ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

I hear ya Joe.....I totally get what Mike is doing, and Im sorta like him where Id rather make up my own fix. And Mike does not want the oil blowing back into his turbo/tract anyway, so its a great idea. And Mike has been messing with turbos for awhile.I agree Dan! Give us a proper tank seal and valve. All this internet engineering is getting out of hand. If we all do this mod then Yamaha will come out with nothing to fix the real problem. I want to find out about this tank recall before I do anything.

But I agree Id like to not really start modding my few WEEK old NEW sled if Yamaha is going to end up fixing it? But will they? And how long? Will it actually fix the problem? And Will mine freeze and push oil before then? LOL

I just dont want to have to fix the seal. I realize most of these are 17 guys, and maybe it takes an entire season to push oil and I would be fine? But who knows at this point. GRRRR

Dan

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Reaction score

- 1,437

- Points

- 958

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

That is correct.

Also correct.

The air and vapor coming out of the tube is no different than I had with the Doo 1200 and I have never had it freeze up ever as there is plenty of heated air going thru it, but yes that is a concern I agree. One option is to put a slit in the tube up higher, Ski-Doo does this on the stock 1200's and if I remember correctly, I think the Apex have a slit cut into the tube as well in case it freezes on the end of the tube. Just a 1" slit cut into the tube would give it a relief valve so to speak.

What I have found in the real world is the air coming from the tube is heated and poses no icing concerns that I have seen on the 1200 Doos, and in reality the YamaCat should be even warmer in this department with the added exhaust and oil tank heat, hence the reason I used the reflective heat foil tape on it.

The volume of air coming out of it is no different that I've seen from the 1200 Doo, I'm confident that the Rotax vent "rollover" valve will work fine as well. The Doo uses the same oil scavenge pump design as the Yamaha does, but I'm not too concerned running straight thru without a valve for now. The Suzuki never had any type of valve from the factor at all either.

Thanks for all your info Mike. I remember seeing the slit in the 1200 tube and some guys thought it was a defect and taped it over with electrical tape. Say I don't want to do the whole mod like you did I was thinking about cutting a couple slits in the tube just before the roll over valve on my Winder. Won't this also work as a relief valve in case the valve freezes?

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Mike....

OK, what would be wrong with a smaller diameter tube? Im just thinking out loud here.

It should still allow for pressure/vapor escaping as its open at the end, same as yours.....

I just wondered as it seems a smaller diameter hose/tube would be easier to install in there, and look good too.

Would a small hose like fuel line(clear tube) melt though?

On our oil tank, we have a clear hose where we can view our oil level, and it does NOT melt. So why not just run something smaller like this, in exact same manner as you did?

Nothing wrong with yours, just thinking smaller hose, and I have lots of that size stuff around the shop and so It would be nice to rig this up without having to do a run to town.

Let me know your thoughts on diff diam hose

thnx

Dan

OK, what would be wrong with a smaller diameter tube? Im just thinking out loud here.

It should still allow for pressure/vapor escaping as its open at the end, same as yours.....

I just wondered as it seems a smaller diameter hose/tube would be easier to install in there, and look good too.

Would a small hose like fuel line(clear tube) melt though?

On our oil tank, we have a clear hose where we can view our oil level, and it does NOT melt. So why not just run something smaller like this, in exact same manner as you did?

Nothing wrong with yours, just thinking smaller hose, and I have lots of that size stuff around the shop and so It would be nice to rig this up without having to do a run to town.

Let me know your thoughts on diff diam hose

thnx

Dan

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Yes the apex had the slit and many guys were taping it, thought it was a flaw..lol.Thanks for all your info Mike. I remember seeing the slit in the 1200 tube and some guys thought it was a defect and taped it over with electrical tape. Say I don't want to do the whole mod like you did I was thinking about cutting a couple slits in the tube just before the roll over valve on my Winder. Won't this also work as a relief valve in case the valve freezes?

