Nikolai

TY 4 Stroke God

Ugh, so I think I might have screwed myself a little on the tie rods. I didn’t occur to me until today to check, but I’m afraid my tie rod is going to hit the .035 tube. Looking at pics online, the tie rods appear to come out perpendicular to the centerline of the chassis and my .035 tubes will push them forward a little.

I was going to hold off ordering a-arms until the sled was done but I think I’m going to order the AC 36” front end kit which comes with a-arms, spindles & tie rods. At least then I can figure out what to do with the tie rods and modify the frame work if needed. I can also use the front end to mock up a straight post and see how it affects steering.

I was going to hold off ordering a-arms until the sled was done but I think I’m going to order the AC 36” front end kit which comes with a-arms, spindles & tie rods. At least then I can figure out what to do with the tie rods and modify the frame work if needed. I can also use the front end to mock up a straight post and see how it affects steering.

Well that's a bummer. Looks like the tie rods will move even further into the space occupied by the .035 tube as you turn the steering post. Will you move the .035 tubes back to make room or leave the tubes where they are and change your tie-rod positioning?

Nikolai

TY 4 Stroke God

I’m not entirely sure what I’m going to do. My inner tie rod came in and just playing around with the positioning, simply moving the inner rod end 1/2” closer to the steering pivot creates a lot of extra clearance to the .035 tube. If I can get away with doing something like that then I probably will. That shouldn’t change much geometry wise. I don’t want to move the .035 tube if I don’t have to, I would prefer that it stay tied in the 1/8” plate where it’s at now.

I’m waiting to hear back from the dealer on a price for the kit. I don’t want to worry too much until I actually have the suspension bolted on.

I’m waiting to hear back from the dealer on a price for the kit. I don’t want to worry too much until I actually have the suspension bolted on.

Nikolai

TY 4 Stroke God

I’ve been getting my RZR ready for summer and never got a 36” front end kit. I decided to just weld it the way it is and I will notch & reinforce the 1” .035 down tubes to clear the tie rods whenever that day comes.

Should have the rear down tubes done tomorrow maybe and then I’ll work on the motor mount tube.

Should have the rear down tubes done tomorrow maybe and then I’ll work on the motor mount tube.

