Nikolai

TY 4 Stroke God

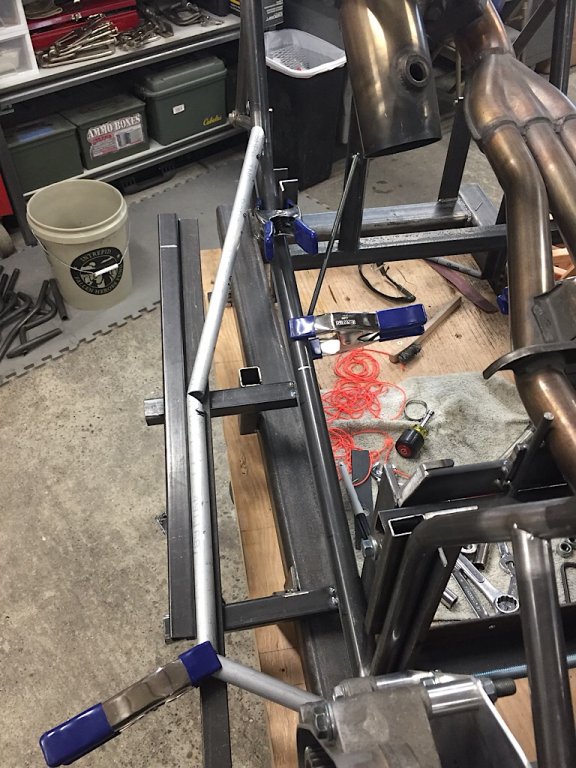

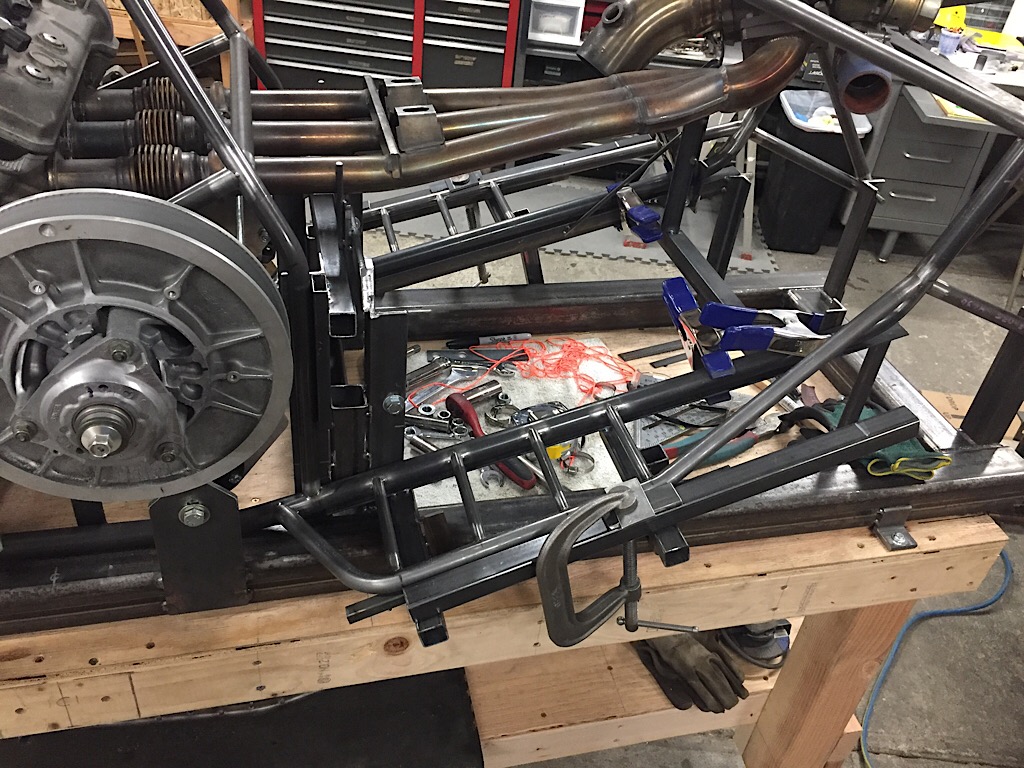

I decided to go with option 1 and make the boards small. Same mentality as the rest of the chassis, it’s easy enough to add tubing later if it needs more length or support, but might as well start with the lightest setup.

