Byam

TY 4 Stroke Guru

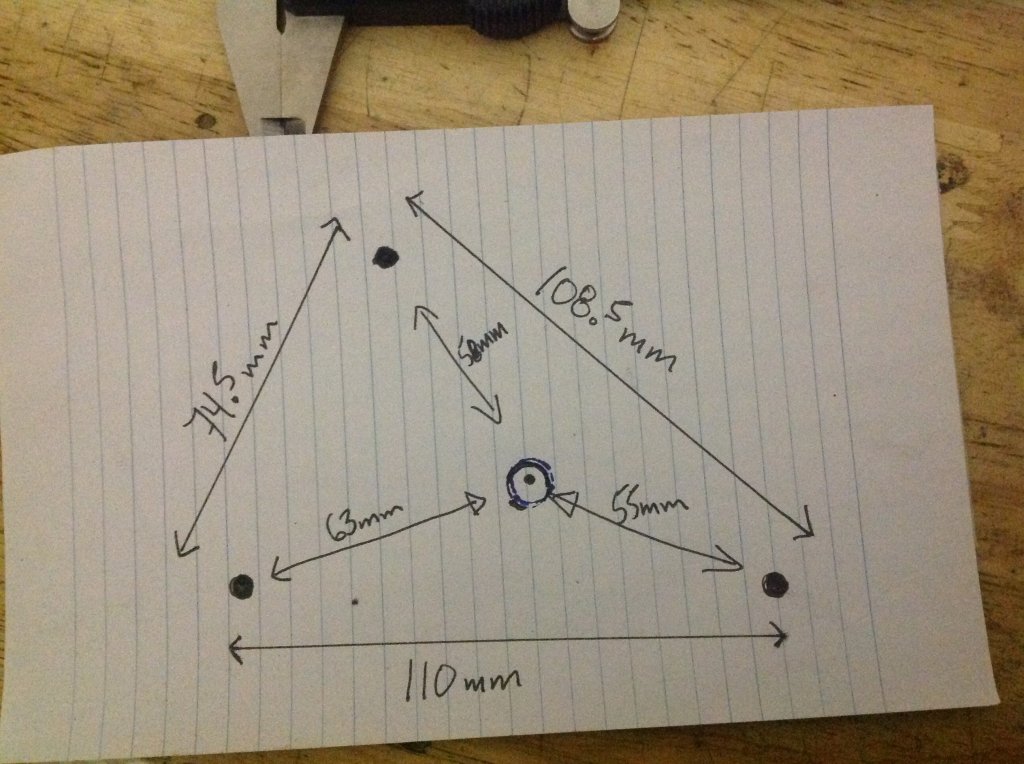

I have this puller because heat was not enough one time and i have bend the caliper:-/ whit this type of puller its a piece of cake to pull out! STRAIGHT....

Approximately 2/3mm. It doesn't need to be perfect to work well. As you guys can see i am not an engineer

Yes I agree, once you look this bearing in place with compound or other methods, how does one plan to remove it? It was a slip fit design for a reason. With compound is just a little heat required to soften it up so removal of the bearing can happen?

Approximately 2/3mm. It doesn't need to be perfect to work well. As you guys can see i am not an engineer

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

X2Yes, apply some heat inside end of track shaft (it's hollow). That will soften loctite. Some build a puller that uses the same 3 bolt holes that hold the casting piece to the tunnel. Either way, it's not that hard to get off. I'd rather put up with having to get it off than having the track shaft destroyed and/or the brake rotor too.

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,758

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

So I just checked to see if my puller with the 3 slots would fit that template - Nope - not even close. Cant catch a break with this sled. Its like Cat doesn't want a soul to be able to easily work on this thing......

Thanks Byam for posting this.

Looks like I am off to get a half inch plate and rig up a puller frame.

MS

Thanks Byam for posting this.

Looks like I am off to get a half inch plate and rig up a puller frame.

MS

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Travis would be the perfect choice to design/build a nice caliper puller for our sleds. I hope he is watching and has time, then we could just spread on some bearing mount when sleds are newer, and puller would be used with some heat.

Travis are you following this?

Dan

Travis are you following this?

Dan

geez150

Expert

Forgive me for my ignorance, but that puller is just for removing the brake rotor?

I have this puller because heat was not enough one time and i have bend the caliper:-/ whit this type of puller its a piece of cake to pull out! STRAIGHT....

View attachment 148134 View attachment 148135 View attachment 148136

Approximately 2/3mm. It doesn't need to be perfect to work well. As you guys can see i am not an engineer

View attachment 148146

Byam

TY 4 Stroke Guru

No igorance budy.... Its for removing the bearing and back piece of the brake when glued! You have to split the caliper in half then use the 3 bolt of the puller in the back piece holding the bearing! the big bolt and a little plate behind against the drive shaft, everything comes straight. Heat is still neededForgive me for my ignorance, but that puller is just for removing the brake rotor?

Last edited:

02ViperMody44

Lifetime Member

- Joined

- Jan 26, 2009

- Messages

- 582

- Location

- Utica, NY

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

2013 Yamaha XTX

- LOCATION

- Old Forge, NY

- YAHOO

- ramody44@yahoo.com

I would be interested in one if you did make one Travis!

IH8CROWS

Expert

I would also be interested in one.

putz21

VIP Member

- Joined

- Apr 15, 2013

- Messages

- 645

- Location

- Tomahawk, WI

- Country

- USA

- Snowmobile

- '23 Sidewinder LTX LE w/EPS

‘19 Sidewinder LTX SE

Me too!

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,661

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

Me too, unless the engineers decide to fix it. It would be wonderful to not need one.

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,758

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

Forgive me for my ignorance, but that puller is just for removing the brake rotor?

Once the caliper is split and disc removed this puller will drag the bearing mount assembly off the shaft. For the guys that plan on loctiting the bearing to the shaft this is the best way to get the mount off the shaft imo.

MS

number1kyster

TY 4 Stroke God

I'd rather see Travis come up with something that would eliminate the need for bearing retainer in the first place.

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,288

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

Why are guys screwing with Loctite and pullers? Put a set screw in and forget it!!!!!

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,661

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

Dumb question but does a set screw cause any offset to center? I.e. if there is any clearance between ID of bearing and OD of track shaft, when you tighten a set screw into the ID of bearing, wouldn't that cause a small offset situation? The set screw pushes the track shaft over to the opposite side of the ID of the bearing thereby causes eccentricity?

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,288

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

In theory I guess so. How far does really travel? Does it effect anything? I would say no, I ran it on mine for 5k miles with no issues. I replaced left side bearing as precautionary measure before a trip and the right side lower bearing is original.

If you want put 2 screws in opposite of each other.

If you want put 2 screws in opposite of each other.

Similar threads

- Replies

- 5

- Views

- 679

- Replies

- 13

- Views

- 2K

- Replies

- 36

- Views

- 6K

- Replies

- 327

- Views

- 58K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.