lilrez

Expert

Ive been very happy overall with this 998 with exception to a failed turbo at only 5000miles which was covered under warrentee even after it expired. After this many years there is no excuse for this bearing to still be an issue. Leaving it up to the consumer to tear apart and catch before warrentee runs out is a croc of #*$&@ to cat and yamaha and all dealers that know about it IMO.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,382

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Just not sure there would be the demand, that's all.I get that. Just saying most on here will not do it. I just would think of all the aftermarket stuff for this sled? Someone could do a shaft and make it BETTER.

IH8CROWS

Expert

I get that now but at the time that was all that was suggested and then other ideas started showing up after I had it back togetherPeening does nothing to hold the bearing, set screw into the bearing appears to hold it.

Loctite /set screw for example

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,265

- Age

- 50

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

I gotcha.Just not sure there would be the demand, that's all.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

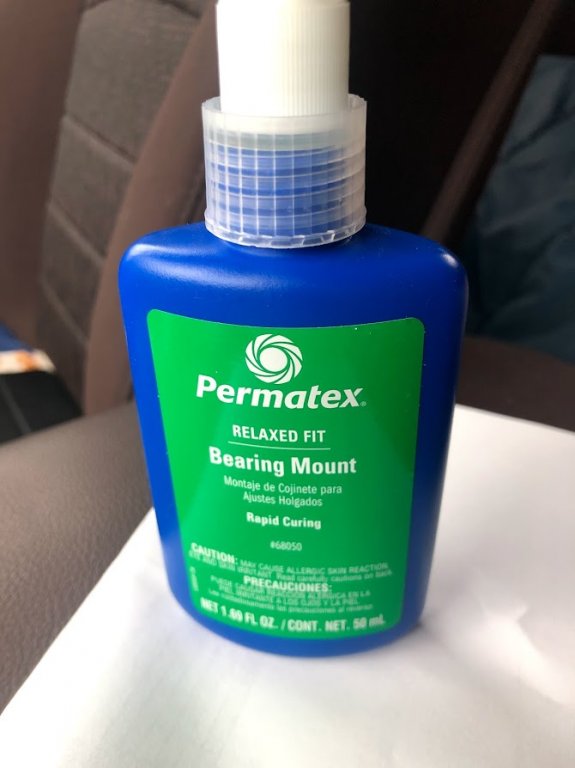

After lots of talk last winter with several diesel mechanics, they all said the bearing mount(green loctite) for loose fitment works for them. One tech told me they use it often for VERY loose fitment bearing(much looser then ours) and they still setup and lock the bearing tight. After these conversations I felt alot better about the bearing mount.

I like the idea of adding 3 small drill (semi)holes. I would use a small drill bit around 1/8" to drill into the shaft in 3 locations spread equally around the shaft under where bearing seats. (10,2,6 oclock) I would only drill into the shaft a slight depth(very shallow), NOT THROUGH the shaft. This will lend more 'bite' to the loctite, and since these holes are not drilled through, it allows it to set up since its anaerobic.

Dan

I like the idea of adding 3 small drill (semi)holes. I would use a small drill bit around 1/8" to drill into the shaft in 3 locations spread equally around the shaft under where bearing seats. (10,2,6 oclock) I would only drill into the shaft a slight depth(very shallow), NOT THROUGH the shaft. This will lend more 'bite' to the loctite, and since these holes are not drilled through, it allows it to set up since its anaerobic.

Dan

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Age

- 69

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

What do they recommend for removal? Maybe a little heat?After lots of talk last winter with several diesel mechanics, they all said the bearing mount(green loctite) for loose fitment works for them. One tech told me they use it often for VERY loose fitment bearing(much looser then ours) and they still setup and lock the bearing tight. After these conversations I felt alot better about the bearing mount.

I like the idea of adding 3 small drill (semi)holes. I would use a small drill bit around 1/8" to drill into the shaft in 3 locations spread equally around the shaft under where bearing seats. (10,2,6 oclock) I would only drill into the shaft a slight depth(very shallow), NOT THROUGH the shaft. This will lend more 'bite' to the loctite, and since these holes are not drilled through, it allows it to set up since its anaerobic.

Dan

View attachment 148239

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

I never had to remove mine after the loctite.What do they recommend for removal? Maybe a little heat?

But a few guys have mentioned, some heat inside the hollow end of axle which is easy to get at, then applying pressure to a puller would work well. Most guys have had to come up with a puller design. In the DOO world BRP uses a press fit and has a puller, or Chris at CT sells the pullers which I have two of(for doos) and I would think those could be made to work. Over here were are hoping Travis can make up a puller for this method.

The biggest issue guys need to consider when using loctite is.....you are best to do this BEFORE the bearing starts to slip. Reason is, once there is a space created by wear, it makes it hard to put thing back together with loctite, and have them centered so its balanced well.

The tugging of the weight of the track pulling on the axle, will end up having the loctite setup to one side(not centered) and then will have a vibration when run. Mine did not have much wear when I added the loctite, so it ended up fine without any vibrations when running sled.