Nikolai

TY 4 Stroke God

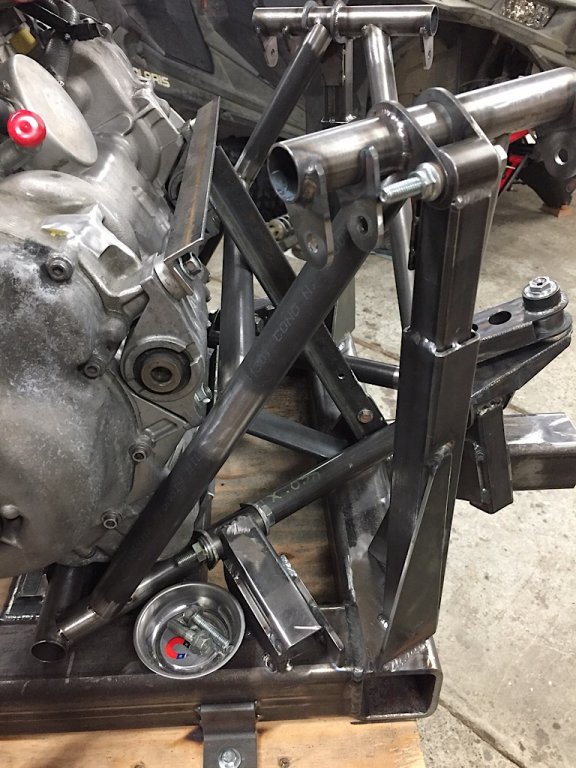

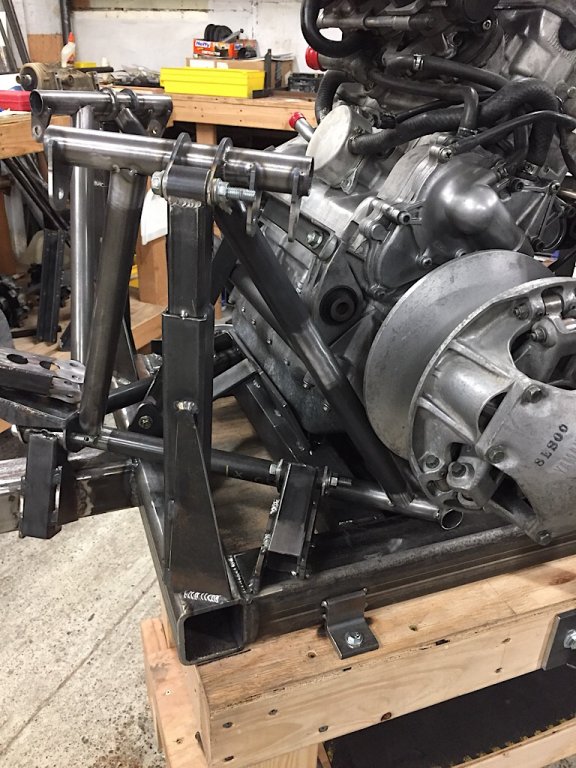

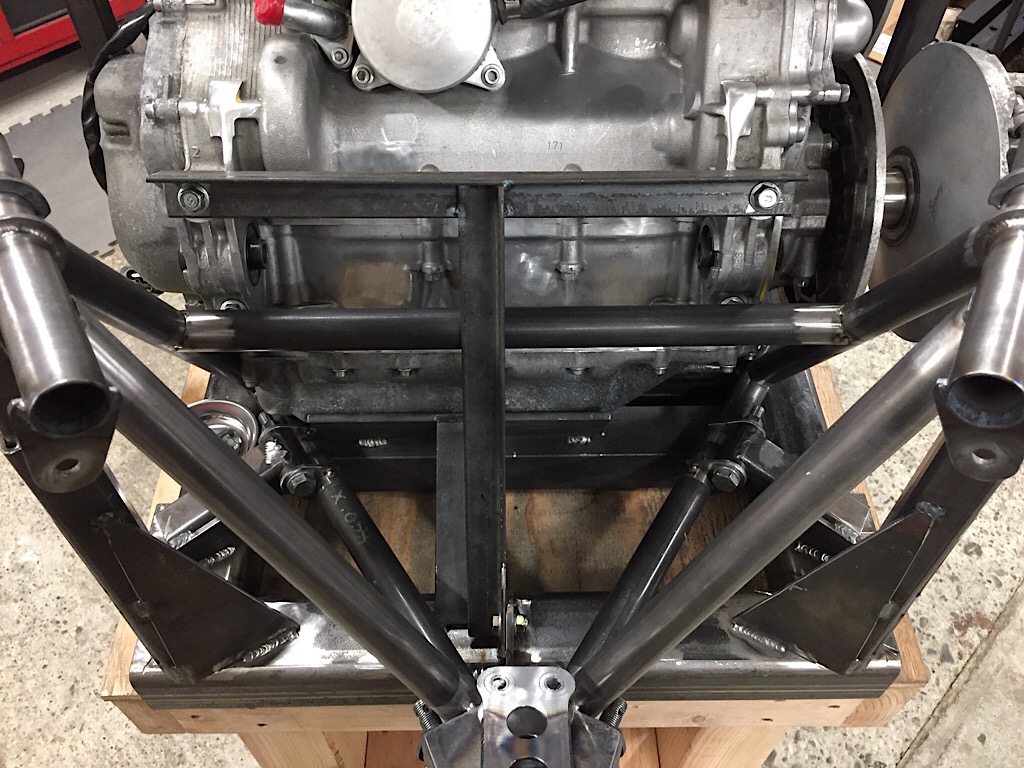

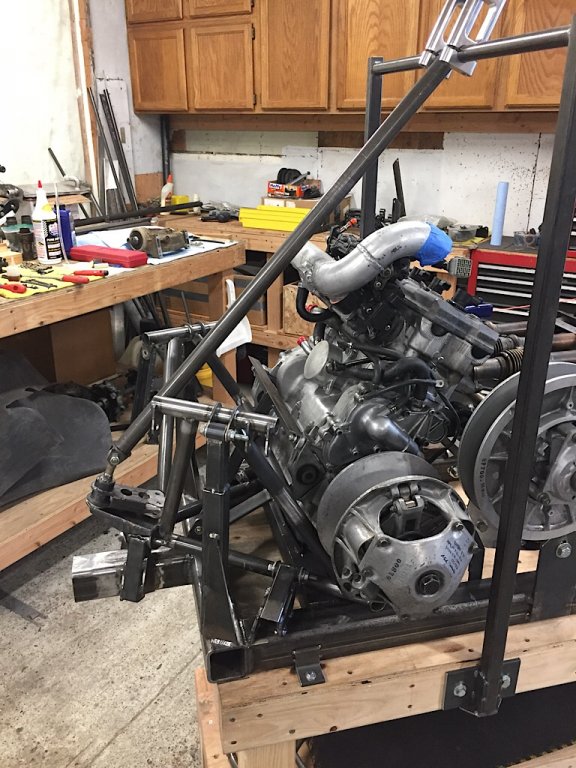

