Chris Rose

Expert

- Joined

- Jul 29, 2016

- Messages

- 288

- Age

- 70

- Location

- Powassan ONT

- Country

- Canada

- Snowmobile

- 2017 sidewinder stx-DX with TD/Max 16 stock muffler

- WEBSITE

- chrisjrose2018@@gmail.com

I can only say "I told you so" As i figured this roll over junk valve would fail tons in colder weather. I have not run mine for 2000 miles..

Great post KnappAttack!

Some may remember my post from last year > oil leaking on my right foot!

You guys have gone a step further then my original fix.. Great post guys

When I installed the loop on my sled I noticed that when the sled is on the right side the loop is still higher than the oil tank. Oil loss should be minimal.I can only say "I told you so" As i figured this roll over junk valve would fail tons in colder weather. I have not run mine for 2000 miles..

Great post KnappAttack!

Some may remember my post from last year > oil leaking on my right foot!

You guys have gone a step further then my original fix.. Great post guys

If you were really concerned with the oil backing out the loop when the sled on its side just make the loop wider than the tank, as in sweep the loop out to the right side of the tank and vent down the left side. And if you're still concerned just leave it stock and don't touch anything.

Curious as to why this isn’t a problem with other Yamaha 4 strokes like the apex and vector? Do they not have a roll over valve?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Age

- 69

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

They have a solid oil tank that won't blow out the seal.Curious as to why this isn’t a problem with other Yamaha 4 strokes like the apex and vector? Do they not have a roll over valve?

Sent from my iPhone using Tapatalk

They have a solid oil tank that won't blow out the seal.

Gotcha. Thanks for the response

Sent from my iPhone using Tapatalk

jaydaniels

TY 4 Stroke Junkie

- Joined

- Dec 10, 2008

- Messages

- 654

- Location

- Bedford NS Canada

- Country

- Canada

- Snowmobile

- 2017 Sidewinder RTX

They have a solid oil tank that won't blow out the seal.[/

Curious as to why this isn’t a problem with other Yamaha 4 strokes like the apex and vector? Do they not have a roll over valve?

Sent from my iPhone using Tapatalk

Correct, they don’t have a roll over valve. Plus like others said, a solid one piece oil tank.

A full loop of hose will also fill up with water and freeze SJ. There is a lot of water vapor and condensation that comes out of this hose.

DO NOT, repeat , DO NOT TRY AND RUN A FULL LOOP OF HOSE AS IT WILL FREEZE SOLID OVERNIGHT WITH WATER AND BE ICE IN THE AM.

Yep... File that in the just throwing something stupid out there bin lol. Of course moisture will fill in the low part of the loop and create the problem worse than the original problem...kiss. Keep it simple stupid Steve

- Joined

- Nov 29, 2009

- Messages

- 1,230

- Age

- 49

- Location

- sabattus, maine

- Country

- USA

- Snowmobile

- 76 exciter, 87 phazer, 89 bravo, 00 srx x3, 01 srx, 02/04 viper, 06 ape

It was my first thought too, don't feel badYep... File that in the just throwing something stupid out there bin lol. Of course moisture will fill in the low part of the loop and create the problem worse than the original problem...kiss. Keep it simple stupid Steve

actionjack

TY 4 Stroke God

- Joined

- Apr 9, 2005

- Messages

- 2,516

- Location

- Westminster, Maryland

- Website

- www.inspectorjack.com

- Country

- USA

- Snowmobile

- 2017 SideWinder LTX-LE

You are still running this simply completely bypassing the valve?I can only say "I told you so" As i figured this roll over junk valve would fail tons in colder weather. I have not run mine for 2000 miles..

Great post KnappAttack!

Some may remember my post from last year > oil leaking on my right foot!

You guys have gone a step further then my original fix.. Great post guys

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Just a quick update....Ran mine Saturday all day, trails and lakes from tight slow trails to the big high speed trails and then really rolling on the lakes....Saturday was MINUS 33c (27.4 BELOW ZERO Fahrenheit) and even on deeper powder my 3/8" vent tube down below belly pan never could/would freeze. Checked it often at these extreme temps and could feel the warm vented(moist) air pushing out always. This works flawlessly.(Knapp is da'man!)

Sunday was much milder, and obviously worked wonderful at more typical temps too.....So with 250 new miles on the vent tube setup, and 550 miles on the winder total now....All is well. And this engine just keeps getting faster, pulling away harder and faster from the 800 pack then when it had no miles on it. Hard to believe im still all stock tuned. Not for much longer tho.