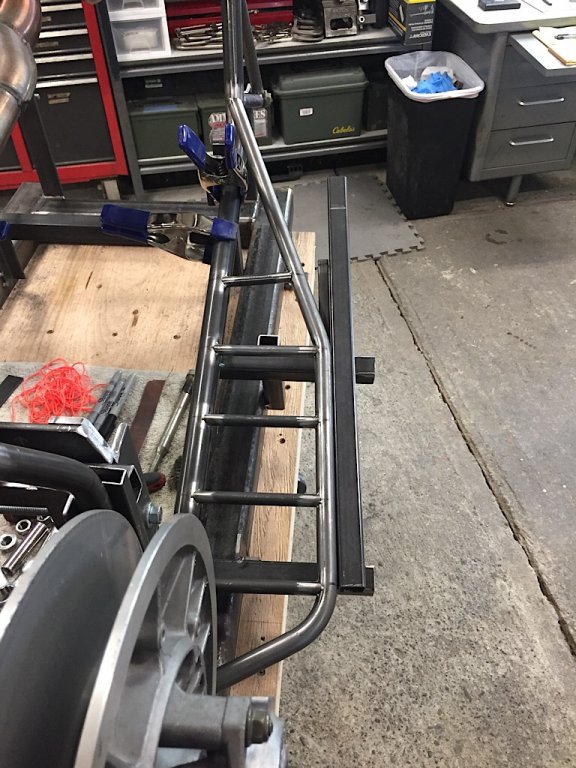

After speaking with a few people who ride a lot, sounds like 6.5” of width is plenty, so I brought the front of the tube into 6.5” total width(from tunnel skin to outside of 3/4 tube) and it tapers back. Fixed the jig so it’s ready to go now.

I’m using 3/4 x .035 and was having a really difficult time bending it without wrinkling. I finally figured out that the tube was slipping in the clamp and even just 1/16 - 1/8 of slippage was enough to wrinkle it. So I made a crude second clamp out of 7/8 .058 to help hold the tube and it worked awesome.

Bent to 70 degrees with almost no deformation and that’s a 2” CLR. I didn’t try going past that because it’s all I need for the front bend.

Took me a couple days to figure out the bending issue but now I can get the boards finished up.

After speaking with a few people who ride a lot, sounds like 6.5” of width is plenty, so I brought the front of the tube into 6.5” total width(from tunnel skin to outside of 3/4 tube) and it tapers back. Fixed the jig so it’s ready to go now.

I’m using 3/4 x .035 and was having a really difficult time bending it without wrinkling. I finally figured out that the tube was slipping in the clamp and even just 1/16 - 1/8 of slippage was enough to wrinkle it. So I made a crude second clamp out of 7/8 .058 to help hold the tube and it worked awesome.

Bent to 70 degrees with almost no deformation and that’s a 2” CLR. I didn’t try going past that because it’s all I need for the front bend.

Took me a couple days to figure out the bending issue but now I can get the boards finished up.

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,410

- Reaction score

- 1,547

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

I like! 2 days to figure out a bend solution is what holds me back from doing something like this LOL. I have no patience left anymore.

Nikolai

TY 4 Stroke God

We had our baby boy on the 27th at 8:00 PM so progress will slow for a bit as we adjust. He was a healthy 9 lbs 6 oz and is doing great.

I managed to get the outer tubes bent and fit before he got here, just need to be tacked and I’ll do the cross tubes.

I managed to get the outer tubes bent and fit before he got here, just need to be tacked and I’ll do the cross tubes.

Congratulations! Your first?We had our baby boy on the 27th at 8:00 PM so progress will slow for a bit as we adjust. He was a healthy 9 lbs 6 oz and is doing great.

