DC5

TY 4 Stroke Junkie

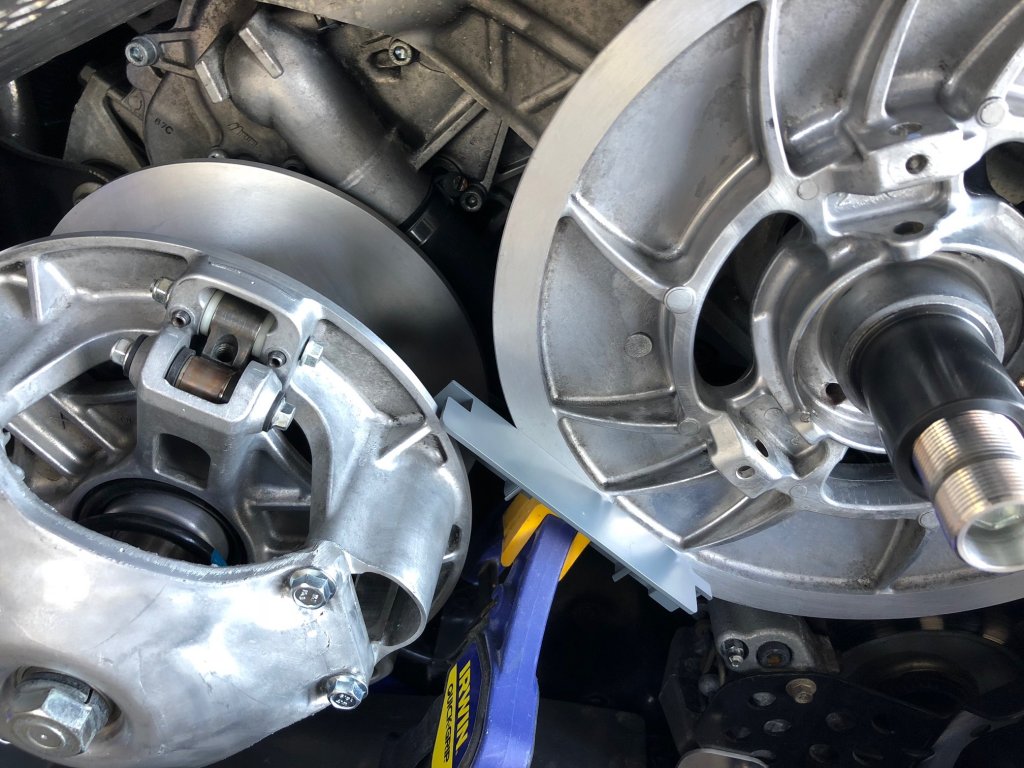

Front mounts are slotted but the rears are not so not really movable but you could get a couple mm either direction.I dont think you would evre be able to get it to 268mm without doing some work to the rear mounts. Also from past experience typically if your centre to centre is short it is because the motor has been pulled towards the secondary and the clutches will no longer be parallel or may appear to be parallel while static but will go out under load. Someone needs to come up with a torque link kit or something like that for the sidewinder to keep everything straight under load. I installed solid motor mounts in my viper to fix the problem but that's no good for a trail sled.

Lusemeat924

Extreme

- Joined

- Jan 1, 2016

- Messages

- 94

- Reaction score

- 24

- Points

- 643

- Location

- Drumbo, Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha Sidewinder 137 XTX SE

268.5mm is the middle spec for 8dn because it’s a longer belt. I believe +/- 2.5mm variation?

262~267mm is the tolerance spec for 8jp. Which puts the middle spec at 264.5mm.

Let’s say your on the low side for the 8jp at 262mm. Be aware that being on the low side of the Center to Center you should compensate your offset to be also on the low side near 58mm.

This will keep the belt straight in the sheaves. Changing your Center to Center or running a different length belt will also change slightly how sled performs/shifts out.

I like to be on the low side of the offset with high horsepower sleds, to much offset is a belt killer causing the secondary to open faster than it should, releasing some belt grip and over shifting.