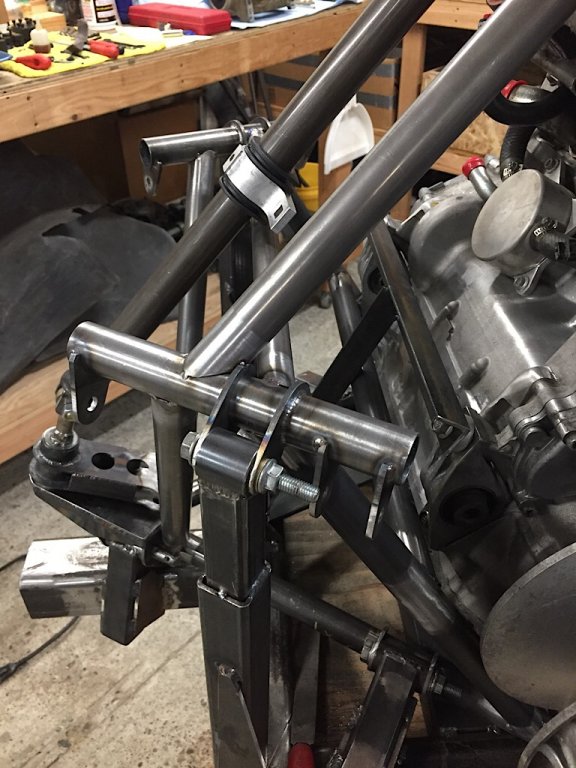

Got both .049 down tubes & the .049 motor mount tube all fit & tacked in place. Both down tubes are in the same position left to right, everything just fit.