I managed to get the outer tubes bent and fit before he got here, just need to be tacked and I’ll do the cross tubes.

Nikolai

TY 4 Stroke God

Thankyou. He is our second child, our daughter is 2.5 years old.

Brotherdan

Expert

- Joined

- Sep 8, 2017

- Messages

- 376

- Reaction score

- 153

- Points

- 458

- Location

- Belmont,maine

- Country

- USA

- Snowmobile

- 2011 apex xtx blue, starr suspension,gytr front shocks,camso 1.5 track cut down, snowtrackers work in process,2003 rx1er originally 121 converted to 136"monoshock 2 ck136 rear suspension with clicker vector ltx shock,muffin works tunnel extension, seat concepts(wrp) seat,apex hooked handlebars converted to all underhood wiring,8"lake effect billet aluminum riser,gytr frontshocks,yamaheater hand warmer kit,rocks ridelite,rocks power supply, rocks heated bag,, tunnel braces,blue skid plate,garmin gps, aggressive snowtrackers on apex single keel skis,rollerski ski wheel kit,108 warthog studs&blue studboy backers,pioneer wheel lowering kit, dupont slides, 4th wheel kit,yamaha saddle, tank& windshield bags, powermadd led handguards, bar mount mirror kit, apex radiator& electric fan added, apex rear cooler,autometer temp guage, apex new style large diameter drive shaft with extroverts machined for chaincase,thunder products clutching,1987 enticer 340ltr 2100miles,1984 enticer 340,1996 wolverine 350,big wheel kit,winch,racks,k&n,full skidplates

Congrats on your baby boy (you are very lucky to have 2 children&have a boy&a girl!!)I've been following your build &it's turning out great.I can appreciate all the time you have spent on this,some people have no idea how much time,tools,equipment,measuring,cutting,cleaning,grinding,research etc goes into a project like this especially when your on a budget&doing all the work yourself&trying to get the weight to a certain level,just the different types of welding clamps alone would baffle most folks.great job,I'm always looking forward to your posts as it progressesWe had our baby boy on the 27th at 8:00 PM so progress will slow for a bit as we adjust. He was a healthy 9 lbs 6 oz and is doing great.

I managed to get the outer tubes bent and fit before he got here, just need to be tacked and I’ll do the cross tubes.

Nikolai

TY 4 Stroke God

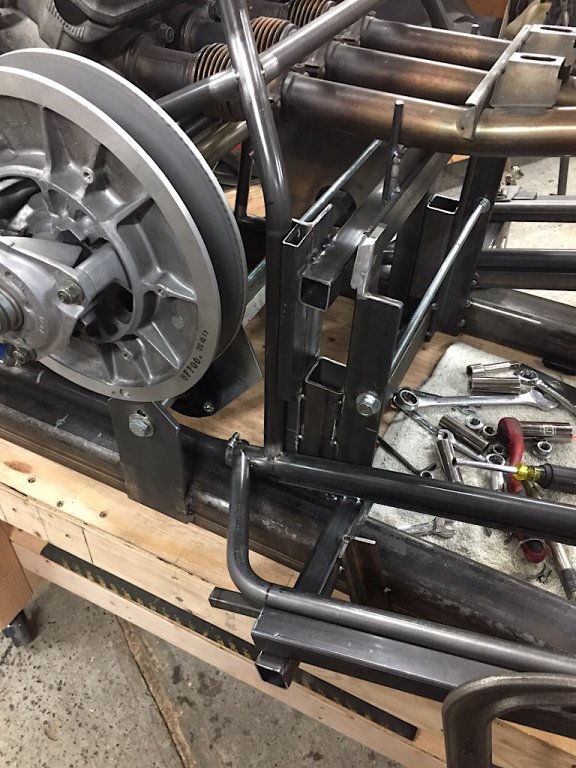

I got the outer tubes tacked. I need the runnings boards to be under 2.5 lbs complete(for both sides) and I’ll be under that. The outer tubes were 1.40 lbs for both, that leaves me with 1.10 lbs for the cross tubes and traction screws.