More I think about this....I could see a tube running higher up, but be sure not to have any area where vapor would collect/freeze as Mike mentioned.....then back down. Same principal a good plumber goes by, to always have a proper level(downward) so water can never get stuck in a pipe.

But for now I'm leaving mine as is, and ready to start to toy with big power!

Thanks again Mike for bringing the goods brother.

Dan

Sunday was much milder, and obviously worked wonderful at more typical temps too.....So with 250 new miles on the vent tube setup, and 550 miles on the winder total now....All is well. And this engine just keeps getting faster, pulling away harder and faster from the 800 pack then when it had no miles on it. Hard to believe im still all stock tuned. Not for much longer tho.

More I think about this....I could see a tube running higher up, but be sure not to have any area where vapor would collect/freeze as Mike mentioned.....then back down. Same principal a good plumber goes by, to always have a proper level(downward) so water can never get stuck in a pipe.

But for now I'm leaving mine as is, and ready to start to toy with big power!

Thanks again Mike for bringing the goods brother.

Dan

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,265

- Age

- 50

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

Yes. Its not perfect as It does allow some moist air into your intake.. Not sure its much more then if your running with the check valve.. Everyone SHOULD do themselves a favor and pull your air filter off and clean it and check for oil/water/hot air mist in the air tract tube.. Simply > pull your filter and take a flash light and shine it down into ir intake tube.. MOST sidewinders will have some water/oil gunk in the low spot in this tube.. CLEAN it out and dry it.. Seems to me the colder the temps you ride in the more junk will be in this tube.. I believe thats why some are blocking this off completely. And running cold air intakes?You are still running this simply completely bypassing the valve?

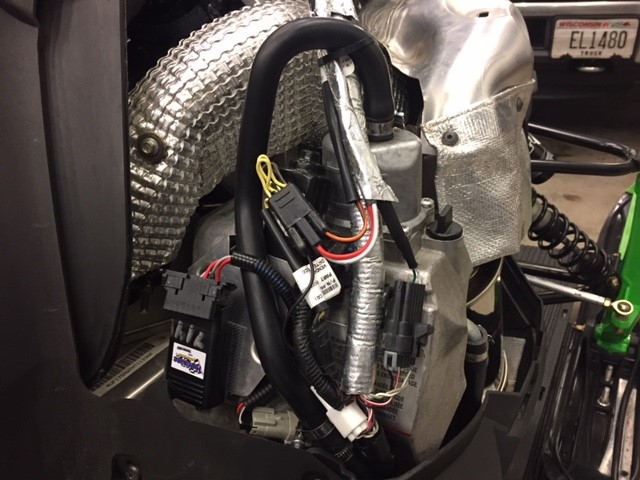

I just finished mine....Used some plumbing items I had here already, and a rubber fuel line.

I just dont want any issues with leaking oil tank seal in these extreme temps...Plenty of vapors coming out this hose as I just tested it. Mine is tad different then Mikes as I left all the stock stuff in place, but same idea and no more pressure in tank.

Thanks Mike for the good imagination on this one, Nice work.

Dan

View attachment 135617 View attachment 135618

again...your attention to detail pays off nicely for me lol

would we agree that since the pressure can never build with this setup the valve should never open and allow the oily mist into the intake tract?

Dan do you think it might be necessary to run heat protection over the hosing?

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Yeah Steve I don't see how the valve would ever be pushed open, since there is NO PRESSURE AT ALL now within the tube.again...your attention to detail pays off nicely for me lol

would we agree that since the pressure can never build with this setup the valve should never open and allow the oily mist into the intake tract?

Dan do you think it might be necessary to run heat protection over the hosing?

I like this alot, I know lots of these sleds end up with lots of oily mess in charge tubes. So we should not have any of that now.

Sure cant hurt....but I went with fuel line, which is same rubber material of the stock hose, and then I ran it further away from hot shroud then stock tube, and sorta have the wrapped wire loom BETWEEN my new hose and the hot shroud. And after two days of riding, it looks perfect, no heat issue.

I think If I looped it higher, I may wrap it entirely, sure wont hurt.

Dan

Never Satisfied

Pro

I took the line from the valve to the intake tube and re-purposed it. This way I won't lose it!

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

That is fantastic! Nice thinking there brother!I took the line from the valve to the intake tube and re-purposed it. This way I won't lose it!View attachment 135733

And thanks for the pic, Im about to be installing my flasher,

Dan

Similar threads

- Replies

- 210

- Views

- 46K

- Replies

- 13

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.