Clearance

Clearance

Clearance

Clearance

Nikolai

TY 4 Stroke God

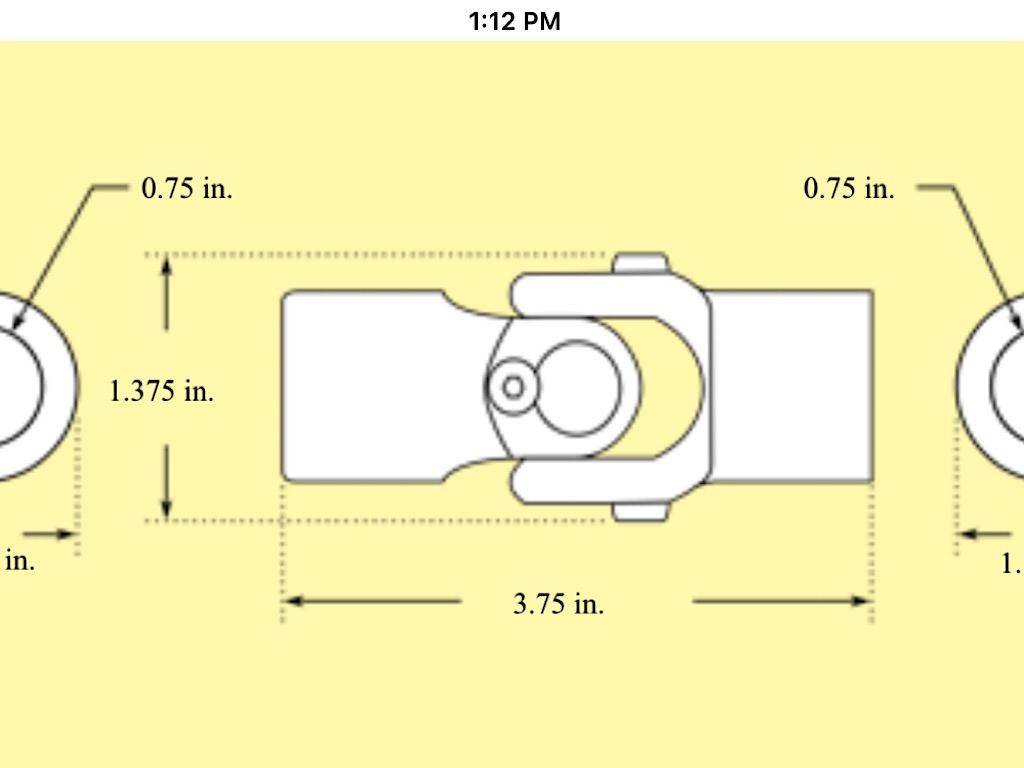

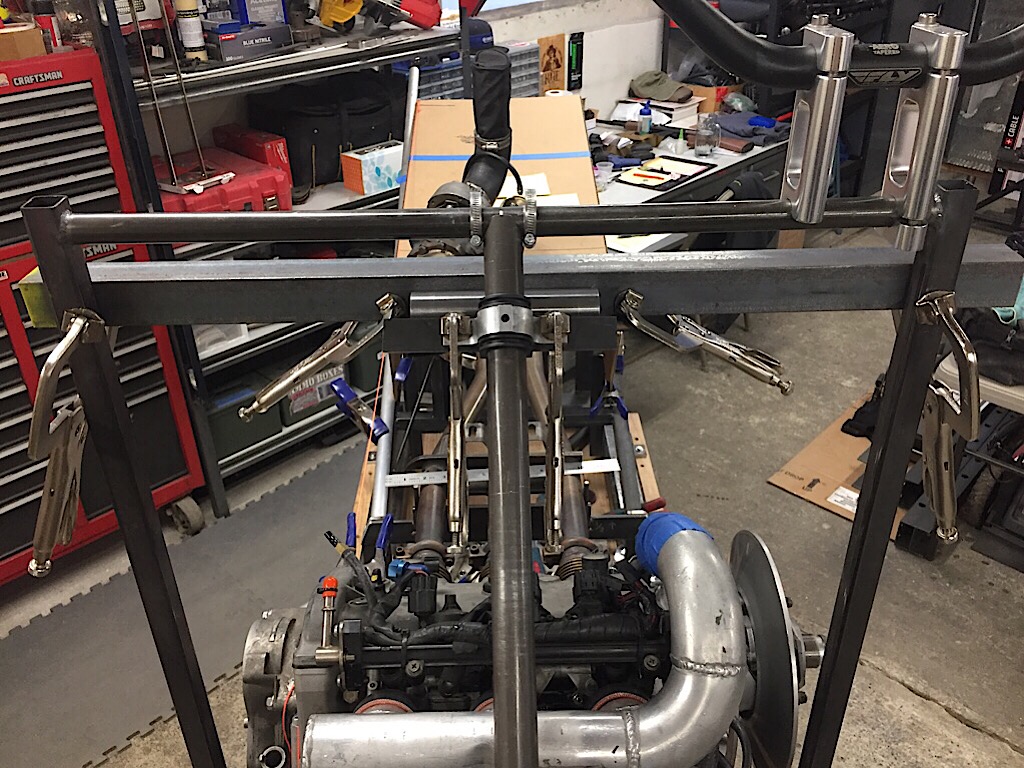

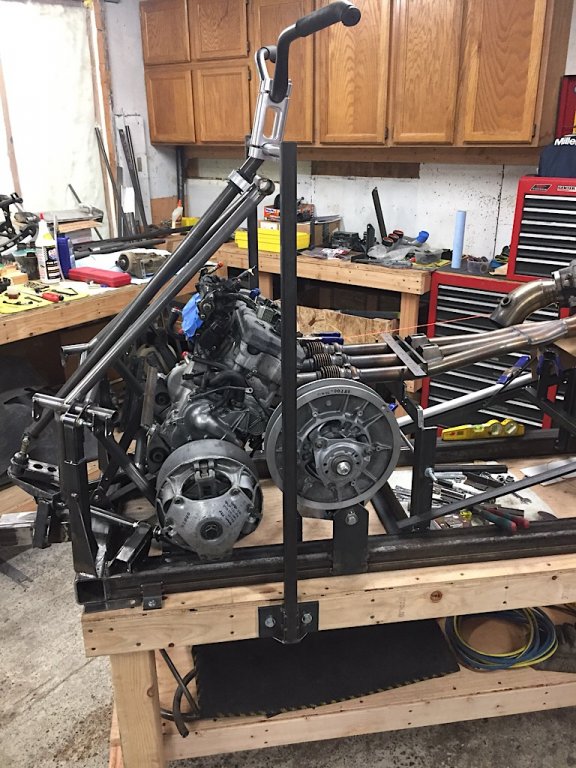

In an effort to keep going on the sled without spending money on parts, I used the dimensions of the steering u-joint I plan on using and mocked up a post so I could place & fit the tube that goes in between the shock mounts.