It was in airbox.

I said this long time ago, why cant we just drill a PIN HOLE(very small) into the plastic filler cap? small so no oil would spill out obviously, but release pressure. Not big enough to leak much at all in a roll.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Or maybe a simple tee in the hose above the tank, to a small 1/4" fuel line type hose, to allow release out, even could drop that down out floorboard like Mikes.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Only worry is leaking oil out where all that hot muffler and outlet is, would be my concern.Thanks for all your info Mike. I remember seeing the slit in the 1200 tube and some guys thought it was a defect and taped it over with electrical tape. Say I don't want to do the whole mod like you did I was thinking about cutting a couple slits in the tube just before the roll over valve on my Winder. Won't this also work as a relief valve in case the valve freezes?

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,849

- Reaction score

- 6,118

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Thanks for all your info Mike. I remember seeing the slit in the 1200 tube and some guys thought it was a defect and taped it over with electrical tape. Say I don't want to do the whole mod like you did I was thinking about cutting a couple slits in the tube just before the roll over valve on my Winder. Won't this also work as a relief valve in case the valve freezes?

Yes it would, however the pressure is all going to come out there as the factory blow off valve is spring loaded and takes pressure to open it up, nothing will go thru the valve and EVERYTHING would come out the slit cut before the valve. I WOULDN'T DO THAT.

The thing I don't like about a slit cut, is you have a chance of messing the sled up a bit from the oil weeping past and making a mess. Not too much of a concern on my setup, but a certain mess if you do it before the stock factory valve.

Keep in mind this mod I did is so easy to remove and go back to stock its silly. Cut the wrap ties take the Ace Hardware tube out and hook the stock tubing and rollover valve back up and add new zip ties to hold the reverse electrical back in place.

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Reaction score

- 1,437

- Points

- 958

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

Thanks for all the responses guys and suggestions. I have a headache now and I'm going to go take some pain killers.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,849

- Reaction score

- 6,118

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Mike....

OK, what would be wrong with a smaller diameter tube? Im just thinking out loud here.

It should still allow for pressure/vapor escaping as its open at the end, same as yours.....

I just wondered as it seems a smaller diameter hose/tube would be easier to install in there, and look good too.

Would a small hose like fuel line(clear tube) melt though?

On our oil tank, we have a clear hose where we can view our oil level, and it does NOT melt. So why not just run something smaller like this, in exact same manner as you did?

Nothing wrong with yours, just thinking smaller hose, and I have lots of that size stuff around the shop and so It would be nice to rig this up without having to do a run to town.

Let me know your thoughts on diff diam hose

thnx

Dan

I think the clear stuff may melt thru easier as it is directly above the exhaust, the braided stuff I used, holds it shape better when you make the loop up top I've found, less prone to kinking when you bend it like that.

Who cares what it looks like Dan, We don't ride with the panels off.

You could try a bit smaller hose, just not sure it won't kink and how you'd get it over the oil tank nipple. Try it if you want and see how it works. Just make sure it will flow good and hold the electrical off the exhaust. Remember larger Dia and thicker wall thickness is strong for that.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

OK got it....Im just trying to work with some materials I have already is all.I think the clear stuff may melt thru easier as it is directly above the exhaust, the braided stuff I used, holds it shape better when you make the loop up top I've found, less prone to kinking when you bend it like that.

Who cares what it looks like Dan, We don't ride with the panels off.

You could try a bit smaller hose, just not sure it won't kink and how you'd get it over the oil tank nipple. Try it if you want and see how it works. Just make sure it will flow good and hold the electrical off the exhaust. Remember larger Dia and thicker wall thickness is strong for that.

I may just tee it off, so I dont need to plug other end ect.....Ill leave all that in tact if I can tee off and run same loop and down out bottom.

I agree the TEE will mean cutting the hose above tank, and so there is no going back and would have to buy a new hose there. But that is not a biggie.

