for low$$$... this picture is from one of my buddy who's mechanic for a yamaha dealer. He had seen couples snap ring failure, so this is his fix. we could probably use alu brz bushing whit bigger od !

Hey now there’s a great idea! Make some collars 1.25” OD that press onto the driveshaft!

They would need heat treatment tho.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,518

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Pretty easy to bore out a gear for a larger bushing.

Thats what that guy on here did with that big Bronze looking Bushing thats alot of $. I would imagine by more surface area and the support of it against bearing both help the wear.Pretty easy to bore out a gear for a larger bushing.

twyztid

VIP Member

- Joined

- Feb 14, 2011

- Messages

- 1,008

- Reaction score

- 505

- Points

- 1,328

- Location

- Middleville, MI

- Country

- USA

- Snowmobile

- 2025 Sidewinder LTX LE EPS

2017 Sidewinder LTX SE

2012 Apex XTX

2012 RS Vector LTX

- LOCATION

- Middleville, MI

I like the idea of having a channel for oil distribution machined into the bushing...it sure couldn't hurt.

I am starting to wonder if after a long lake or rail bed run we should be putting our sleds in reverse and backing up a bit to rotate the top gear and get some fresh oil in there...might help.

My bushing was obviously pretty dry and chattering on the jackshaft.

View attachment 154976

That is the Teflon that is worn off. Not necessarily from being "dry"

Similar threads

- Replies

- 191

- Views

- 28K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.