So this is something that IMO needs to be done early on. It would be great if Cat/Yam just added the green loctite when NEW uppon assembly at the plant, then added a PULLER tool to their catalog and added heating instructions to the tech manual. This would allow them to "fix" this issue without really changing anything, since it seems they dont want to actually re-engineer this issue.

Dan

snow_rider

Extreme

- Joined

- Apr 2, 2009

- Messages

- 63

- Location

- Tawas City MI

- Country

- USA

- Snowmobile

- 2018 Sidewinder LTX-LE 50th

Amen!

As for removal, I had used the green cylindrical bonder on mine along with dimpling the shaft, early on (zero miles) as Dan mentioned. Then when I went to replace my stock (peer) bearing with a SKF (at approx 1000 miles), I needed heat and I used a two jaw puller that I got from my auto parts store. Once I had the correct puller, it really wasn’t that bad and it came off ok. Then when I installed the new bearing, I removed the dimples and just used the bearing retainer. I should also add that, after I had dimpled and bonded my stock bearing early on, there was no evidence of it ‘spinning’ on the shaft, so this fix does seem to work.

Steve

As for removal, I had used the green cylindrical bonder on mine along with dimpling the shaft, early on (zero miles) as Dan mentioned. Then when I went to replace my stock (peer) bearing with a SKF (at approx 1000 miles), I needed heat and I used a two jaw puller that I got from my auto parts store. Once I had the correct puller, it really wasn’t that bad and it came off ok. Then when I installed the new bearing, I removed the dimples and just used the bearing retainer. I should also add that, after I had dimpled and bonded my stock bearing early on, there was no evidence of it ‘spinning’ on the shaft, so this fix does seem to work.

Steve

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Amen!

As for removal, I had used the green cylindrical bonder on mine along with dimpling the shaft, early on (zero miles) as Dan mentioned. Then when I went to replace my stock (peer) bearing with a SKF (at approx 1000 miles), I needed heat and I used a two jaw puller that I got from my auto parts store. Once I had the correct puller, it really wasn’t that bad and it came off ok. Then when I installed the new bearing, I removed the dimples and just used the bearing retainer. I should also add that, after I had dimpled and bonded my stock bearing early on, there was no evidence of it ‘spinning’ on the shaft, so this fix does seem to work.

Steve

I believe the dimples can 'HELP' but this would be moreso on a nice tight fitment, like a NEW bearing/shaft ect. Although some have mentioned that even NEW parts had a loose fitment or high tolerance between race and axle.

The dimples or small shallow holes that I mentioned IMO will help grip the loctite more. But I think the bearing mount seems to be a must if you truly want this issue solved.

number1kyster

TY 4 Stroke God

I will be checking mine soon. The sled has 1,500 miles on it. Hopefully it is still tight.

lilrez

Expert

Looks good. Need to pick up some green goo, trace out dimensions for a future puller, and should be all set..

Hoping to find a smaller 6ml bottle of instead of a 50ml 60dollar bottle of the stuff.

DAN,, can you mail me 5ml out of your big jug ... haaaa

Hoping to find a smaller 6ml bottle of instead of a 50ml 60dollar bottle of the stuff.

DAN,, can you mail me 5ml out of your big jug ... haaaa

Last edited:

lilrez

Expert

so, as long as the inner race doesn't slip the shaft and the rotor were good. The o-ring idea is a good one if it helped to tighten it up. Gotta wonder what retaining compound between the inner race and the rotor would do.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Yeah the bearing mount is not easy to find, and also when I found some locally it was not cheap! I suggest trying online as I did, but I was in a hurry and ended up calling several bearing places locally which put me onto a diesel shop that deals with huge truck bearings, and he had it in stock.Looks good. Need to pick up some green goo, trace out dimensions for a future puller, and should be all set..

Hoping to find a smaller 6ml bottle of instead of a 50ml 60dollar bottle of the stuff.

DAN,, can you mail me 5ml out of your big jug ... haaaa

View attachment 148296

BTW let us know how hard of a time you have pressing on the drivers onto that axle. I understand when you buy a new one from Cat/Yam that the drivers comes pre-installed and have heard the drivers can be a real pain to press on. On my 2012 Cat my drivers wore out due to not being extros, and pressing on the new ones was a really hassle.

Dan

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

The rotor is on splines and IMO is not a big deal and is meant to have some play. After I put mine back together with the green, My brake lever had a fair vibration in it initially, which took a ride or two to even out. Likely some green in there i felt.so, as long as the inner race doesn't slip the shaft and the rotor were good. The o-ring idea is a good one if it helped to tighten it up. Gotta wonder what retaining compound between the inner race and the rotor would do.

Dan

Looks good. Need to pick up some green goo, trace out dimensions for a future puller, and should be all set..

Hoping to find a smaller 6ml bottle of instead of a 50ml 60dollar bottle of the stuff.

DAN,, can you mail me 5ml out of your big jug ... haaaa

View attachment 148296

Is that shaft OEM ?

Similar threads

- Replies

- 5

- Views

- 679

- Replies

- 13

- Views

- 2K

- Replies

- 36

- Views

- 6K

- Replies

- 327

- Views

- 58K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.