snowfever27

VIP Member

- Joined

- Jan 7, 2015

- Messages

- 235

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2015 Arctic Cat XF7000

2009 Yamaha Nytro XTX (sold)

2007 Yamaha Phazer FX (sold)

2005 Ski-Doo MZX 800 Adrenaline (sold)

2003 Arctic Cat F7 EFI (sold)

2007 Yamaha Attack

2009 Polaris 600 Dragon SP

- LOCATION

- Vermont

I figured you had a plan for it, either a custom tunnel or fix it. This sled won’t have any stock parts left when you’re done with it!

Nikolai

TY 4 Stroke God

Took me a while to get the main part of the jig done. Lots of clamping to get it perfectly straight. I don’t have a flat table at home so I welded it up at my works weld shop.

I didn’t have a chance to pick up the ‘16 tunnel but as soon as I do I’ll get the rear suspension front arm mounts in next.

I didn’t have a chance to pick up the ‘16 tunnel but as soon as I do I’ll get the rear suspension front arm mounts in next.

Just a fyi. the new lower drive shaft position is supposed be much better than the 2012 and 2016 viper there are a couple of places that sell a drop and roll kit. I think TKI is one of them.

Nikolai

TY 4 Stroke God

I’ve read that as well. I spoke with a buddy(dealer) who has ridden both side by side and he didn’t think there was a noticeable difference. Maybe it depends more on the type of snow? Our snow is fairly wet.

I am going to lower it, but due to the short 7” c to c of the Apex case it won’t be as much as the new models which were dropped 1.125”. I think I’ll be able to do 0.5”-0.75”. I figure either way it’s got to a be significantly better then the horrible approach angle the Nytro has.

This is a Powehouse Customs chassis. They use the Apex case and have a low approach angle, I’m shooting for something similar.

I am going to lower it, but due to the short 7” c to c of the Apex case it won’t be as much as the new models which were dropped 1.125”. I think I’ll be able to do 0.5”-0.75”. I figure either way it’s got to a be significantly better then the horrible approach angle the Nytro has.

This is a Powehouse Customs chassis. They use the Apex case and have a low approach angle, I’m shooting for something similar.

Nikolai

TY 4 Stroke God

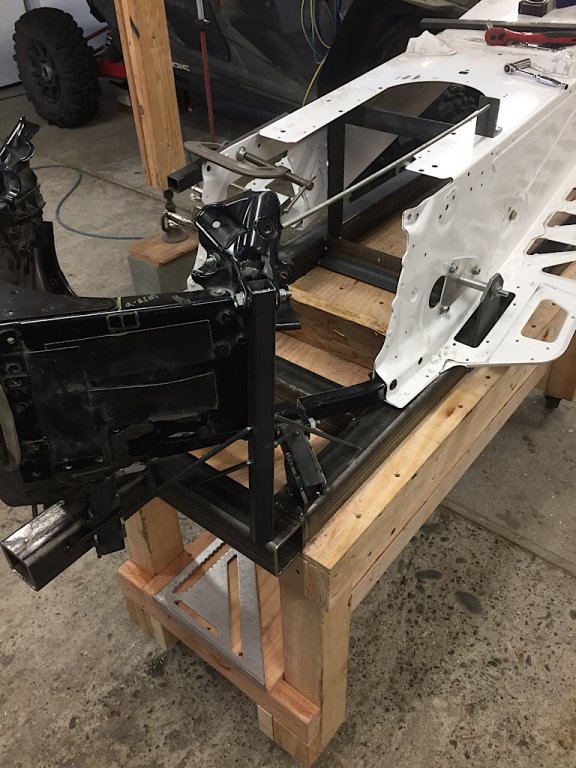

Picked up the 16 tunnel and started building a roll around table to put the jig on.

Nikolai

TY 4 Stroke God

Finished the table and got the rear suspension holes drilled. Spoke with my buddy quite a bit and he said they use the middle rear hole and lower front hole so that’s what I’m setting up the jig for. I measured a 2017 at the dealer and as they sit on the floor, the front bolt is 1” lower than the rear bolt. I did the same to the jig so that the sled is built in the position it will be at on the ground.

Got the uprights for the front holes welded in. My 2-1/2” square tube was a little off in width(probably from welding the jig) so I had to weld in an additional 15-5/8” piece of angle to spread it(needed to spread it 3/32) After I measure and drill the front holes I’ll bolt the tunnel back in and locate the driveshaft.