I’m making an assumption that the pivot point is directly center which would be half of 3.75”.

1.875” from where it will be welded to the steering arm to center of pivot.

Steering post is 1-1/8” so I made an end using 1” tube so I could slide my piece of 1-1/8” over the end.

Now that the post is located I can fit the tube between the shock mounts.

I’m making an assumption that the pivot point is directly center which would be half of 3.75”.

1.875” from where it will be welded to the steering arm to center of pivot.

Steering post is 1-1/8” so I made an end using 1” tube so I could slide my piece of 1-1/8” over the end.

Now that the post is located I can fit the tube between the shock mounts.

Nikolai

TY 4 Stroke God

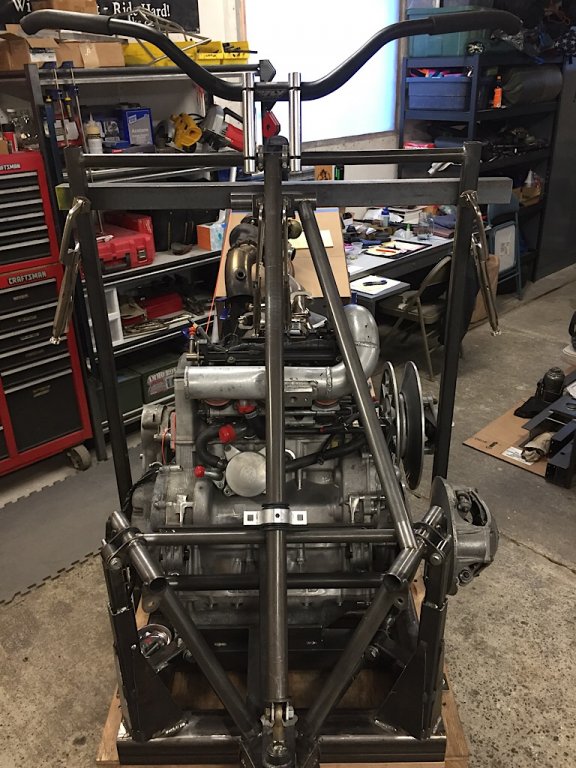

Got the shock mount cross tube in. I used 3/4 x .035 since the motor mount tube is helping to brace as will the spars to the steering hoop.