Could care less about looks....more about using plumbing stuff I have lying around here. If I was home in city Id just go grab stuff....lol

Dan

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Reaction score

- 1,437

- Points

- 958

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

I would think the smaller hose would be more likely to freeze also.I think the clear stuff may melt thru easier as it is directly above the exhaust, the braided stuff I used, holds it shape better when you make the loop up top I've found, less prone to kinking when you bend it like that.

Who cares what it looks like Dan, We don't ride with the panels off.

You could try a bit smaller hose, just not sure it won't kink and how you'd get it over the oil tank nipple. Try it if you want and see how it works. Just make sure it will flow good and hold the electrical off the exhaust. Remember larger Dia and thicker wall thickness is strong for that.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

any size hole will release pressure though Joe....that is my thought.I would think the smaller hose would be more likely to freeze also.

The stock rollover valve freezes cause its closed shut when sled is not running.

No reason for 1/4" hose to freeze.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

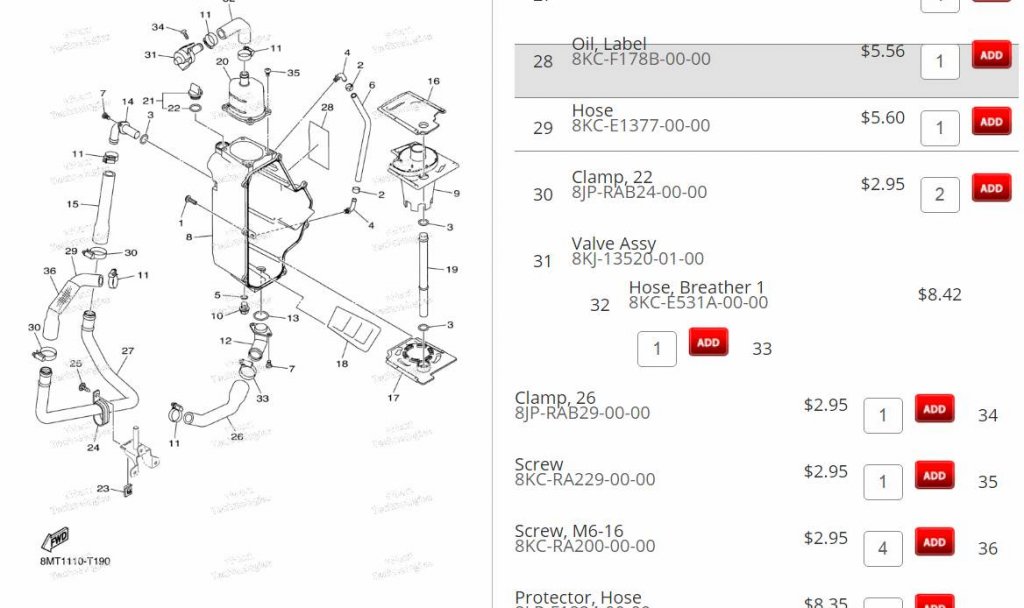

Interesting....when you go on Micro-fiche, the rollover valve shows not avail

8KJ-13520-01-00

8KJ-13520-01-00

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

That large 5/8" hose is only 8 bucks, so if I hack mine up its not a big deal really.

NYTurbo

TY 4 Stroke God

- Joined

- Sep 26, 2017

- Messages

- 1,567

- Reaction score

- 1,372

- Points

- 958

- Location

- Ottawa

- Country

- Canada

- Snowmobile

- Sidewinder

Get enough moisture anything can freeze. Went through this on a breather tube for my atv, no roll over valve , was vented into air box, had a slit in the tube but froze solid before the slit. Blew the side out of the oil reservoir and sounded like a shotgun going off so lots of pressure there. Think Mike' idea with the clear hose is a good idea at least you could check it for blockage.

Similar threads

- Replies

- 0

- Views

- 768

- Replies

- 210

- Views

- 52K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.