Got the uprights for the front holes welded in. My 2-1/2” square tube was a little off in width(probably from welding the jig) so I had to weld in an additional 15-5/8” piece of angle to spread it(needed to spread it 3/32) After I measure and drill the front holes I’ll bolt the tunnel back in and locate the driveshaft.

Nikolai

TY 4 Stroke God

Front arm holes located and drilled. Doing the driveshaft next and then running board angle.

The tunnel has some damage so I’ve been measureing off the jig to locate the holes to make sure it’s square.

The tunnel has some damage so I’ve been measureing off the jig to locate the holes to make sure it’s square.

Nikolai

TY 4 Stroke God

Found the driveshaft center and have a plan for the drivetrain, but I took a break to work on the front end which is going to be slow.

Nikolai

TY 4 Stroke God

It took a long time to get the front section straight but the rear a-arm mounts are now done and I got the tab for the driveshaft made. Going to work on the front a-arm mounts next.

Nikolai

TY 4 Stroke God

Finished the front a-arms. Next will be shock mounts.

I’m trying to build the jig in a way that’s the least cluttered and leaves the most room for welding tube.

I’m trying to build the jig in a way that’s the least cluttered and leaves the most room for welding tube.

kinger

VIP Member

Awesome love this!

Nikolai

TY 4 Stroke God

Part 1.

I’ve been working on the shock mounts for the last few days. I turned some spacers to fit inside 1” square tube which fits perfect inside the shock mount tabs. The PTO side shock mount is damaged on the frame assembly that I was given, so I tacked the MAG side first then spent 2 afternoons duplicating the measurements on the PTO side. I had to use some threaded rod attached to the tunnel to pull the shock mount back.

This is what I was left with after I removed the frame. Keep in mind the steel rod was just to hold the square tube in position, they will be heavily braced before I’m finished.

Once I was done, I put some 5/16 chromo tube through the shock mount holes and realized the PTO side wasn’t parallel to the lower a-arm. I had to cut most of the steel rods and twist the 1” square.

Although very close, the jig has to be perfect(eyeballing doesn’t cut it), so after all that work I came up with a plan B to make sure the shock mounts get welded in exactly the right location. I should be done with them in 2 days. But here is the start of part 2.

I’ve been working on the shock mounts for the last few days. I turned some spacers to fit inside 1” square tube which fits perfect inside the shock mount tabs. The PTO side shock mount is damaged on the frame assembly that I was given, so I tacked the MAG side first then spent 2 afternoons duplicating the measurements on the PTO side. I had to use some threaded rod attached to the tunnel to pull the shock mount back.

This is what I was left with after I removed the frame. Keep in mind the steel rod was just to hold the square tube in position, they will be heavily braced before I’m finished.

Once I was done, I put some 5/16 chromo tube through the shock mount holes and realized the PTO side wasn’t parallel to the lower a-arm. I had to cut most of the steel rods and twist the 1” square.

Although very close, the jig has to be perfect(eyeballing doesn’t cut it), so after all that work I came up with a plan B to make sure the shock mounts get welded in exactly the right location. I should be done with them in 2 days. But here is the start of part 2.

Nikolai

TY 4 Stroke God

This is going to be clear as mud. If anyone reading this owns a Viper, could you tell me what the approximate thickness of the shoulder of the bushing is that goes into the frame (that the steering arm goes into)? I need to know how far above the frame to space the steering arm when I jig it.

Nikolai

TY 4 Stroke God

For the shock mounts I took some 3/8 threaded rod and ran it through the a-arm mounts. I made some 12mm x 3/8 and 10mm x 3/8 reducers so the threaded rod would be centered in the mounts. Then based of the good(MAG) side, drilled my holes to locate the shock mounts. After getting everything adjusted properly and tight, the shocks mounts are in the correct position and parallel. I still need to do the bracing but the tedious measuring is over. I pulled multiple different measurements off the jig, centerline of chassis, rear suspension bolts, ect and the shock mounts are within 1/32 side to side.

My GUESS is .062in based off of what I did in this thread. Perhaps you could compare the pics to other accessible points on sled to measure. Maybe even a app. I reused the old bushings.This is going to be clear as mud. If anyone reading this owns a Viper, could you tell me what the approximate thickness of the shoulder of the bushing is that goes into the frame (that the steering arm goes into)? I need to know how far above the frame to space the steering arm when I jig it.

View attachment 143106

https://ty4stroke.com/threads/crash-damage-and-repair-info-and-pics.145856/

Similar threads

- Replies

- 4

- Views

- 4K

- Replies

- 32

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.