ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

I believe he mentioned he ordered from Hurricane if I recall...along with race rotor.Is that shaft OEM ?

lilrez

Expert

Ah yes good call. Theres the reason why not to bond the rotor to the bearing and allow it to float on the spline.The rotor is on splines and IMO is not a big deal and is meant to have some play. After I put mine back together with the green, My brake lever had a fair vibration in it initially, which took a ride or two to even out. Likely some green in there i felt.

Dan

and yes, correct. Ordered from Hurricane which has in stock and was excellent to deal with.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,382

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Rotor doesn't need to move, and I would prefer it tight. Too bad there wasn't a giant jam nut on the end of the shaft.

I believe he mentioned he ordered from Hurricane if I recall...along with race rotor.

Nice looking parts

I have this puller because heat was not enough one time and i have bend the caliper:-/ whit this type of puller its a piece of cake to pull out! STRAIGHT....

View attachment 148134 View attachment 148135 View attachment 148136

Approximately 2/3mm. It doesn't need to be perfect to work well. As you guys can see i am not an engineer

View attachment 148146

What size ready rod did you use to fit caliper threads?

lilrez

Expert

If it doesn't need to move and wont pulse the brake lever ....one could suggest to bond rotor and inner race...Rotor doesn't need to move, and I would prefer it tight. Too bad there wasn't a giant jam nut on the end of the shaft.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

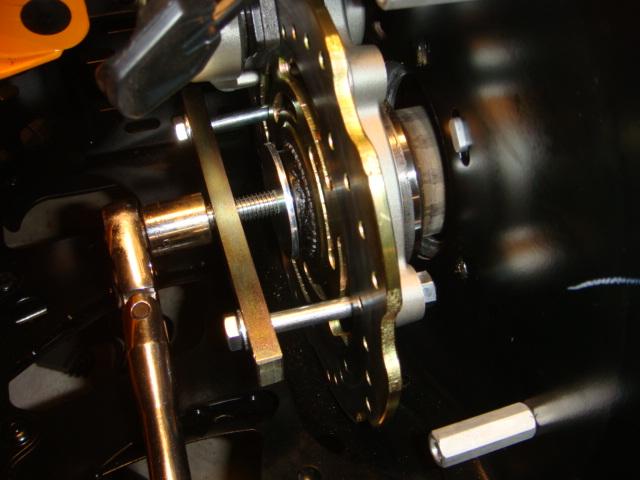

Here is a puller I used for my Doo awhile back....This could very well work for the Winder.

Basically a bar with two bolts to match caliper bracket threads, must have rotor with holes/slots ect. And also a large OD washer for center bolt to push on against end of hollow shaft. would need to apply heat into hollow shaft prior.

Dan

Basically a bar with two bolts to match caliper bracket threads, must have rotor with holes/slots ect. And also a large OD washer for center bolt to push on against end of hollow shaft. would need to apply heat into hollow shaft prior.

Dan

lilrez

Expert

Exactly what i was thinking Dan!...lol was looking for that pic you had on the 1200 working on the wifes sled last month..

Im thinking i can make use of the slots on my new rotor.

Was also wondering if the hole in the tunnel could be opened up one day if they decided to make the shaft a press fit like the doo

Im thinking i can make use of the slots on my new rotor.

Was also wondering if the hole in the tunnel could be opened up one day if they decided to make the shaft a press fit like the doo

lilrez

Expert

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,382

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

I th

I think it would let go after a few miles.If it doesn't need to move and wont pulse the brake lever ....one could suggest to bond rotor and inner race...

lilrez

Expert

Ok. Just found some loctite 620 bearing mount for a good price.

IH8CROWS

Expert

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,814

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

The good 638 loctite can be had from Amazon.

number1kyster

TY 4 Stroke God

View attachment 148305 How about this?

12.99 at Napa.

That is what I bought. I haven't used it yet through.

Byam

TY 4 Stroke Guru

I don't remember! But chek post #20 ;-)What size ready rod did you use to fit caliper threads?

Similar threads

- Replies

- 5

- Views

- 679

- Replies

- 13

- Views

- 2K

- Replies

- 36

- Views

- 6K

- Replies

- 327

- Views

- 58K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.