Nikolai

TY 4 Stroke God

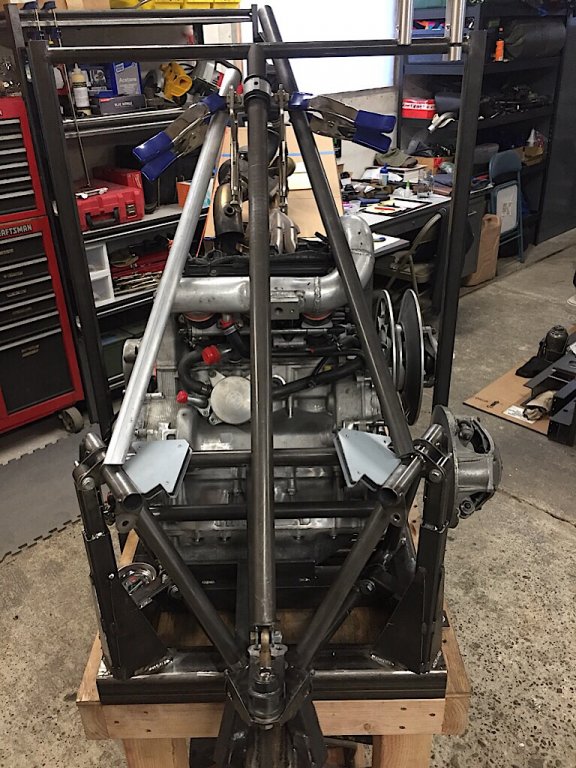

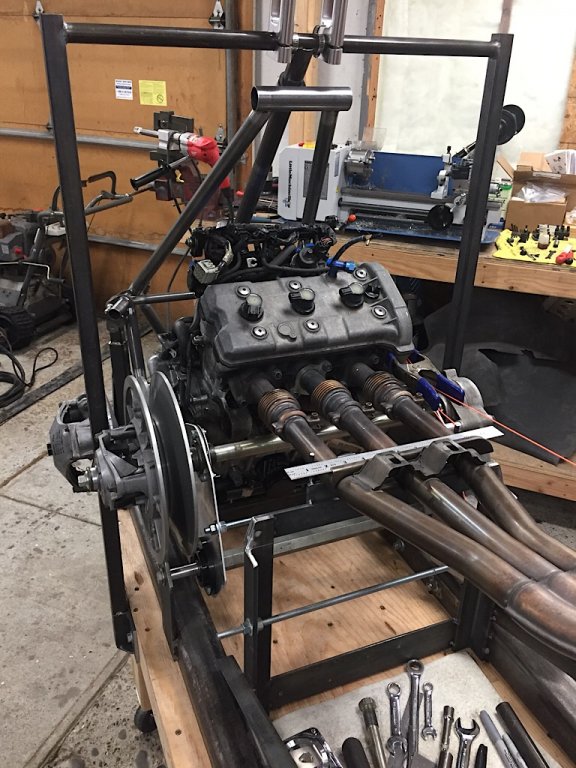

Mocking up the spars to get an idea of the charge tube clearance and IQR post mount bracket location.

I’m using a piece of 1-1/4 x .058 for the top tube since there’s going to be four 1” tubes welded to it. Getting the location of the 1-1/4 tube set.

One side in and tacked. The spars are 1 x .035 to keep the weight down.

Charge tube clearance.

I brought the spar into the shock mount as far as I could without hitting the charge tube. In hindsight, it would have been easier to do all the tubing first and then the a-arm and shock tabs. It would have made it easier to get all the tubes into the same node. Oh well, live and learn for the next one.

I’m using a piece of 1-1/4 x .058 for the top tube since there’s going to be four 1” tubes welded to it. Getting the location of the 1-1/4 tube set.

One side in and tacked. The spars are 1 x .035 to keep the weight down.

Charge tube clearance.

I brought the spar into the shock mount as far as I could without hitting the charge tube. In hindsight, it would have been easier to do all the tubing first and then the a-arm and shock tabs. It would have made it easier to get all the tubes into the same node. Oh well, live and learn for the next one.

Nikolai

TY 4 Stroke God

I made the mag side spar an 1/8” too short and didn’t have anymore .035 so I had to grind the tack welds and remove the pto side spar and shorten it an 1/8 so both sides would match. Use to have an old plumbing saying “We do it nice because we do it twice”, it’s applying to this sled a lot.

The next thing I’m going to work on is the lower 1” x .058 tube that will go from the front section all the way to the rear suspension mount.

The next thing I’m going to work on is the lower 1” x .058 tube that will go from the front section all the way to the rear suspension mount.

Nikolai

TY 4 Stroke God

I’ve been trying to come up with a tunnel design. Trying to stick to a few guidelines

- Must be strong

- Trying not to use a structural tunnel skin or any skin at all

- Tubing needs to support the turbo, header and fuel tank as well as the rear suspension mounts

- Complete tunnel weight under 20 lbs not including the coolers

Quite a few posts back I talked about doing two small stacked coolers in order to make the tunnel shorter, I’m going to try this. So far this is what I’ve come up with.

The lower tube will either be .049 or .058 (I will use .049 is it bends without deforming the tube). The tube will end directly behind the cooler as pictured.

I may make a short piece of aluminum tunnel to rivet to the tubing to support the cooler if it weighs less than the tubing required would. The aluminum piece would be small, basically the permanent marker lines

The downside to the short tunnel would be getting covered in snow by the track. My thought here is to cut a piece of 1/8 UHMW the width of the tunnel that extends back towards the track. It would attach with quick release pins to two small pivot points on the tube behind the cooler. Then from about the last 1/3 of the UHMW I’d run a small cable to the tubing supporting the header to keep the UHMW piece in place. It might tear up the UHMW in a roller but the stuff is pretty dang durable, cheap and I have a lot of it leftover from a previous project.

Anyway, that’s where I’m at. I don’t know what the tubing will look like yet. I need to do the lower tubes and then finish the steering hoop and chaincase supports next.

- Must be strong

- Trying not to use a structural tunnel skin or any skin at all

- Tubing needs to support the turbo, header and fuel tank as well as the rear suspension mounts

- Complete tunnel weight under 20 lbs not including the coolers

Quite a few posts back I talked about doing two small stacked coolers in order to make the tunnel shorter, I’m going to try this. So far this is what I’ve come up with.

The lower tube will either be .049 or .058 (I will use .049 is it bends without deforming the tube). The tube will end directly behind the cooler as pictured.