Congrats on the birth of your son! Can't wait to see the build you do for the little ones ... finally, a new snoscoot tubie LOL!

Nikolai

TY 4 Stroke God

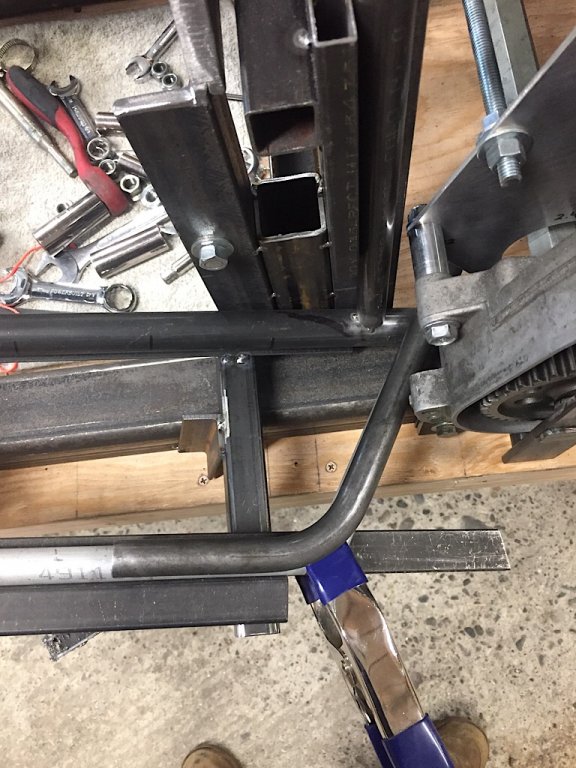

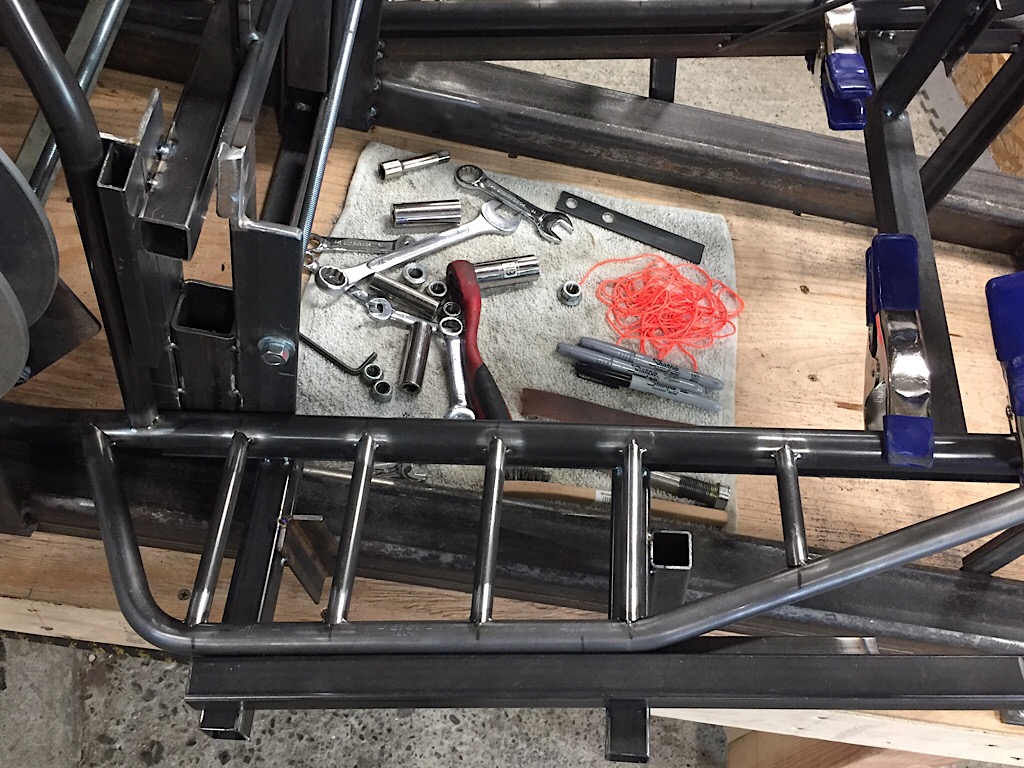

Not much progress, but I got some time to get the cross tubes on the Mag side in place. I’m using 1/2 x .035. I used 5/8 on the Nytro and they held up fine so I’m trying 1/2 this time. There will be a 5th tube out of 1/4 or 5/16 which I’ll do after all the 1/2 tubes are done. I’ve been weighing each tube so I can get a complete running board weight when I’m done.

Since my boards are narrower, the 1/2 tubes are all notched offset so they are nearly flush with the top of the 3/4 and 1 tubes.

Since my boards are narrower, the 1/2 tubes are all notched offset so they are nearly flush with the top of the 3/4 and 1 tubes.

Nikolai

TY 4 Stroke God

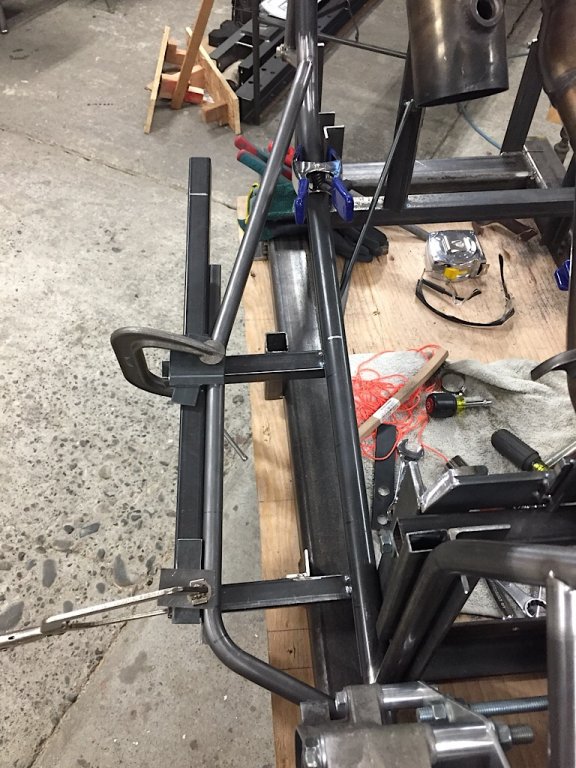

Got the clutch side cross tubes in.

I still need to do the 5th cross tubes and traction screws. I’m currently into both running boards for only 1.94 lbs so I’m doing good.

I still need to do the 5th cross tubes and traction screws. I’m currently into both running boards for only 1.94 lbs so I’m doing good.

sxr70001

Lifetime Member

- Joined

- Dec 4, 2010

- Messages

- 1,143

- Reaction score

- 761

- Points

- 1,288

- Location

- Michigan

- Country

- USA

- Snowmobile

- Sidewinder LTX SE

SR Viper RTX SE

Nice work! It's really starting to look like something now.

Nikolai

TY 4 Stroke God

I was going to use 5/16 for the 5th cross tube but I’m way under my weight so I decided to use 1/2 for added strength and keep them uniform. Running board weight is 2.03 lbs. 1.4 lbs for both 3/4 tubes and .63 lbs for all ten 1/2 tubes.

I had to bolt a small tab to the jig to hold the front outer corner of the board down. It wasn’t bent exactly right so I need to hold it down until it’s welded.