Great info! I will check my center to center tonight.

rnusr01

Expert

- Joined

- Nov 6, 2016

- Messages

- 397

- Reaction score

- 235

- Points

- 378

- Location

- CT

- Country

- USA

- Snowmobile

- 2021 MXZ-XRS 850

I checked mine after I blew a belt and before I took things apart and it was at 59.95mm with no shim behind secondary. I added shim behind secondary and its now at 60.95. Hope that helps to not blow another belt. Also while I had it all apart I did measurements before secondary was put back together as it made measuring easier.

Last edited:

- Joined

- Apr 14, 2003

- Messages

- 6,539

- Reaction score

- 3,171

- Points

- 1,983

- Location

- Hessel, Michigan

- Country

- USA

- Snowmobile

- Sidewinder, SR Viper XTX, SR Viper XTX, 2016 Apex XTX and Pro-Line Pro Stock 1000

too much offset is a belt killer causing the secondary to open faster than it should, releasing some belt grip and over shifting.

This is different from me...I am at 61.2mm and still on the same belt since asphalt season. This is how I set all my clutch setups I do and only 1 belt blown....but it had 1,400 miles on it.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,517

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

This is different from me...I am at 61.2mm and still on the same belt since asphalt season. This is how I set all my clutch setups I do and only 1 belt blown....but it had 1,400 miles on it.

What’s your Center to Center?

PowderFalcon

Pinnin' it!

- Joined

- Jan 29, 2007

- Messages

- 990

- Reaction score

- 511

- Points

- 1,358

- Location

- Drumbo, ON

- Country

- Canada

- Snowmobile

- 2021 Sidewinder SRX

This is different from me...I am at 61.2mm and still on the same belt since asphalt season. This is how I set all my clutch setups I do and only 1 belt blown....but it had 1,400 miles on it.

im on my second belt in 2500miles. not too bad i think running the same boost as you!

- Joined

- Apr 14, 2003

- Messages

- 6,539

- Reaction score

- 3,171

- Points

- 1,983

- Location

- Hessel, Michigan

- Country

- USA

- Snowmobile

- Sidewinder, SR Viper XTX, SR Viper XTX, 2016 Apex XTX and Pro-Line Pro Stock 1000

What’s your Center to Center?

Haven't checked yet.... My thinking was that the engine was permanently mounted in one position. This is why I would like to see a poll on what everyone's C/C is and who's blowing belts. This all comes down to the assembly people.

Got the aluminum ready, just waiting for CNC time as our shop is mega busy right now.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,517

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

M2c don’t matter

Last edited:

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,517

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Gone gone gone...hey that’s a good tune!

Last edited:

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,517

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Let me clarify “offset situation worse”.

A longer belt will require less offset to run straight in the clutches.

A longer belt will require less offset to run straight in the clutches.

johan

Pro

- Joined

- Jan 19, 2015

- Messages

- 157

- Reaction score

- 103

- Points

- 713

- Location

- sweden

- Country

- Sweden

- Snowmobile

- Viper Xtx mcx 270

Let me clarify “offset situation worse”.

A longer belt will require less offset to run straight in the clutches.

I am with you on this one. I have 0.1mm shim behind my secondary now. And my belt go straight. If I measure on the backside of the secondary the measure is 14.8mm.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,517

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Hey what does Aaen know anyway

Last edited:

Doowithblue

TY 4 Stroke Guru

- Joined

- Mar 17, 2016

- Messages

- 865

- Reaction score

- 568

- Points

- 1,038

- Location

- Waterloo ON

- Country

- Canada

- Snowmobile

- 07 Mach z x (sold)

18- RTX LE

For the record belts are still blowing with dalton b/o and proper deflection.

Soupy

Expert

- Joined

- Jan 10, 2017

- Messages

- 359

- Reaction score

- 84

- Points

- 668

- Location

- West Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX-LE

Yeah Ive blown just as many belts with Dalton components as stock.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,517

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Not worthy

Last edited:

Similar threads

- Replies

- 42

- Views

- 3K

- Replies

- 203

- Views

- 21K

- Replies

- 623

- Views

- 215K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.