I may make a short piece of aluminum tunnel to rivet to the tubing to support the cooler if it weighs less than the tubing required would. The aluminum piece would be small, basically the permanent marker lines

The downside to the short tunnel would be getting covered in snow by the track. My thought here is to cut a piece of 1/8 UHMW the width of the tunnel that extends back towards the track. It would attach with quick release pins to two small pivot points on the tube behind the cooler. Then from about the last 1/3 of the UHMW I’d run a small cable to the tubing supporting the header to keep the UHMW piece in place. It might tear up the UHMW in a roller but the stuff is pretty dang durable, cheap and I have a lot of it leftover from a previous project.

Anyway, that’s where I’m at. I don’t know what the tubing will look like yet. I need to do the lower tubes and then finish the steering hoop and chaincase supports next.

So impressed by your creativity, ingenuity and skills ... the fact that you take all the pics and share them here is just icing on the cake.

Nikolai

TY 4 Stroke God

Thankyou.

Did some math today. The lower tubes would be 11 ft for both, even if I used .058 that’s only 6.49 lbs. I would use leftover 1 x 1/2 x .035 rectangle for the supports going from the rear susp mount to the steering hoop. These would be 5 ft for both and 1.701 lbs. The rear cross tube would be .049 and .67 lbs. The running boards I cut off my old build are 3.1 lbs for both. So that’s a total of 11.781 lbs.

That leaves me 8.219 lbs for the rear suspension mounts, gas tank & header support, turbo hanger, cooler support and rear flap and some thin tunnel skinning.

So I think 20 lbs for the complete tunnel is doable if I’m smart about it. Going to be close.

Did some math today. The lower tubes would be 11 ft for both, even if I used .058 that’s only 6.49 lbs. I would use leftover 1 x 1/2 x .035 rectangle for the supports going from the rear susp mount to the steering hoop. These would be 5 ft for both and 1.701 lbs. The rear cross tube would be .049 and .67 lbs. The running boards I cut off my old build are 3.1 lbs for both. So that’s a total of 11.781 lbs.

That leaves me 8.219 lbs for the rear suspension mounts, gas tank & header support, turbo hanger, cooler support and rear flap and some thin tunnel skinning.

So I think 20 lbs for the complete tunnel is doable if I’m smart about it. Going to be close.