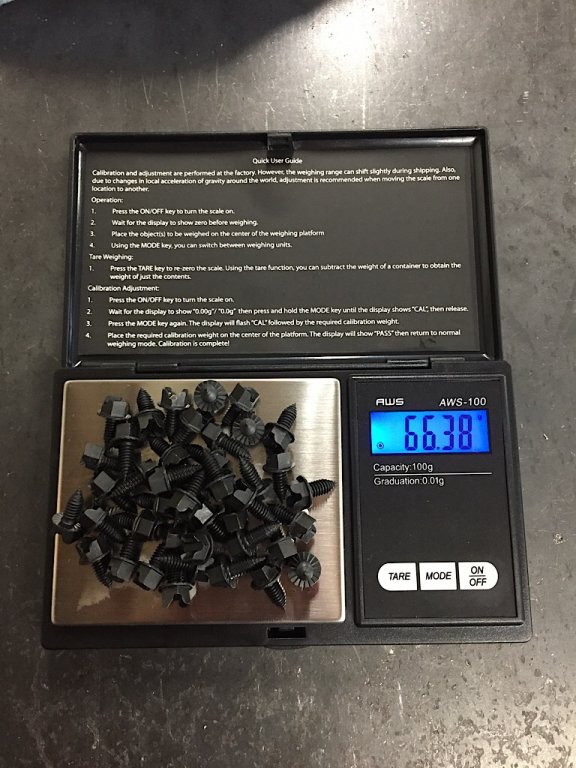

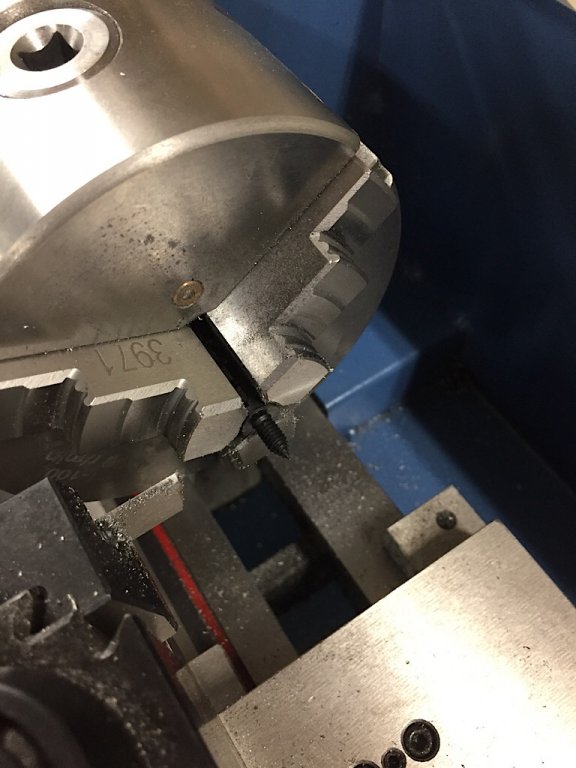

I’m using ice screws for traction, same as my Nytro. On the Nytro I drilled holes in the tubes and then welded the screws. That was a poor idea in hindsight because they need to be fully welded so the tubes don’t fill with water. This time I’m taking the tedious route of removing the shanks and only welding the heads on. Should have about a 30-40% weight savings and I’ll only need to tack weld them.

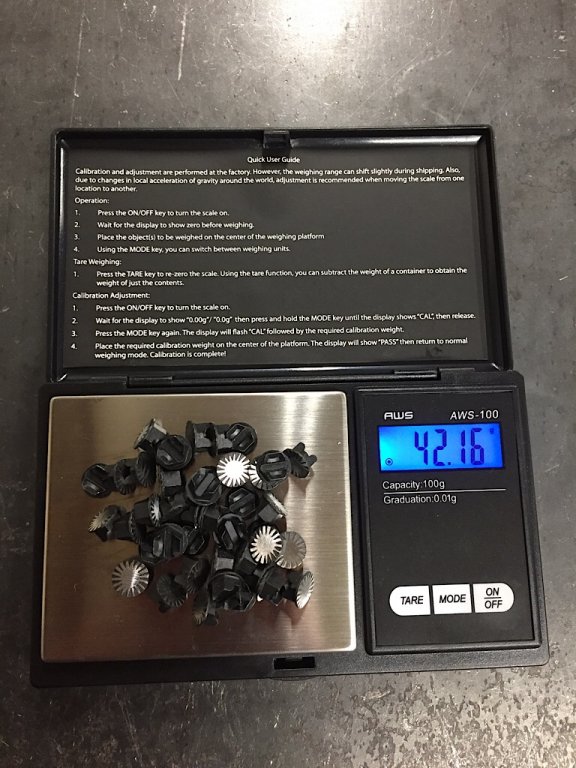

Each side will have 21 screws, 66.38 grams is for all 42. I’ll weigh them again once the shanks are off.