Nikolai

TY 4 Stroke God

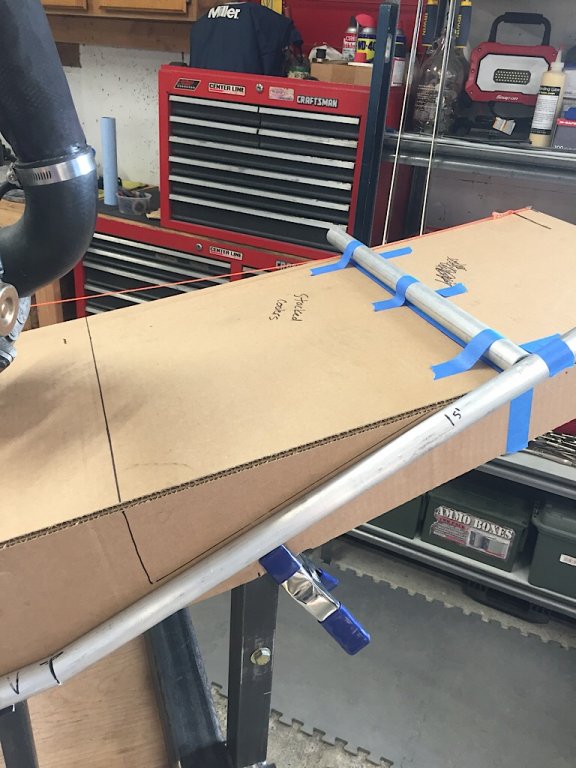

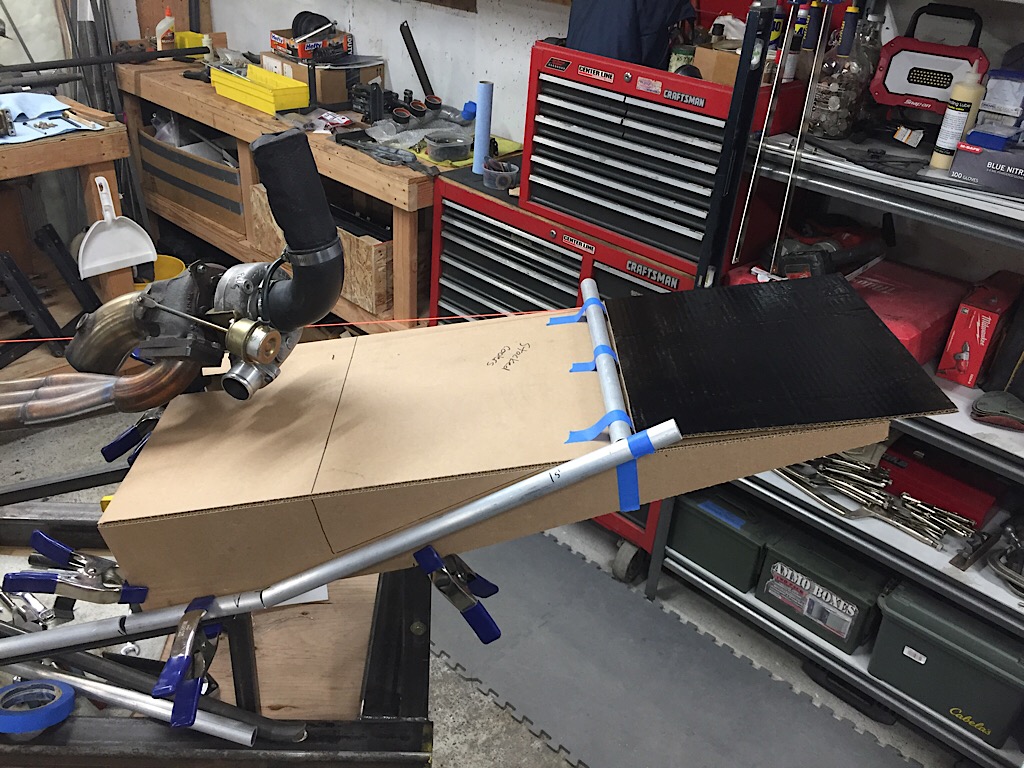

Just some more brainstorming. Cut out and painted a piece of cardboard to mimic the UHMW. It would be 15.5” wide x 14” long. This would still be short of the end of the track but only by a few inches based on the 153 tunnel I’m pulling measurements from.

Instead of making it pivot & secured with a cable, I think I would weld 7 or 8 really small .040 tabs to the 1” tube and secure it with 6-32 screws. Less complex, lighter and easily replaceable.

Instead of making it pivot & secured with a cable, I think I would weld 7 or 8 really small .040 tabs to the 1” tube and secure it with 6-32 screws. Less complex, lighter and easily replaceable.

Nikolai

TY 4 Stroke God

Cut and bent a piece of UHMW just to see what it would look like. Weight is 1.03 lbs. I think I’m going to go ahead and build the tunnel this way and if it doesn’t work out I can always weld on a tunnel extension later.

I also may just run tubing all the way back. Not sure how well UHMW would hold up to sidehilling?

I also may just run tubing all the way back. Not sure how well UHMW would hold up to sidehilling?

Last edited:

Nikolai

TY 4 Stroke God

I keep going back and forth on what to do with the tunnel. I don’t want to have any tubes on the side where my legs will be so I’ll either have to get creative with bracing or run a typical .050 or .063 tunnel. The outside of my tunnel will be 15-11/16 and I want to keep the narrow/nimble feeling which is why I don’t want any tubes in the way.

I figured for now I’d just start on the lower tubes and maybe the rest will fall into place. I read a tip online to tack weld a piece of flat stock to the tube before bending so you can put a level or digital angle finder on it. Seemed like a good idea.

Got the bender setup tonight with the 3.5 CLR die. Ran out of time but I will start bending and fitting the lower 1 x .058 tubes tomorrow.

I may doing something similar to the Anchorage Yamaha Nypex. His tunnel is a 174 and is only .063 with all 3/4 x .035 tube and it’s plenty strong.

I figured for now I’d just start on the lower tubes and maybe the rest will fall into place. I read a tip online to tack weld a piece of flat stock to the tube before bending so you can put a level or digital angle finder on it. Seemed like a good idea.

Got the bender setup tonight with the 3.5 CLR die. Ran out of time but I will start bending and fitting the lower 1 x .058 tubes tomorrow.

I may doing something similar to the Anchorage Yamaha Nypex. His tunnel is a 174 and is only .063 with all 3/4 x .035 tube and it’s plenty strong.

Similar threads

- Replies

- 623

- Views

- 225K

- Replies

- 29

- Views

- 7K

- Replies

- 466

- Views

- 122K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.