I had to bolt a small tab to the jig to hold the front outer corner of the board down. It wasn’t bent exactly right so I need to hold it down until it’s welded.

I’m using ice screws for traction, same as my Nytro. On the Nytro I drilled holes in the tubes and then welded the screws. That was a poor idea in hindsight because they need to be fully welded so the tubes don’t fill with water. This time I’m taking the tedious route of removing the shanks and only welding the heads on. Should have about a 30-40% weight savings and I’ll only need to tack weld them.

Each side will have 21 screws, 66.38 grams is for all 42. I’ll weigh them again once the shanks are off.

Last edited:

Nikolai

TY 4 Stroke God

Got the shanks cut off and then hit each one quick with a 3M disc. Took about an hour to do all 42.

36.5% lighter. Basically 1 gram per screw head, not too bad.

That puts the total running board weight at 2.123 lbs which is well under the 2.5 lb goal.

Next step for me is pretty much to weld everything I have done to this point.

36.5% lighter. Basically 1 gram per screw head, not too bad.

That puts the total running board weight at 2.123 lbs which is well under the 2.5 lb goal.

Next step for me is pretty much to weld everything I have done to this point.

Nikolai

TY 4 Stroke God

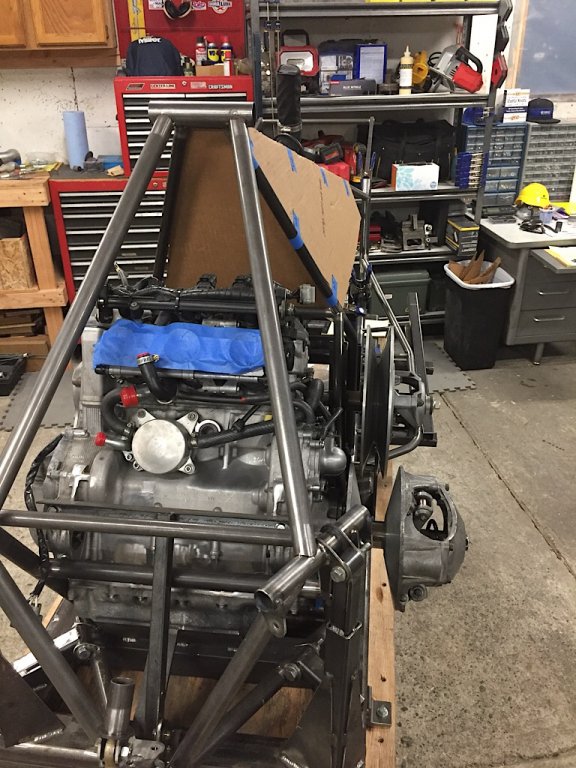

Made a sleeve from 1.125 tube to use as a guide and trimmed the 1” tubes to length. I left them a little over an inch long which should be more than enough to crimp the coolant hose to.

I’m not building the fuel tank for a long time but I wanted to get a rough idea of the size and feel now that I have running boards in place to stand on. Earlier in this thread I talked about the fuel tank being structural. I will likely bolt the fuel tank to the framing in 7 places (blue tape) on each side.

I’m not building the fuel tank for a long time but I wanted to get a rough idea of the size and feel now that I have running boards in place to stand on. Earlier in this thread I talked about the fuel tank being structural. I will likely bolt the fuel tank to the framing in 7 places (blue tape) on each side.

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,410

- Reaction score

- 1,547

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

Good solution on welding the traction screws vs drilling and letting the water in! I have never thought of that. The 'boards' look nice.

Similar threads

- Replies

- 623

- Views

- 216K

- Replies

- 29

- Views

- 6K

- Replies

- 466

- Views

- 120K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.